Formula and preparation process of novel powder cement grinding aid

A cement grinding aid and preparation technology, which is applied in the field of cement grinding aids, can solve the problems of powder grinding aids such as single variety and function, limited wide-scale use, and poor chemical stability, so as to increase the antioxidant performance and chemical stability. Improvement of stability and reduction efficiency, effect of reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 3 parts of Diethanol Monoisopropanolamine, 7 parts of Potassium Humate, 3 parts of Sodium Thiocyanate, 32 parts of Yuanming powder, 28 parts of silica fume, 20 parts of hexavalent chromium reducer, 7 parts of stabilizer.

[0029] The hexavalent chromium reducing agent is 6 parts of stannous sulfate, 10 parts of ferrous sulfate, and 4 parts of manganese acetate.

[0030] The stabilizer is 5 parts of sodium lignosulfonate, 1 part of anhydrous calcium sulfate, and 1 part of calcium stearate.

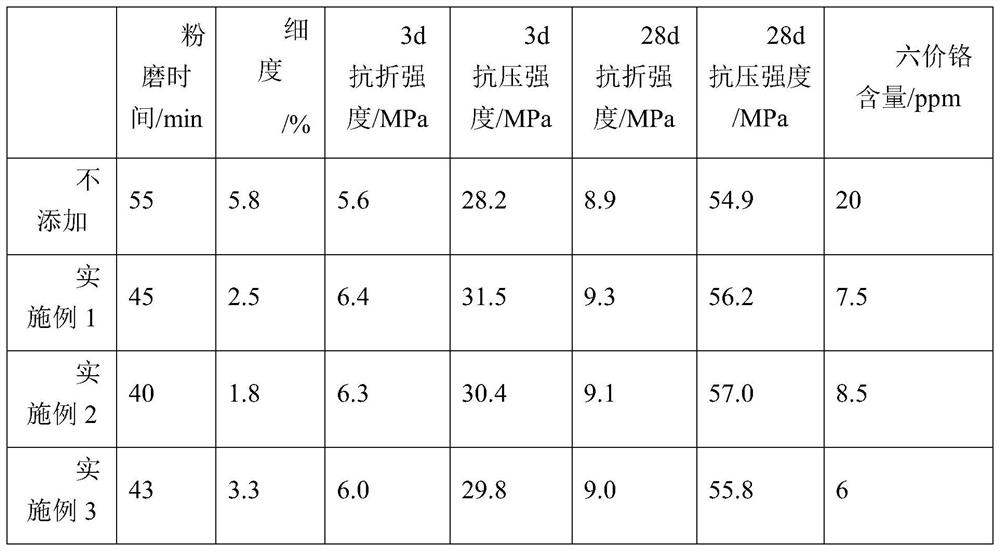

[0031] The proportion of cement is 65% of cement clinker; 5% of gypsum; 22% of slag; 3% of fly ash and 5% of stone powder. When the grinding time is 45 minutes and the fineness is 2.5%, the cement obtained after hardening The 3d flexural strength is 6.4MPa, the 3d compressive strength is 31.5MPa, the 28d flexural strength is 9.3MPa, the 28d compressive strength is 56.2MPa, and the hexavalent chromium content is 7.5ppm.

Embodiment 2

[0033] 2 parts of Diethanol Monoisopropanolamine, 3 parts of triglycerin, 5 parts of Potassium Humate, 4 parts of Sodium Thiocyanate, 25 parts of Yuanming powder, 35 parts of silica fume, 17 parts of hexavalent chromium reducer, stabilizer 9 servings.

[0034] The hexavalent chromium reducing agent is 3 parts of stannous sulfate, 12 parts of ferrous sulfate, and 2 parts of manganese acetate.

[0035] The stabilizer is 6 parts of sodium lignosulfonate, 2 parts of anhydrous calcium sulfate, and 1 part of calcium stearate.

[0036] The proportion of cement is 65% of cement clinker; 5% of gypsum; 22% of slag; 3% of fly ash and 5% of stone powder. When the grinding time is 40 minutes and the fineness is 1.8%, the 3d cement obtained after hardening The flexural strength is 6.3MPa, the 3d compressive strength is 30.4MPa, the 28d flexural strength is 9.1MPa, the 28d compressive strength is 57MPa, and the content of hexavalent chromium is 8.5ppm.

Embodiment 3

[0038] 3 parts of Diethanol Monoisopropanolamine, 1 part of Tripolyglycerin, 9 parts of Potassium Humate, 2 parts of Sodium Thiocyanate, 20 parts of Yuanming Powder, 30 parts of Silica Fume, 25 parts of Hexavalent Chromium Reducer, Stabilizer 10 servings.

[0039] The hexavalent chromium reducing agent is 7.5 parts of stannous sulfate, 12.5 parts of ferrous sulfate, and 5 parts of manganese acetate.

[0040] The stabilizer is 8 parts of sodium lignosulfonate, 1.5 parts of anhydrous calcium sulfate, and 0.5 part of calcium stearate.

[0041] The proportion of cement is 65% of cement clinker; 5% of gypsum; 22% of slag; 3% of fly ash and 5% of stone powder. When the grinding time is 43 minutes and the fineness is 3.3%, the cement obtained after hardening The 3d flexural strength is 6.0MPa, the 3d compressive strength is 29.8Pa, the 28d flexural strength is 9.0MPa, the 28d compressive strength is 55.8MPa, and the content of hexavalent chromium is 6ppm.

[0042] For the preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com