Teicoplanin preparation for injection and preparation method thereof

A technology of teicoplanin and injection preparation, applied in the field of medicine, can solve the problems of low yield, low purity, poor clarity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

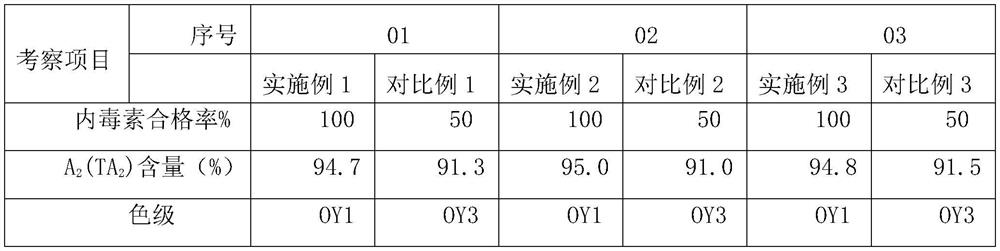

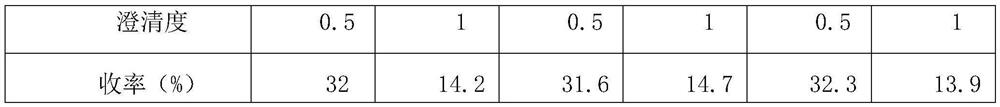

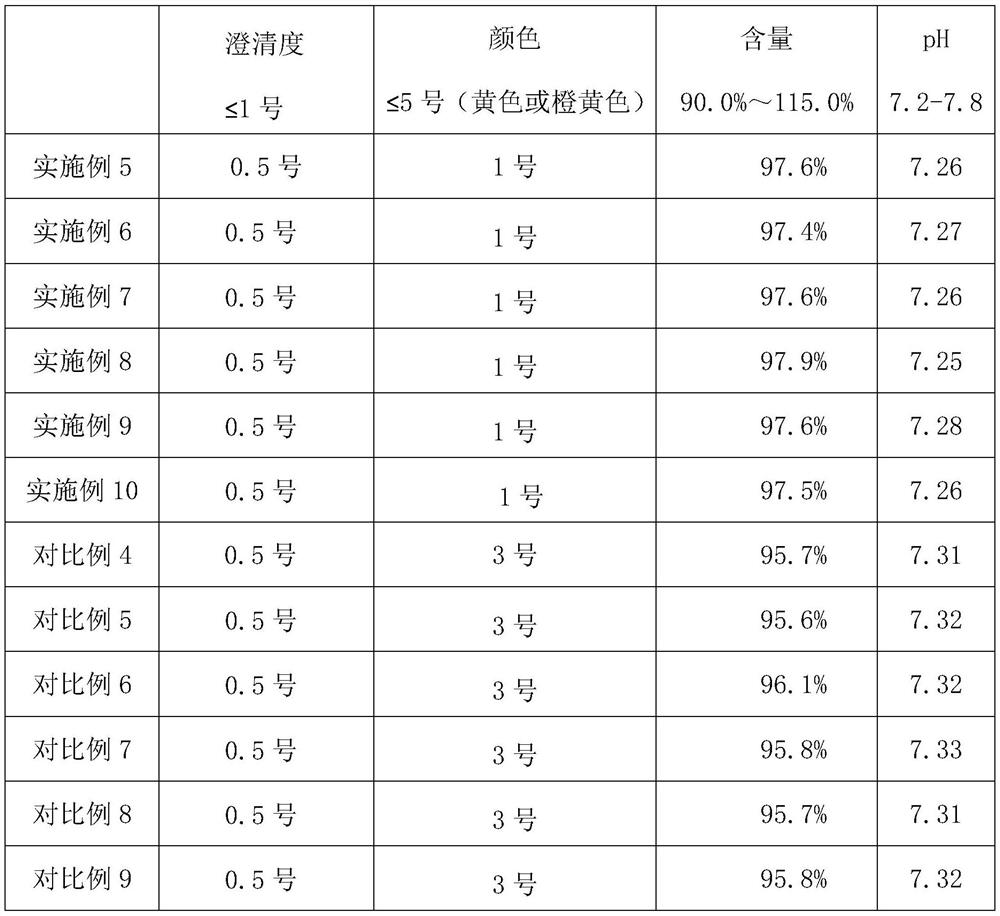

Examples

Embodiment 1

[0037] A. Adsorption: Teicoplanin fermentation filtrate totals 23.4 billion units, desorbs through macroporous adsorption resin to obtain a total of 16.97 billion units of teicoplanin raw material liquid;

[0038] B. Decolorization: Add 5.1 kilograms of 0.3% 767 injection activated carbon and 5.1 kilograms of 0.3% imported FSAC-01 activated carbon to the above-mentioned teicoplanin raw material solution for decolorization, and the total decolorization solution is 15.34 billion;

[0039] C. DAC column chromatography, the filler is polymer reversed-phase chromatography filler UniPs30-300, the teicoplanin filtrate is eluted through the column, and the total eluent collected is 8.37 billion;

[0040] D. Membrane system concentration: After the chromatographic solution is concentrated by ultrafiltration and then nanofiltration, the concentrated solution is washed with purified water to remove residual solvents, and a total of 8 billion teicoplanin concentrated solutions are obtained...

Embodiment 2

[0043] A. Adsorption: Teicoplanin fermentation filtrate has a total of 25.5 billion units, and a total of 20.87 billion units of desorption liquid is obtained by adsorption and desorption of macroporous adsorption resin;

[0044] B. Decolorization: Add 6.2 kg of 0.3% domestic activated carbon and 6.2 kg of 0.3% imported FSAC-01 activated carbon for decolorization, and the total decolorization solution is 15.9 billion;

[0045] C. DAC column chromatography, the filler is polymer reversed-phase chromatography filler UniPs30-300, and the decolorization solution is obtained by chromatography with a suitable chromatographic solution totaling 8.3 billion;

[0046]D. Membrane system concentration: After the chromatographic solution is concentrated by ultrafiltration and then nanofiltration, the molecular weight cut-off of the ultrafiltration membrane is 5000-10000 Daltons, and the molecular weight cut-off of the nanofiltration membrane is 200-300 Daltons. The concentrated solution is ...

Embodiment 3

[0049] A. Adsorption: Teicoplanin fermentation filtrate has a total of 26.6 billion units, and a total of 21.1 billion units of desorption liquid has been obtained by adsorption and desorption of macroporous adsorption resin;

[0050] B. Decolorization: Add 6.3 kg of 0.3% domestic activated carbon and 6.3 kg of 0.3% imported FSAC-01 activated carbon for decolorization, and the total decolorization solution is 15.77 billion;

[0051] C. Chromatography: the decolorized solution is obtained by chromatography with a suitable chromatographic solution totaling 7.9 billion;

[0052] D. Membrane system concentration: After the chromatographic solution is concentrated by ultrafiltration and then nanofiltration, the molecular weight cut-off of the ultrafiltration membrane is 5000-10000 Daltons, and the molecular weight cut-off of the nanofiltration membrane is 200-300 Daltons. The concentrated solution is washed with purified water Residual solvent was removed to obtain a total of 7.4 b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com