Silicon-carbon composite material, and preparation method and application thereof

A technology of silicon-carbon composite materials and carbon sources, applied in nanotechnology, nanotechnology, structural parts, etc. for materials and surface science, can solve problems such as unsuitable preparation process, poor cycle stability, and low tap density. Achieve the effects of good industrialization prospect, low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

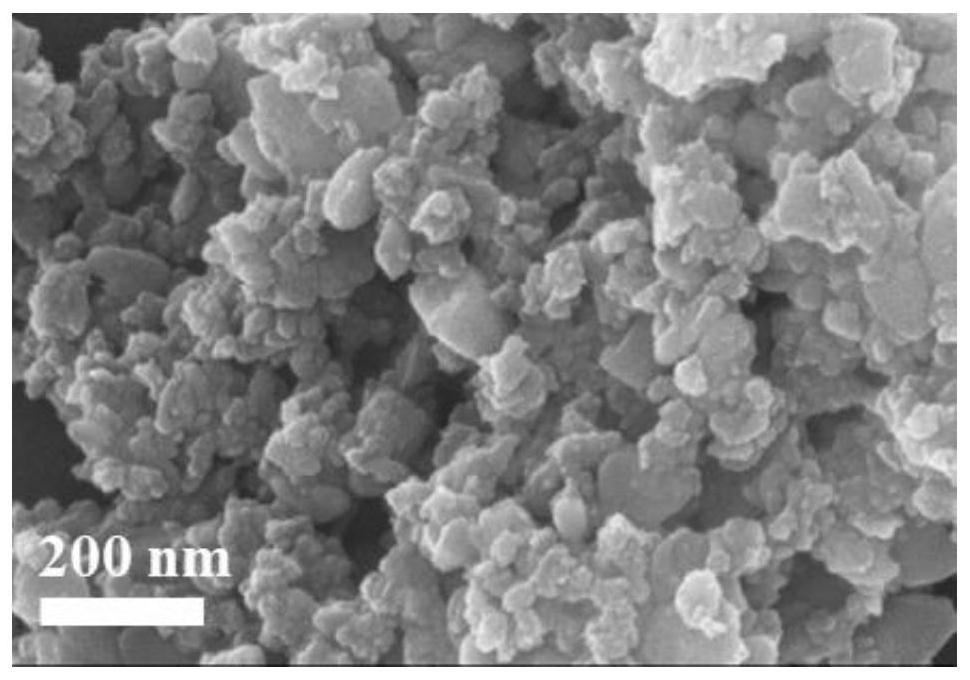

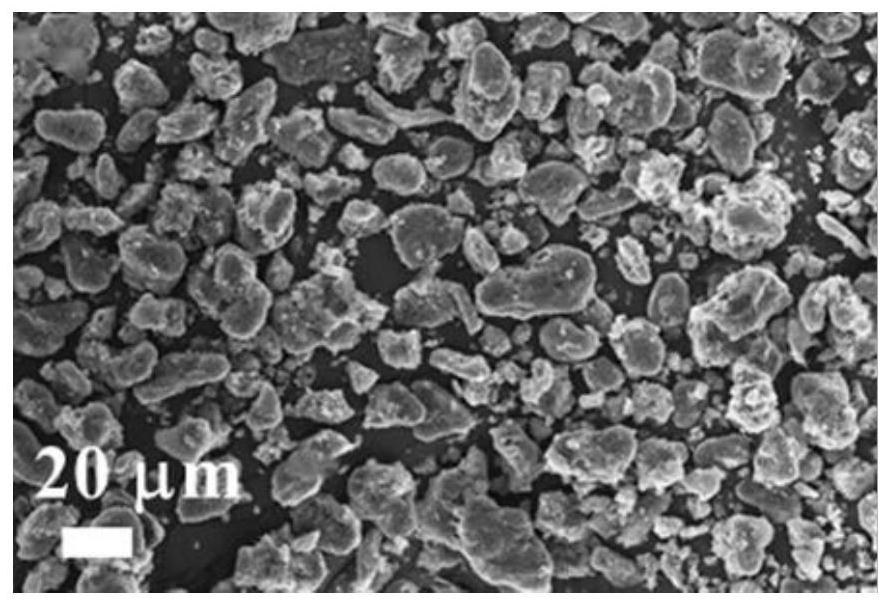

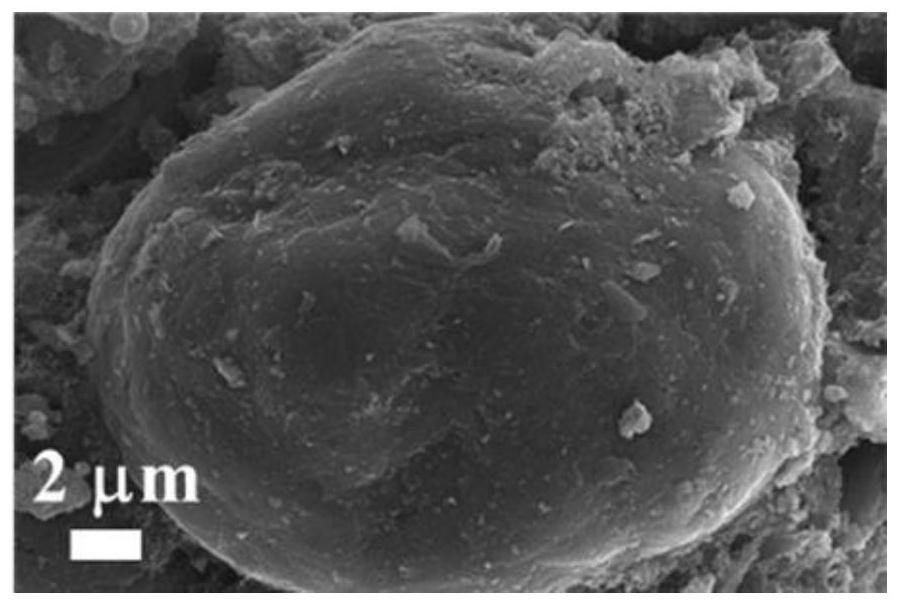

[0033] The first aspect of the present invention provides a method for preparing a silicon-carbon composite material, comprising the following steps: pulverizing and dealloying a silicon-based alloy to obtain micron silicon powder; dispersing the micron silicon powder in a solution containing a first carbon source, After pulverization, the nano-silicon slurry with primary coating is obtained; the nano-silicon slurry is mixed with the second carbon source, stirred evenly, dried and roasted to obtain the precursor of the secondary coating; the precursor is in the atmosphere of the third carbon source Under chemical vapor deposition, a three-level coated silicon-carbon composite material is obtained.

[0034] According to the present invention, as mentioned above, there is a silicon-carbon composite technology using nano-silicon to improve the volume expansion of silicon during charging and discharging, so as to improve the cycle stability of the material. However, nano-silicon o...

Embodiment 1

