A kind of high-toughness waterborne acrylic paint and preparation method thereof

A water-based acrylic, high-toughness technology, applied in the field of coatings, can solve the problems of long drying time for resin film formation, thermal stickiness and brittleness of paint film, short service life, etc., to improve toughness and mechanical properties, prolong service life, disperse The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

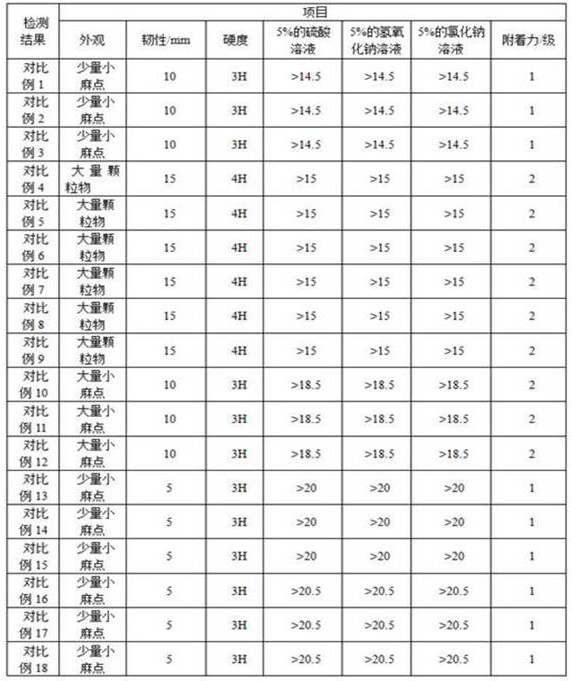

Examples

Embodiment 1

[0030] Weigh 2g of microcrystalline cellulose and 45mL of sulfuric acid solution with a mass fraction of 64%, place them in a conical flask and stir to disperse to obtain a dispersion solution, heat up to 40°C and keep for 2h to take out the precipitate, add 30mL to the precipitate to remove After deionized water, centrifuge at a speed of 3000r / min for 3min, centrifuge repeatedly 3 times to separate the solid centrifuged product, put the solid centrifuged product into a dialysis bag and dialyze to pH=7, and then obtain the dialysis product; Homogeneous treatment under homogeneous pressure, the number of cycles is 5 times to obtain cellulose nano colloid.

[0031] Add 80g of cellulose nanocolloid, 25mL of absolute ethanol and 70mL of ethyl orthosilicate into a three-necked flask in sequence, stir and disperse to obtain a dispersion; heat the dispersion to 60°C, keep it warm and stir for 2 hours, then add a molar ratio of 20% After adjusting the pH to 9 with ammonia water, heat ...

Embodiment 2

[0037] Weigh 5g of microcrystalline cellulose and 49mL of sulfuric acid solution with a mass fraction of 64%, place them in a conical flask and stir to disperse to obtain a dispersion, heat up to 45°C and keep for 3h to take out the precipitate, add 40mL to the precipitate to remove After deionized water, centrifuge at a speed of 4000r / min for 5min, centrifuge repeatedly 3 times to separate the solid centrifuged product, put the solid centrifuged product into a dialysis bag and dialyze to pH=7, and then obtain the dialysis product; Homogeneous treatment under homogeneous pressure, the number of cycles is 5 times to obtain cellulose nano colloid.

[0038] Add 96g of cellulose nano-colloid, 27mL of absolute ethanol and 82mL of ethyl orthosilicate into a three-necked flask in turn, stir and disperse to obtain a dispersion; heat the dispersion to 65°C and keep stirring for 3 hours, then add a molar ratio of 20% After adjusting the pH to 9 with ammonia water, heat up to 80°C and co...

Embodiment 3

[0044] Weigh 10g of microcrystalline cellulose and 55mL of sulfuric acid solution with a mass fraction of 64%, place them in a conical flask and stir to disperse to obtain a dispersion, heat up to 50°C and keep for 2h to take out the precipitate, add 50mL to the precipitate to remove After deionized water, centrifuge at a speed of 5000r / min for 5min, repeat centrifugation for 3 times to separate the solid centrifuged product, put the solid centrifuged product into a dialysis bag and dialyze to pH=7, and then obtain the dialysis product; Homogeneous treatment under homogeneous pressure, the number of cycles is 5 times to obtain cellulose nano colloid.

[0045] Add 100g of cellulose nanocolloid, 30mL of absolute ethanol and 90mL of ethyl orthosilicate into a three-necked flask in turn, stir and disperse to obtain a dispersion; heat the dispersion to 70°C and keep it for 4 hours, then add a molar ratio of 20% After adjusting the pH to 9 with ammonia water, heat up to 90°C and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com