Preparation method of MOF-derived high-activity Ni single-atom oxygen reduction reaction electrocatalyst

An electrocatalyst, high activity technology, applied in circuits, electrical components, battery electrodes, etc., can solve the problems of slow application, poor stability and high cost of fuel cells, and achieve the effect of strong applicability, easy operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

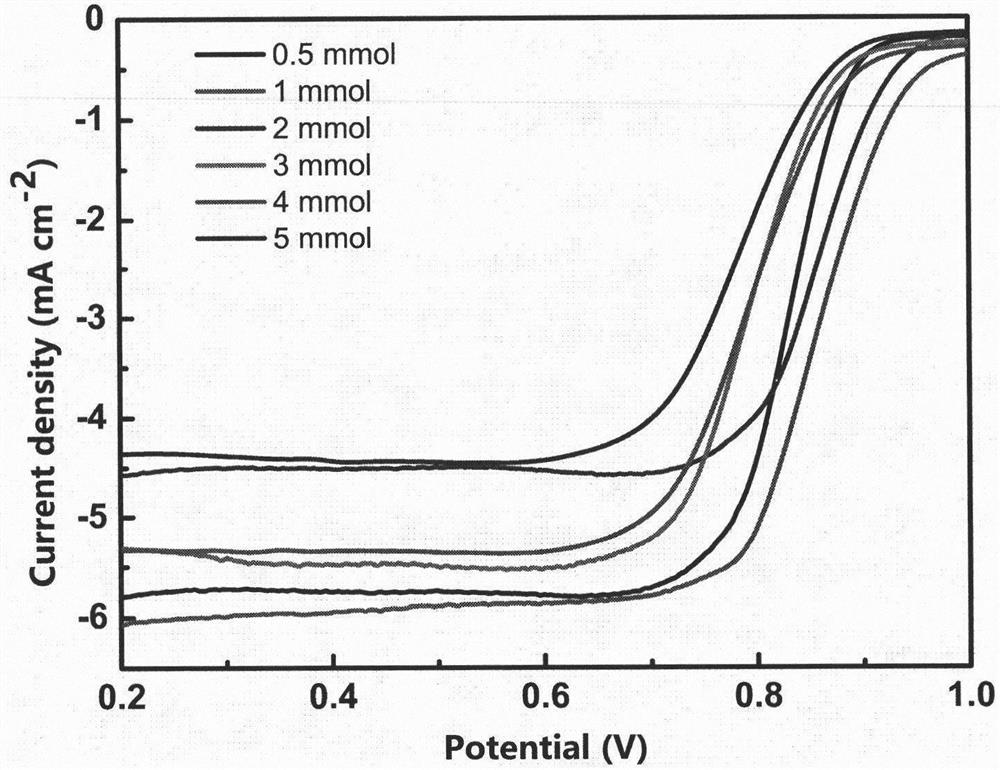

[0027] MOF-derived Ni single-atom high-activity ORR electrocatalyst: Dissolve 4mmol zinc nitrate hexahydrate, 1mmol o-phenanthroline, and 20mmol 2-methylimidazole in 50ml, 40ml, and 50ml methanol respectively to obtain A, B, and C solutions. After stirring evenly, add 1 mmol of nickel acetate tetrahydrate to solution A, then add solution B and solution C to solution A respectively, and stir magnetically at room temperature for 6 hours to obtain a precipitate; separate the precipitate by centrifugation, and use methanol The solution was washed 3 times; the washed sample was put into an oven for drying; the dried sample was transferred to a tube furnace, fed with hydrogen-argon mixed gas, and calcined at 1000°C for 3 hours to obtain the final product.

