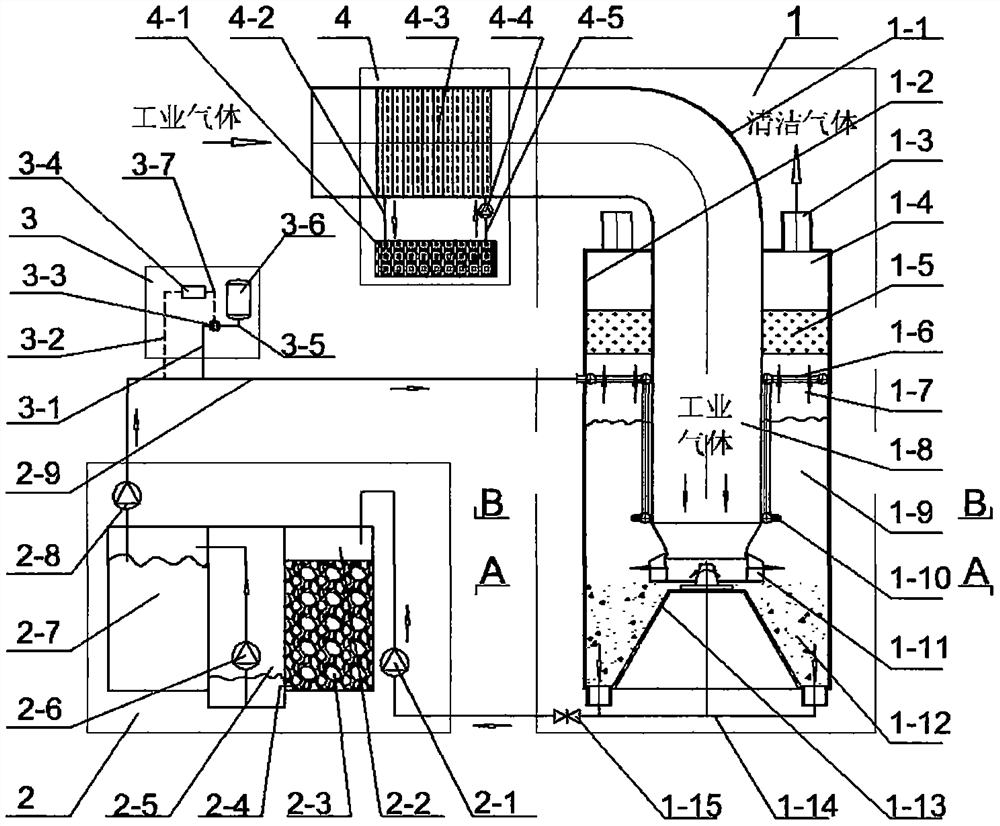

System and method for purifying industrial gas in gas explosion mode

An industrial gas and gas explosion technology, applied in chemical instruments and methods, separation methods, gas treatment and other directions, can solve the problems of substandard discharge of harmful substances and high operating costs, avoid secondary environmental pollution, increase economic benefits, and occupy less land effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

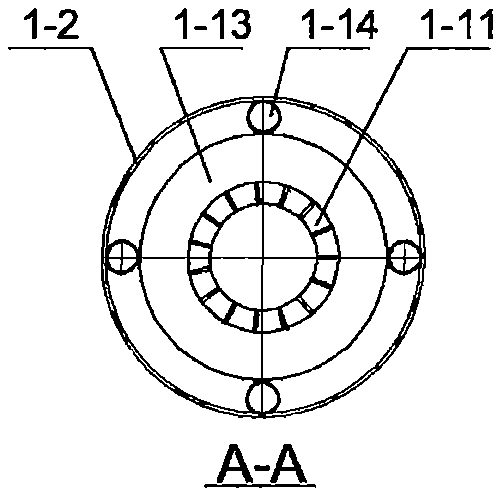

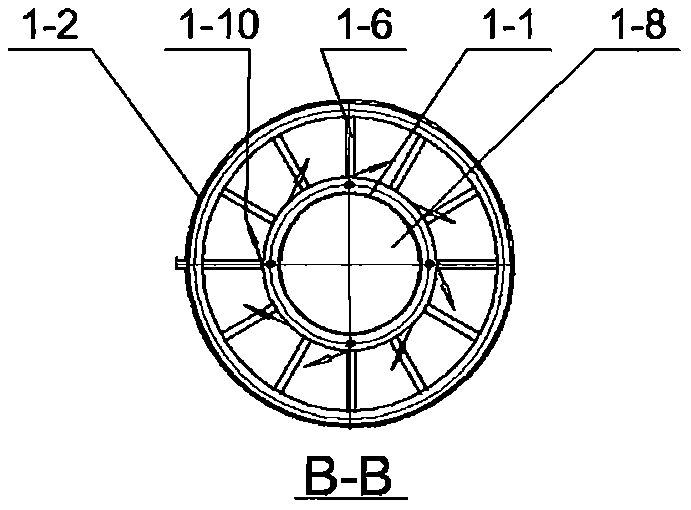

Method used

Image

Examples

Embodiment example

[0064] 1) SO in industrial gases 2 and NO X , in contact with water in the explosion chamber, the SO in it 2 and NO X It is converted into weakly acidic water mixed with sulfurous acid water and nitrous acid water, and then neutralized and filtered by the liquid-pollution separation unit containing alkaline filter material, and the weakly acidic water is converted into neutral water with moderate acidity and alkali for reuse. The gas is transformed into clean gas after explosive gas purification and then discharged.

[0065] 2) The residual water vapor in the industrial gas is in contact with water in the gas explosion chamber, and the water molecules of the water vapor are dissolved in the water, and the gas is converted into clean gas after the gas explosion purification treatment and then discharged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com