Purification method and purification device of 3, 4-dichloronitrobenzene

A technology of dichloronitrobenzene and a purification method, which is applied in the field of purification methods and purification devices of 3,4-dichloronitrobenzene, can solve the problem of high process risk of solvent method, difficulty in realizing automation, large number of theoretical trays, etc. problem, to achieve the effect of being conducive to continuous automatic production, high production efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

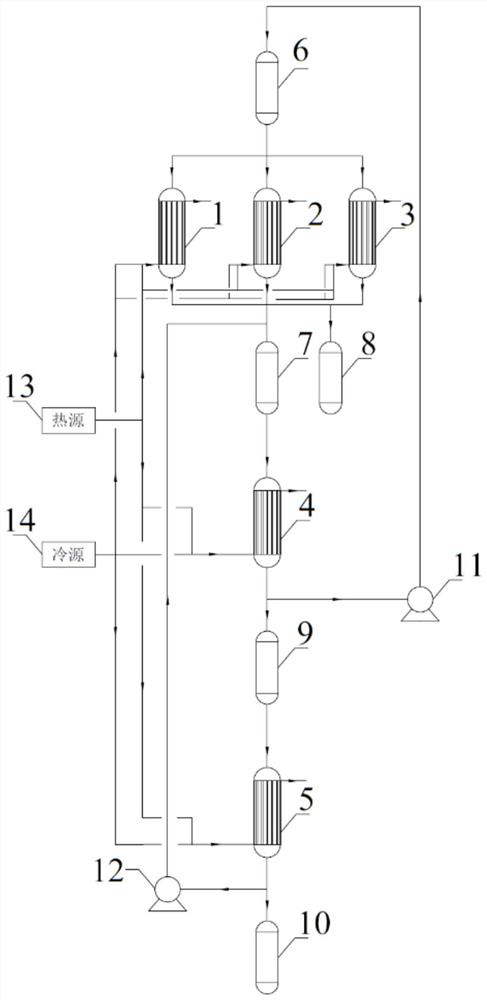

[0099] (a) Nitrification step: add mixed acid (98wt% nitric acid, 98wt% sulfuric acid mass ratio is 1:3) dropwise to o-dichlorobenzene at 20°C, keep warm at 60°C to the end, remove the acid water layer in layers, and then add 1500kg of 1% sodium bicarbonate solution, the temperature is 55 ℃, and the water layer is removed by layering to obtain 624kg of nitration product with a purity of 92.59%, which is put into the primary raw material storage tank 6.

[0100] (b) Primary melting and crystallization step: put the nitration product prepared in (a) into three primary melting crystallization kettles 1, 2, and 3 successively at 55° C., each 200 kg, pass through the cold source medium 14 and then cool down to 26 Crystallize at ℃ for 3.5 hours to obtain a primary crystallization product; open the perspiration valve, pass through the heat source medium 13, make the primary crystallization product melt and sweat again, control the heating rate at 3°C / hour, stop heating at 32°C and kee...

Embodiment 2

[0108] (a) Nitrification step: add mixed acid (98wt% nitric acid, 98wt% sulfuric acid mass ratio is 1:3) dropwise to o-dichlorobenzene at 20°C, keep warm at 60°C to the end, remove the acid water layer in layers, and then add 1500kg of 1% baking soda solution, the temperature is 55 ℃, and the water layer is removed by layering to obtain 619kg of nitration product with a purity of 92.38%, which is put into the primary raw material storage tank 6.

[0109] (b) Primary melting and crystallization step: put the primary raw material into three primary melting and crystallization kettles 1, 2, and 3 in sequence of 200 kg each at 60° C., cool to 27° C. and crystallize for 4 hours after passing through the cold source medium 14, Obtain the primary crystallization product; open the perspiration valve, pass into the heat source medium 13, make the primary crystallization product melt and sweat again, control the heating rate at 2.5°C / hour, stop heating at 32°C and keep it warm for 1 hour...

Embodiment 3

[0114] (a) Nitrification step: add mixed acid (98wt% nitric acid, 98wt% sulfuric acid mass ratio is 1:3) dropwise to o-dichlorobenzene at 20°C, keep warm at 60°C to the end, remove the acid water layer in layers, and then add 1500kg of 1% sodium bicarbonate solution, the temperature is 55 ℃, and the water layer is removed by layering to obtain 622kg of nitration product with a purity of 92.56%, which is put into the primary raw material storage tank 6.

[0115] (b) Primary melting and crystallization step: put the primary raw material into three primary melting and crystallization kettles 1, 2, and 3 in sequence of 200 kg each at 60° C., cool down to 28° C. and crystallize for 4.5 hours after passing through the cold source medium 14, Obtain the primary crystalline product; open the perspiration valve, pass through the heat source medium 13, make the primary crystalline product melt and sweat again, control the heating rate at 2°C / hour, stop heating at 33°C and keep it warm for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com