Bio-based gel polymer electrolyte and preparation method thereof

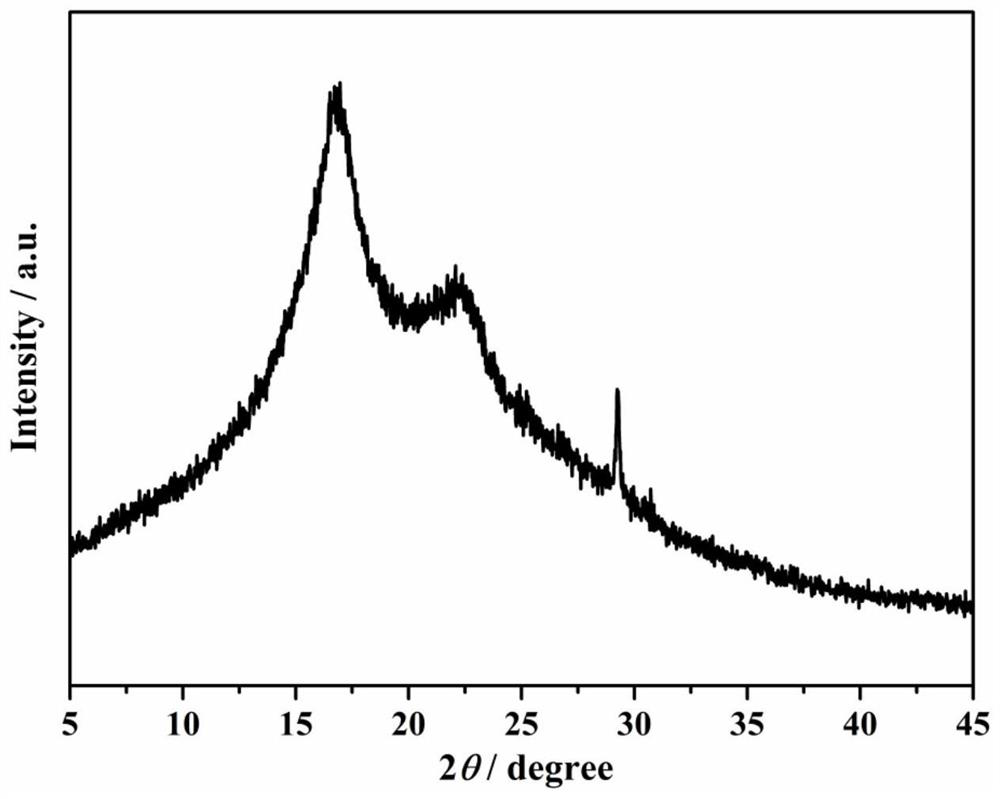

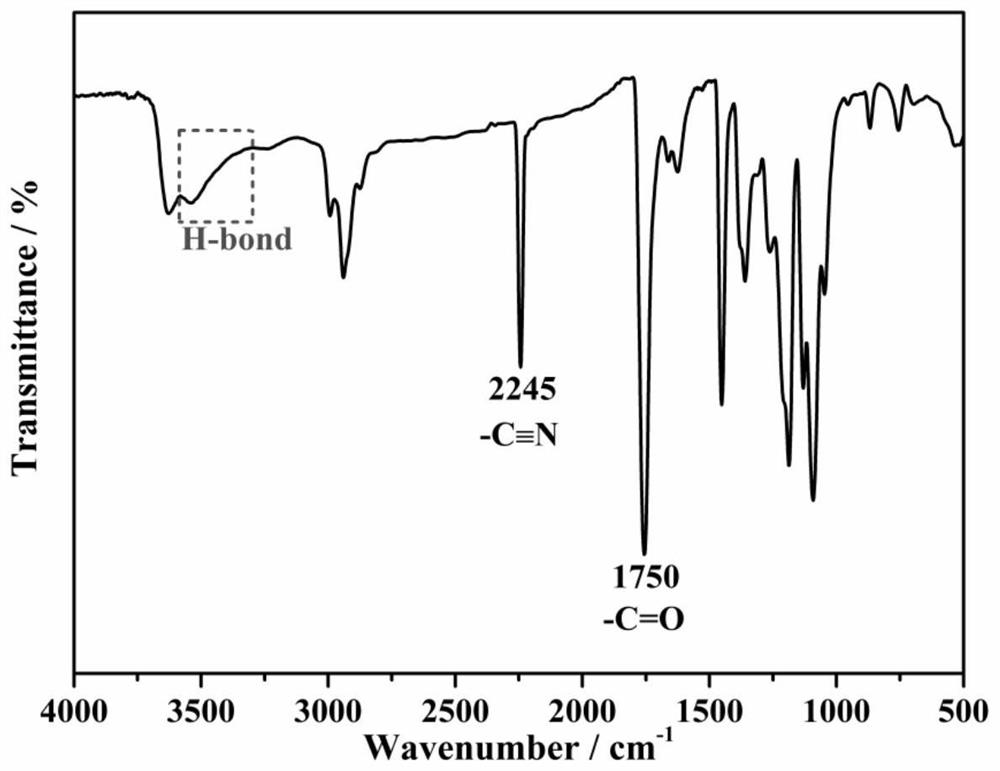

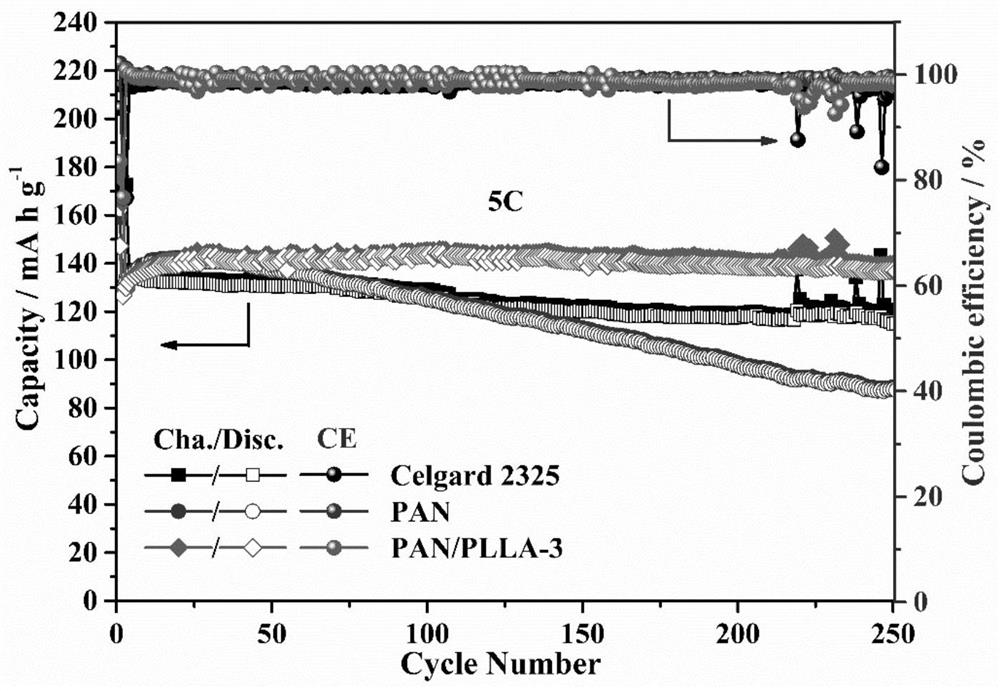

A gel-based and polymer-based technology, applied in the field of bio-based gel polymer electrolytes and their preparation, can solve the problem of affecting the electrochemical stability and safety of batteries, ionic conductivity that cannot meet application requirements, and polymer membrane pore distribution Inhomogeneity and other problems, to achieve the effect of good industrialization prospects, strong practicability, and good amorphousness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of this PAN / PLLA bio-based gel polymer electrolyte provided by the invention comprises the following steps:

[0036] (1) Weigh a certain amount of PAN powder and add it to 10ml N,N-dimethylformamide solvent, stir at 50°C and 700r / min until completely dissolved, and obtain C PAN =0.08g / mL light yellow transparent solution;

[0037] (2) press m PAN :m PLLA =3:1 mass ratio Weigh the PLLA powder and add it to the PAN solution obtained in step (1), stir at 50°C and 700r / min until completely dissolved, then continue stirring under this condition for 12h;

[0038] (3) Add the PAN / PLLA blended homogeneous solution obtained in step (2) into a 10ml syringe, inject under the conditions of low voltage -0.1kV and high voltage 15kV, and the injection speed is under the condition of 0.065mm / min The electrospinning electrospinning time is 10h;

[0039] (4) Put the PAN / PLLA blended polymer skeleton membrane obtained in step (3) into a vacuum drying oven for 12...

Embodiment 2

[0044] The preparation method of this PAN / PLLA bio-based gel polymer electrolyte provided by the invention comprises the following steps:

[0045] (1) Weigh a certain amount of PAN powder and add it to 10ml N,N-dimethylformamide solvent, stir at 50°C and 700r / min until completely dissolved, and obtain C PAN =0.08g / mL light yellow transparent solution;

[0046] (2) press m PAN :m PLLA =7:1 mass ratio Weigh the PLLA powder and add it to the PAN solution obtained in step (1), stir at 50°C and 700r / min until completely dissolved, then continue stirring under this condition for 12h;

[0047] (3) Add the PAN / PLLA blended homogeneous solution obtained in step (2) into a 10ml syringe, inject under the conditions of low voltage -0.1kV and high voltage 15kV, and the injection speed is under the condition of 0.007mm / min Carry out electrospinning, electrospinning time is 11h;

[0048] (4) Put the PAN / PLLA blended polymer skeleton film obtained in step (3) into a vacuum drying oven for...

Embodiment 3

[0052] The preparation method of this PAN / PLLA bio-based gel polymer electrolyte provided by the invention comprises the following steps:

[0053] (1) Weigh a certain amount of PAN powder and add it to 10ml N,N-dimethylformamide solvent, stir at 50°C and 700r / min until completely dissolved, and obtain C PAN =0.10g / mL light yellow transparent solution;

[0054] (2) press m PAN :m PLLA =5:1 mass ratio Weigh the PLLA powder and add it to the PAN solution obtained in step (1), stir at 50°C and 700r / min until completely dissolved, then continue stirring under this condition for 12h;

[0055] (3) Add the PAN / PLLA blended homogeneous solution obtained in step (2) into a 10ml syringe, inject under the conditions of low voltage -0.1kV and high voltage 15kV, and the injection speed is under the condition of 0.007mm / min Electrospinning is carried out; the electrospinning time is 12h;

[0056] (4) Put the PAN / PLLA blended polymer skeleton membrane obtained in step (3) into a vacuum dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com