[0056] (1) Put 50g of Al-Si alloy block (Si content is 60wt%) in the ball mill pot, put stainless steel grinding balls in the ratio of 15:1 according to the mass ratio of ball to material, feed nitrogen as protective gas, and then use 200rpm ball milling at a high speed for 24 hours to obtain Al-Si alloy powder. Add Al-Si alloy powder to a concentration of 1mol L -1 etched in hydrochloric acid, filtered, washed with water, and dried in vacuum at 50°C to obtain micron silicon powder;

[0057] (2) Take 100g of citric acid and dissolve it in 2L of isopropanol, then add 100g of the micron silicon powder prepared in step (2), mix it uniformly by ultrasonic, pour it into the dispersion tank of a sand mill, and sand mill it at 2300rpm for 8h under the protection of nitrogen After taking out, obtain the nano-silicon slurry coated with citric acid;

[0058] (3) Put 14g of spherical graphite and 4g of asphalt into 150mL of the slurry prepared in step (2), stir and mix evenly, then dry...

Embodiment 2

[0064] (1) Put 50g of Fe-Si alloy block (Si content is 75wt%) in the ball mill jar, put stainless steel grinding balls in the ratio of 20:1 according to the mass ratio of ball to material, feed nitrogen as protective gas, and then use 400rpm ball milling for 12 hours at a high speed to obtain Fe-Si alloy powder. Add Fe-Si alloy powder to a concentration of 2mol L -1 etched in hydrochloric acid, filtered, washed with water, and dried in vacuum at 50°C to obtain micron silicon powder;

[0065] (2) Take 100g of glucose and dissolve it in 2L of ethanol, then add 100g of micron silicon powder prepared in step (2), mix it uniformly by ultrasonic, pour it into the dispersion tank of a sand mill, and take it out after sand milling at 2500rpm for 4 hours under the protection of nitrogen. Obtain the nano-silicon slurry coated with glucose;

[0066] (3) Put 15g of spherical graphite and 5g of asphalt into 150mL of the slurry prepared in step (2), stir and mix evenly, then dry, and fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com