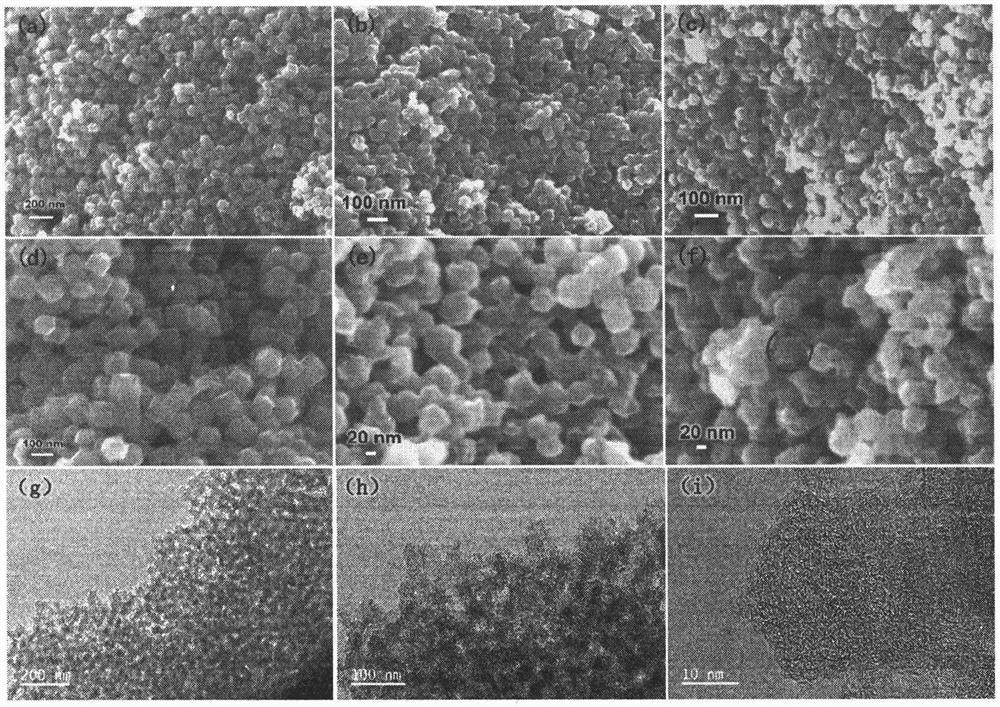

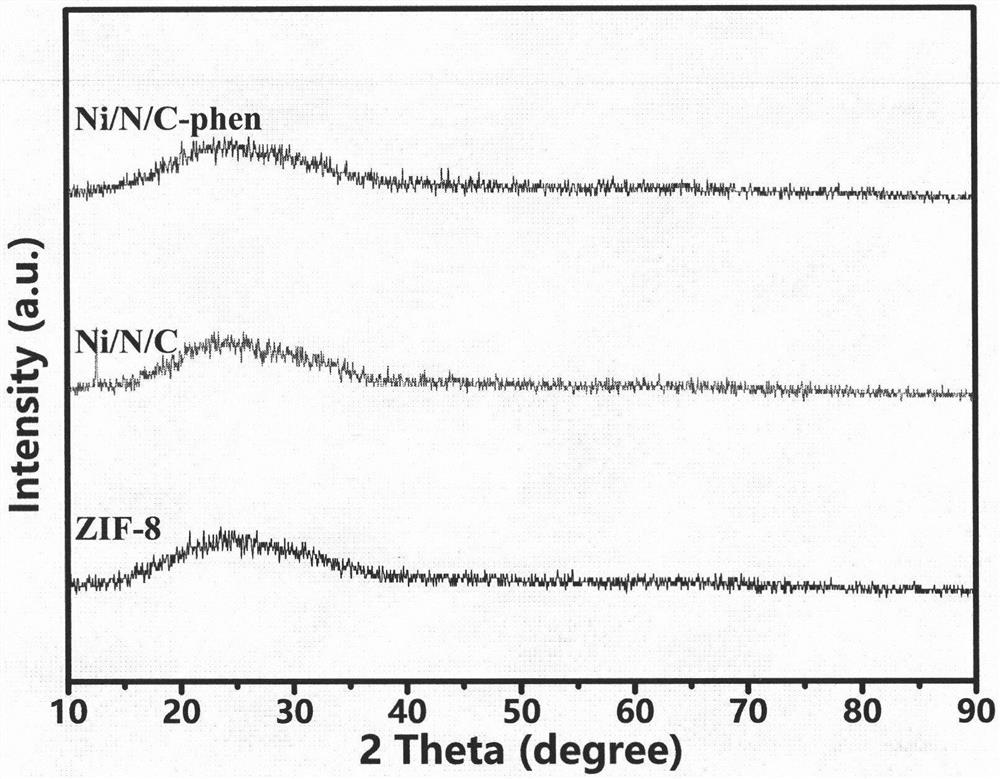

[0028] figure 1 a-1f are SEM pictures of the product prepared in Example 1. figure 1 a and figure 1 d shows that the ZIF-8 precursor presents a regular dodecahedral structure, and the side length of a single dodecahedron is ~11...

Embodiment 2

[0031] The addition of o-phenanthroline is 0.5mmol, and other conditions are the same as in Example 1.

Embodiment 3

[0033] The addition of o-phenanthroline is 2mmol, and other conditions are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com