Lithium ion battery composite positive electrode material and preparation method

A composite cathode material, lithium-ion battery technology, applied in battery electrodes, lithium storage batteries, secondary batteries, etc., can solve the problem of thick coating thickness, the coating layer cannot take into account the dynamic performance and electrochemical stability, and increase the internal resistance. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method for a lithium-ion battery composite cathode material, comprising the following steps:

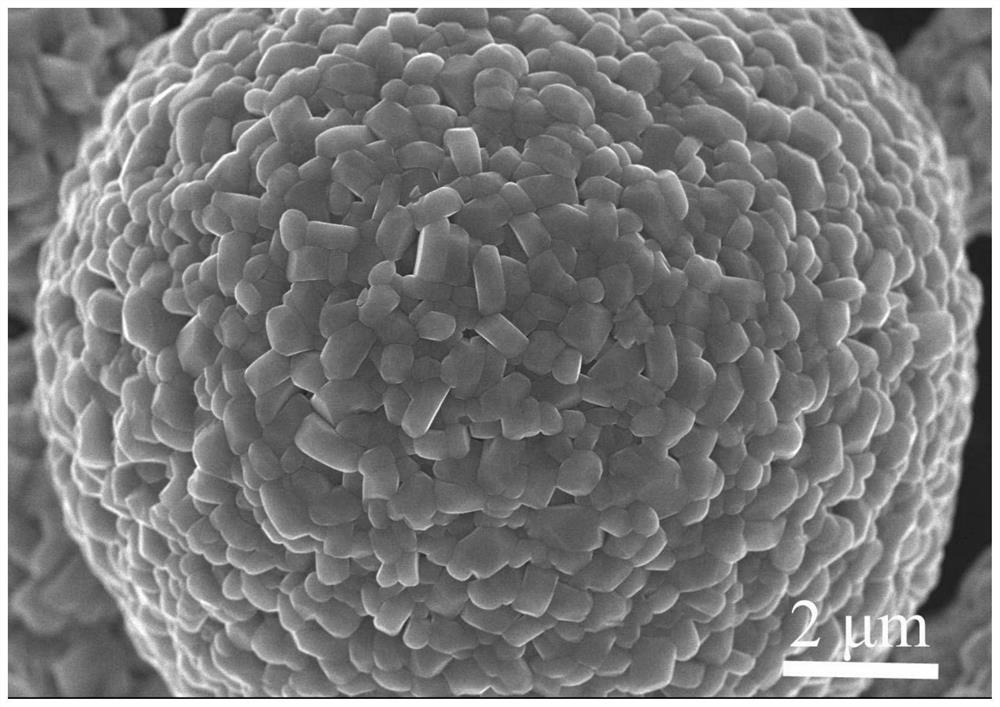

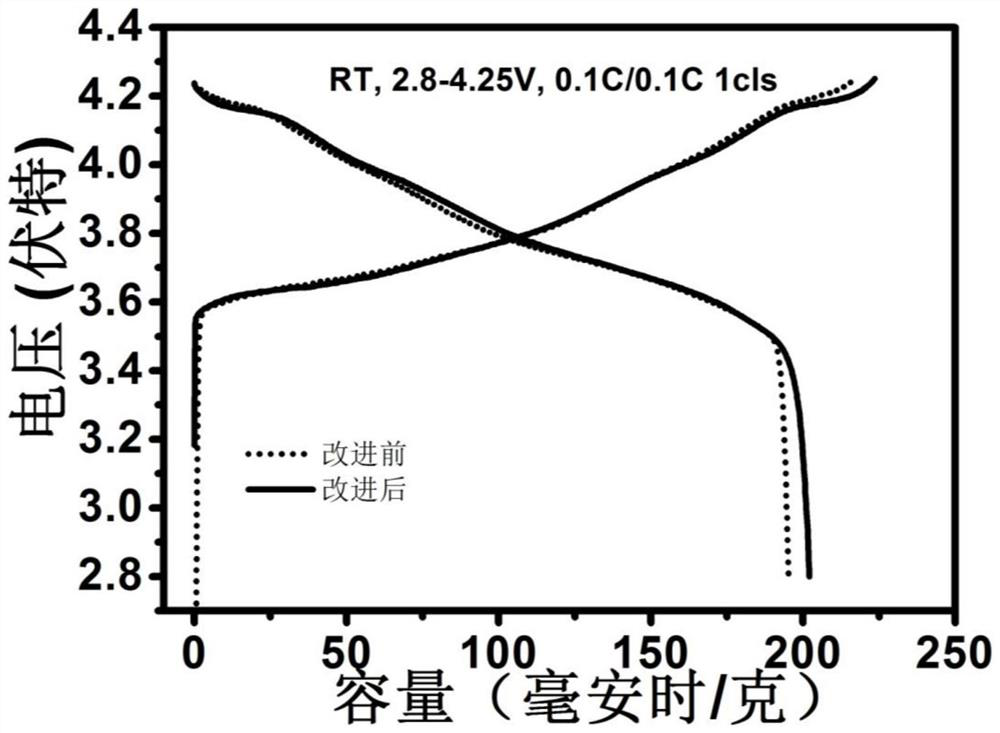

[0041] (1) The bulk cathode material used in this example is LiNi with a median particle size of about 10 μm 0.8 co 0.1 mn 0.1 o 2 (sample before improvement), its SEM image is as figure 1 shown.

