An electrolyte additive and electrolyte and lithium ion battery containing the additive

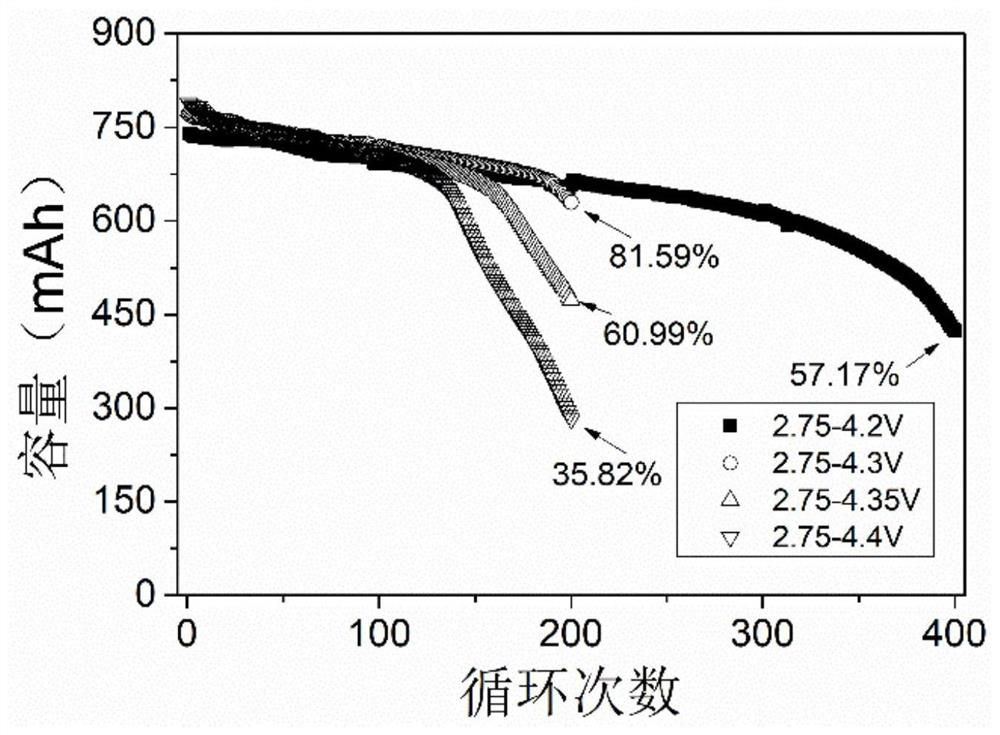

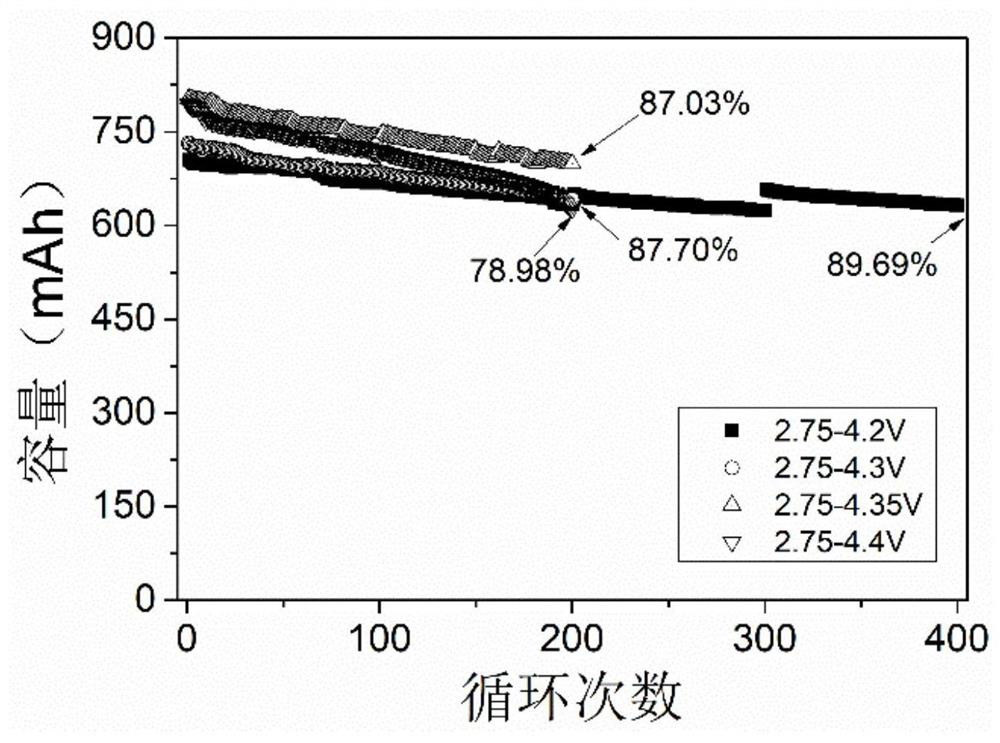

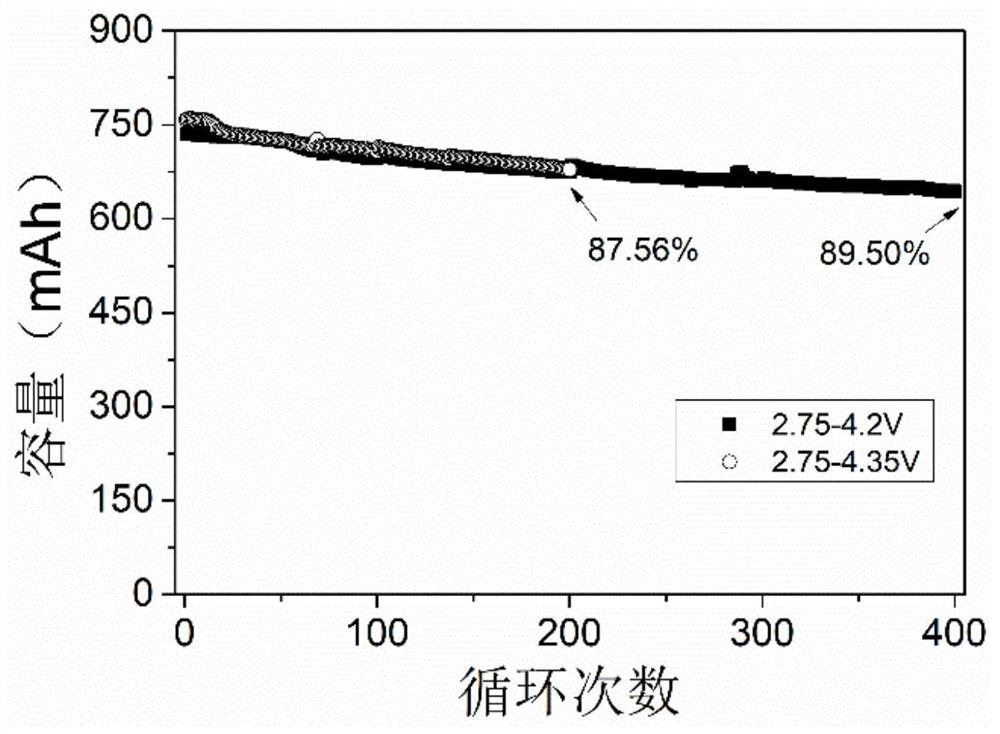

An electrolyte additive, lithium-ion battery technology, applied in the field of lithium-ion battery, electrolyte, electrolyte additive, can solve the problems of short life, poor battery safety and stability, etc., to improve pressure resistance, good electrochemical performance, capacity The effect of retention rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The chemical formula of the electrolyte additive used in this example is C 15 H 4 F 17 NS 2 , the structural formula is:

[0042]

[0043] The preparation process of the additive is as follows:

[0044] 2-mercaptobenzothiazole (0.4 mmol), perfluoro-n-octyl iodide (0.6 mmol), tetramethylethylenediamine TMEDA (0.6 mmol) and 5 mL of acetonitrile were added to a clean pressure-resistant tube, respectively. Subsequently, the reaction mixture was stirred under light for 2 hours. After the reaction was completed, 10 mL of deionized water was added, extracted three times with 15 mL of dichlorohexane or ethyl acetate, the organic phases were combined, washed once with deionized water and brine respectively, and washed with anhydrous Na 2 SO 4 Drying, filtration, rotary evaporation to remove the solvent, and purification by silica gel column chromatography can obtain the perfluoro-substituted electrolyte additive with the corresponding carbon chain length.

[0045] The ...

Embodiment 2

[0049] The chemical formula of the electrolyte additive used in this example is C 11 H 4 F 9 NS 2 , the structural formula is:

[0050]

[0051] The preparation process of the additive is as follows:

