Die and method for preparing polymer composite solid electrolyte through electric field induced orientation

A solid electrolyte and electric field induction technology, which is applied in the direction of composite electrolyte, electrolyte battery manufacturing, non-aqueous electrolyte battery, etc., to achieve strong selectivity, improve ionic conductivity, good elasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

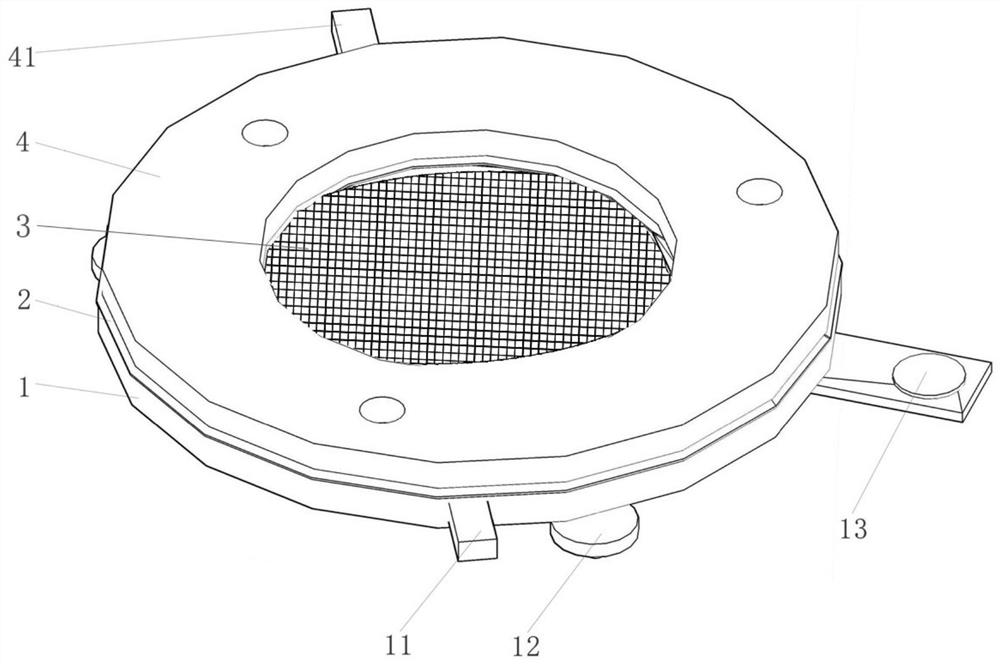

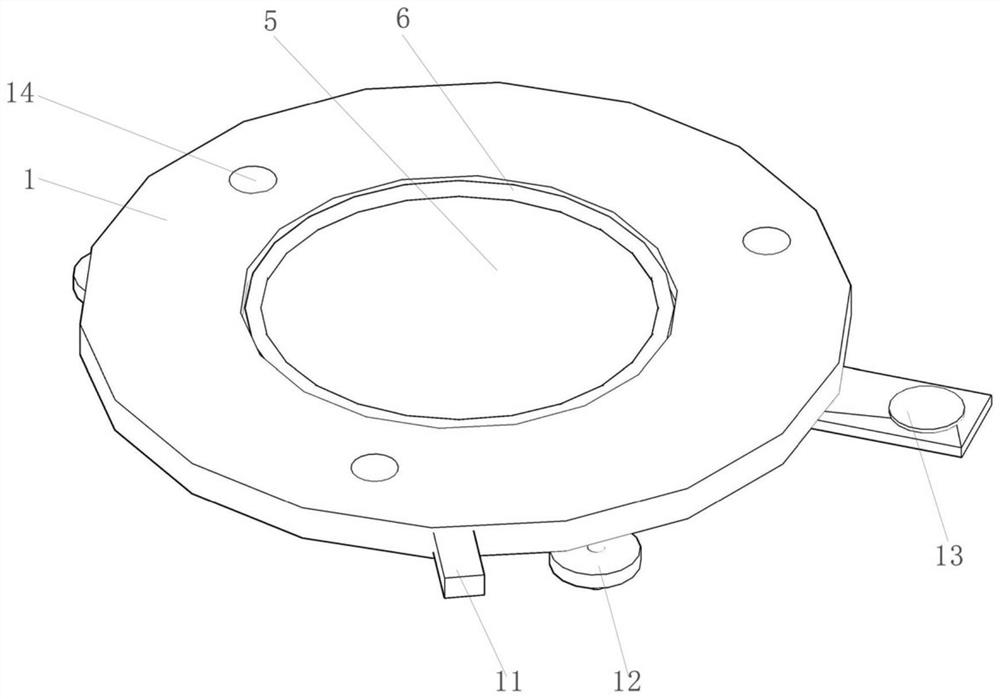

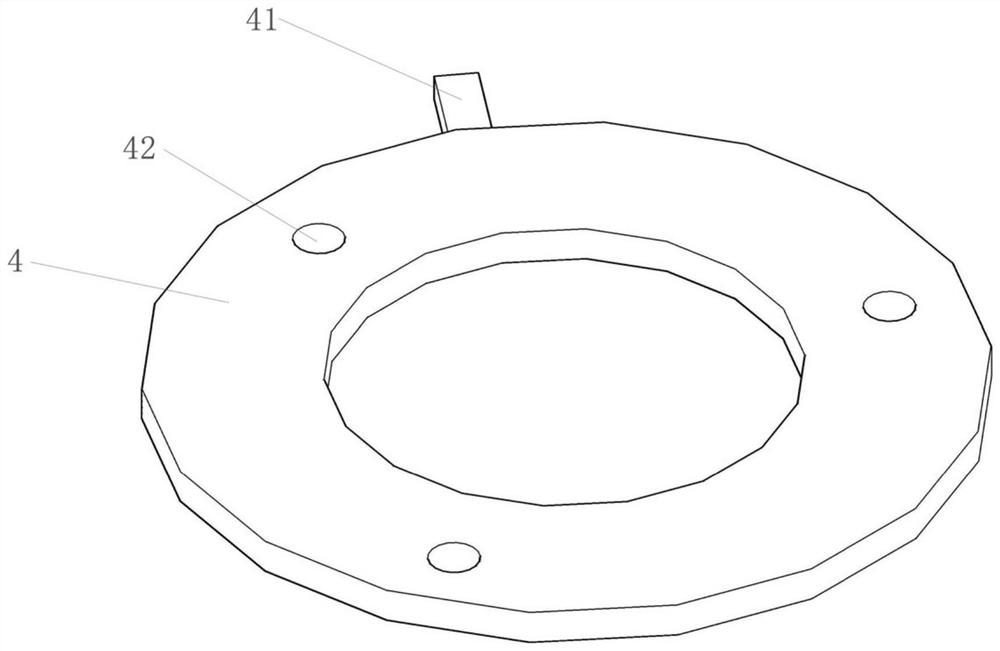

Image

Examples

Embodiment 1

[0055] In this example, the polymer PEO (molecular weight: 300,000) is used as the matrix, and the lithium salt LiClO is uniformly doped in the PEO 4 and inorganic material particles Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 , all carried out in a glove box full of an inert atmosphere, including the following steps:

[0056] a. In a glove box filled with an inert atmosphere, according to Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 , PEO and LiClO 4 The mass ratio of the salt is the ratio of 1.67:1:0.67, the PEO is dissolved with the solvent acetonitrile, and then LiClO is added 4 and Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 , and mechanically stirred and mixed to make a mixture, in which Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 The mass content of the mixture is 50%; then continue to add solvent acetonitrile to the mixture and stir for 8h, after mixing evenly, obtain a uniform mixed slurry, which is ready for degassing;

[0057] b. Pour the mixed slurry obtained in the step a into the circular tank,...

Embodiment 2

[0061] This embodiment is basically the same as Embodiment 1, and the special features are:

[0062] In this example, polyacrylonitrile PAN is used as a matrix, and lithium salt LiTFSI and inorganic material particles Li are uniformly doped in PAN. 14 Zn(GeO 4 ), all carried out in a glove box full of an inert atmosphere, including the following steps:

[0063] a. In a glove box filled with an inert atmosphere, according to Li 14 Zn(GeO 4 ) and the mass ratio of PAN and LiTFSI salt is the ratio of 0.6:1:0.4, adopt solvent N-methylpyrrolidone to dissolve PAN, then add LiTFSI and Li 14 Zn(GeO 4 ), mechanically stirred and mixed to make a mixture, wherein Li 14 Zn(GeO 4 ) with a mass content of 30%; then continue to add solvent N-methylpyrrolidone to the mixed slurry and stir for 8 hours, after mixing evenly, obtain a uniform mixed slurry, which is degassed for subsequent use;

[0064] b. Pour the mixed slurry obtained in the step a into the circular tank, adjust the mixed...

Embodiment 3

[0068] This embodiment is basically the same as Embodiment 1, and the special features are:

[0069] In this example, polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) was used as a matrix, and PVDF-HFP was uniformly doped with sodium salt (NaTFS) and inorganic material particles Li 0.33 La 0.557 TiO 3 , all carried out in a glove box full of an inert atmosphere, including the following steps:

[0070] a. In a glove box filled with an inert atmosphere, according to Li 0.33 La 0.557 TiO 3 The mass ratio of PVDF-HFP and NaTFS is 1.2:1:0.8, using a mixed solvent of N,N-dimethylformamide and acetone to dissolve PVDF-HFP, and then adding NaTFS and Li 0.33 La 0.557 TiO 3 , and mechanically stirred and mixed to make a mixture, in which Li 0.33 La 0.557 TiO 3 The mass content is 40%; then continue to add the mixed solvent of N,N-dimethylformamide and acetone to the mixed slurry, stir for 8 hours, and obtain a uniform mixed slurry after mixing evenly, which is degassed f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com