[0042] Add 0.02mol of ammonium dihydrogen phosphate, 0.02mol of ferrous oxalate and 0.02mol of lithium acetate into water, mix well and react completely; then add 0.028mol of lithium acetate and 0.007mol of pyrophosphoric acid, mix well and then add 1mol of LiNi 0.8 co 0.1 mn 0.1 o 2 , to obtain the positive electrode material mixture after drying.

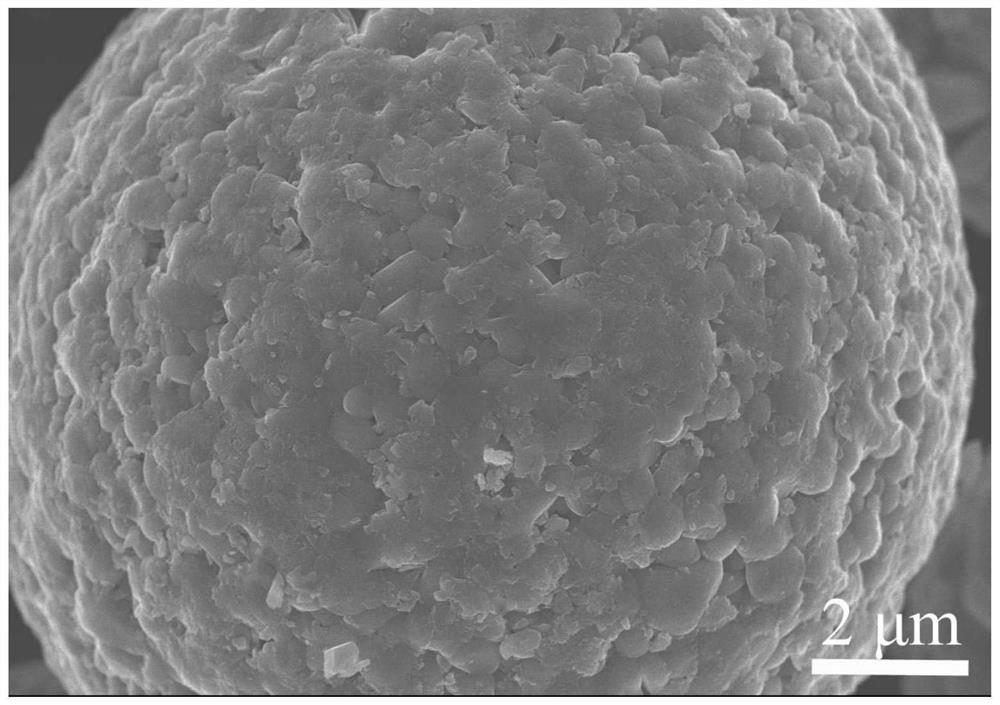

[0043] (2) Put the above positive electrode material mixture in a nitrogen atmosphere and calcined at 720°C for 10h to obtain a lithium ion battery composite positive electrode material (improved sample) coated with a composite coating layer, wherein the composite coating layer is in the composite positive electrod...

Embodiment 2

[0053] A preparation method for a lithium-ion battery composite cathode material, comprising the following steps:

[0054] (1) The bulk cathode material used in this example is LiCoO with a median particle size of about 10 μm 2 sample.

[0055] Add 0.02mol of ammonium dihydrogen phosphate, 0.02mol of ferrous oxalate and 0.02mol of lithium acetate into water, mix well and react completely; then add 0.028mol of lithium acetate and 0.007mol of pyrophosphoric acid, mix well and then add 1mol of LiCoO 2 , to obtain the positive electrode material mixture after drying.

[0056] (2) The above positive electrode material mixture was placed in a nitrogen atmosphere and calcined at 720° C. for 10 h to obtain a lithium ion battery composite positive electrode material coated with a composite coating layer.

Embodiment 3

[0060] A preparation method for a lithium-ion battery composite cathode material, comprising the following steps:

[0061] (1) The bulk cathode material used in this example is LiNiO with a median particle size of about 10 μm 2 sample.

[0062] Add 0.02mol of ammonium dihydrogen phosphate, 0.02mol of ferrous oxalate and 0.02mol of lithium acetate into water, mix well and react completely; then add 0.028mol of lithium acetate and 0.007mol of pyrophosphoric acid, mix well and add 1mol of LiNiO 2 , to obtain the positive electrode material mixture after drying.

[0063] (2) The above positive electrode material mixture was placed in a nitrogen atmosphere and calcined at 720° C. for 10 h to obtain a lithium ion battery composite positive electrode material coated with a composite coating layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com