[0052] 2-mercaptobenzothiazole (0.4 mmol), perfluoro-n-butyl iodide (0.6 mmol), tetramethylethylenediamine TMEDA (0.6 mmol) and 5 mL of acetonitrile were added to a clean pressure-resistant tube, respectively. Subsequently, the reaction mixture was stirred under light for 2 hours. After the reaction was completed, 10 mL of deionized water was added, extracted three times with 15 mL of dichlorohexane or ethyl acetate, the organic phases were combined, washed once with deionized water and brine respectively, and washed with anhydrous Na 2 SO 4 Drying, filtration, rotary evaporation to remove the solvent, and purification by silica gel column chromatography can obtain the perfluoro-substituted electrolyte additive with the corresponding carbon chain length.

[0053] The m...

Embodiment 3

[0057] The chemical formula of the electrolyte additive used in this example is C 13 H 4 F 13 NS 2 , the structural formula is:

[0058]

[0059] The preparation process of the additive is as follows:

[0060] 2-mercaptobenzothiazole (0.4 mmol), perfluoro-n-hexyl iodide (0.6 mmol), tetramethylethylenediamine TMEDA (0.6 mmol) and 5 mL of acetonitrile were added to a clean pressure-resistant tube, respectively. Subsequently, the reaction mixture was stirred under light for 2 hours. After the reaction was completed, 10 mL of deionized water was added, extracted three times with 15 mL of dichlorohexane or ethyl acetate, the organic phases were combined, washed once with deionized water and brine respectively, and washed with anhydrous Na 2 SO 4 Drying, filtration, rotary evaporation to remove the solvent, and purification by silica gel column chromatography can obtain the perfluoro-substituted electrolyte additive with the corresponding carbon chain length.

[0061] Asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com