Eutectic solvent etched lithium cobalt oxide catalyst as well as preparation method and application thereof

A technology of deep eutectic solvent and lithium cobaltate, applied in the field of water treatment, can solve the problems of high raw material cost, serious secondary pollution, complex synthesis process, etc., achieve small secondary pollution, good catalytic effect, and simple etching process safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

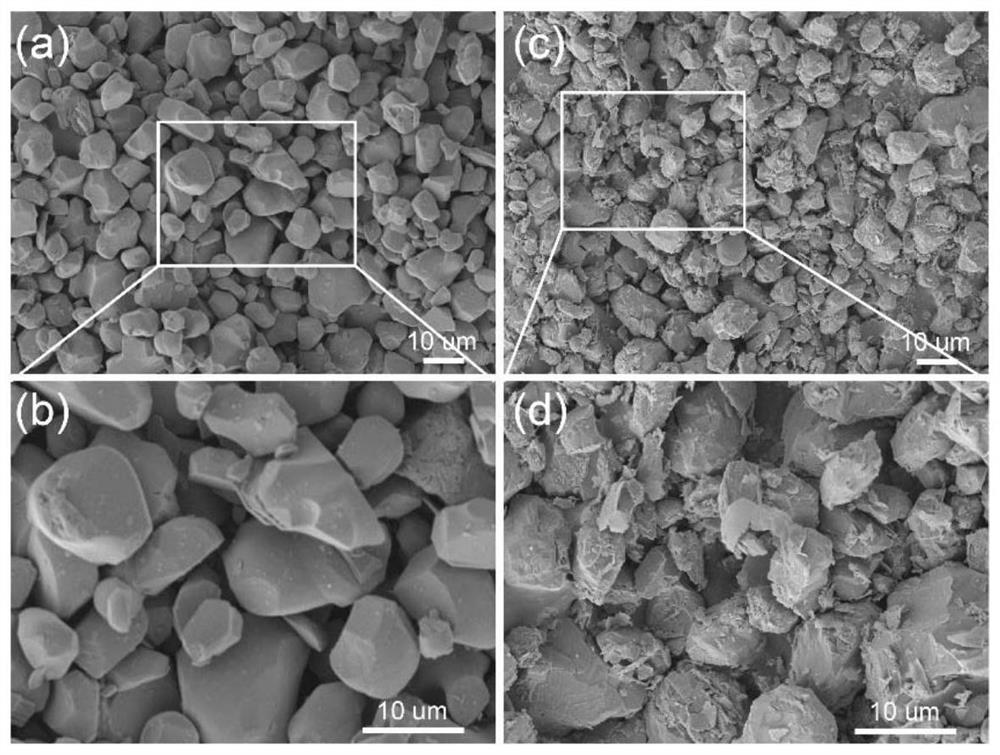

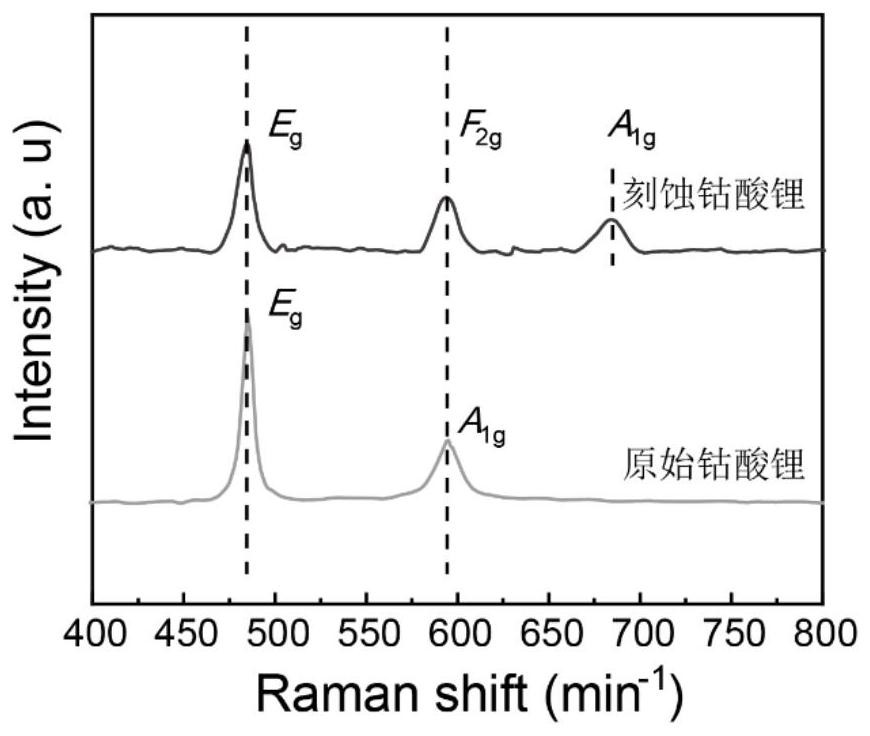

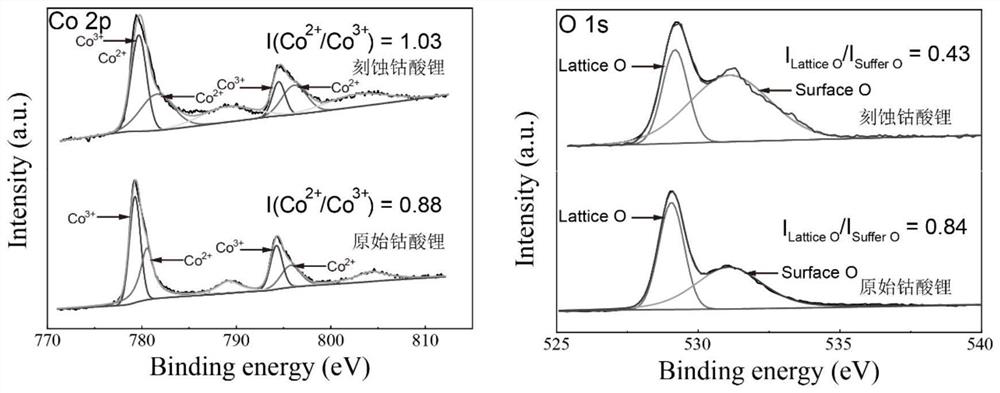

[0031] A kind of deep eutectic solvent etching lithium cobalt oxide catalyst

[0032] The preparation method of the deep eutectic solvent etching lithium cobalt oxide catalyst provided in this embodiment comprises the following steps:

[0033] (1) After mixing choline chloride and ethylene glycol at a molar ratio of 1:2, stir continuously at 60°C until clear and transparent, prepare a deep eutectic solvent and store it at 60°C;

[0034] (2) Mix lithium cobaltate and deep eutectic solvent into a high-temperature glass bottle according to a solid-to-liquid ratio of 20g / L, and keep the glass bottle in an oil bath for 4 hours at a temperature of 180°C;

[0035] (3) The lithium cobalt oxide and the deep eutectic solvent after etching are separated by suction filtration, and the solid product is washed alternately with alcohol and water several times to remove the deep eutectic solvent remaining on the solid surface, and a low eutectic solvent is obtained. Eutectic solvent etching ...

Embodiment 2

[0044] The preparation method of the deep eutectic solvent etching lithium cobalt oxide catalyst provided in this embodiment comprises the following steps:

[0045] (1) Choline chloride and ethylene glycol were mixed at a molar ratio of 1:2 and stirred continuously at 60°C until clear and transparent, and the deep eutectic solvent was prepared and stored at 60°C.

[0046](2) Mix lithium cobaltate and deep eutectic solvent into a high-temperature glass bottle according to a solid-to-liquid ratio of 30g / L, and keep the glass bottle in an oil bath for 6 hours at a temperature of 200°C.

[0047] (3) Use 6000 ram / min centrifugation to separate the lithium cobaltate and deep eutectic solvent after etching, and wash the precipitate with alcohol and water alternately several times to remove the deep eutectic solvent remaining on the solid surface, which is the obtained catalyst.

[0048] The deep eutectic solvent etching lithium cobaltate catalyst that embodiment 2 makes is carried o...

Embodiment 3

[0052] The preparation method of the deep eutectic solvent etching lithium cobalt oxide catalyst provided in this embodiment comprises the following steps:

[0053] (1) Choline chloride and ethylene glycol were mixed at a molar ratio of 1:2 and stirred continuously at 70°C until clear and transparent, and the deep eutectic solvent was prepared and stored at 60°C.

[0054] (2) Mix lithium cobaltate and deep eutectic solvent into a high-temperature glass bottle according to a solid-to-liquid ratio of 20g / L, and keep the glass bottle in an oil bath for 6 hours at a temperature of 180°C.

[0055] (3) Use suction filtration to separate the etched lithium cobaltate and the deep eutectic solvent, and alternately wash the lithium cobaltate several times with alcohol and water to remove the deep eutectic solvent remaining on the solid surface, which is the obtained catalyst.

[0056] The deep eutectic solvent etching lithium cobaltate catalyst that embodiment 3 is made carries out per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com