Soapstock oil foot acidification reaction system and process

A reaction system and oil foot technology are applied in the acidification reaction system and process field of soap foot oil foot, which can solve the problems of solid waste pollution, pollution, environmental problems, etc., so as to reduce economic burden and sewage, save energy investment, reduce The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

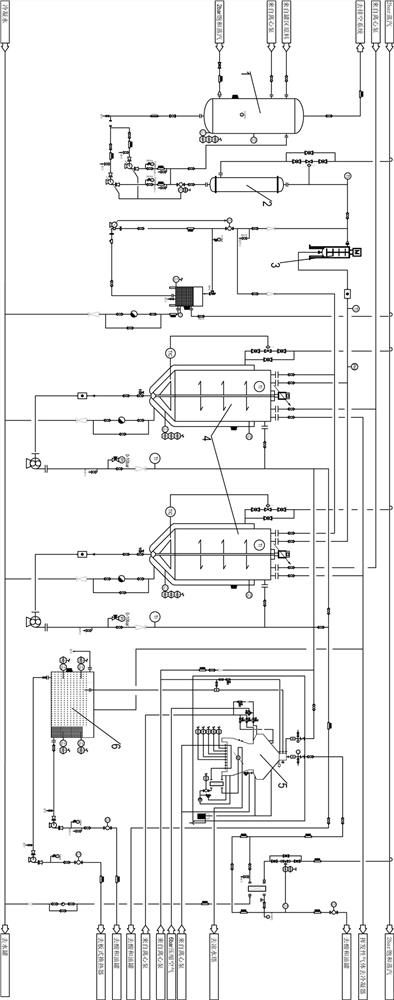

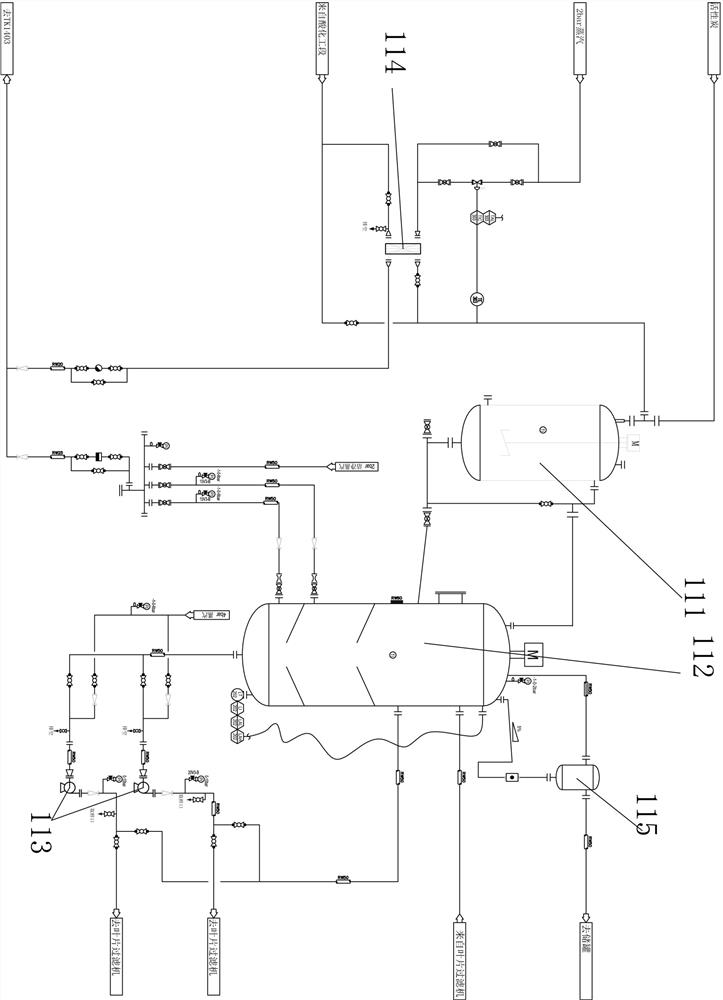

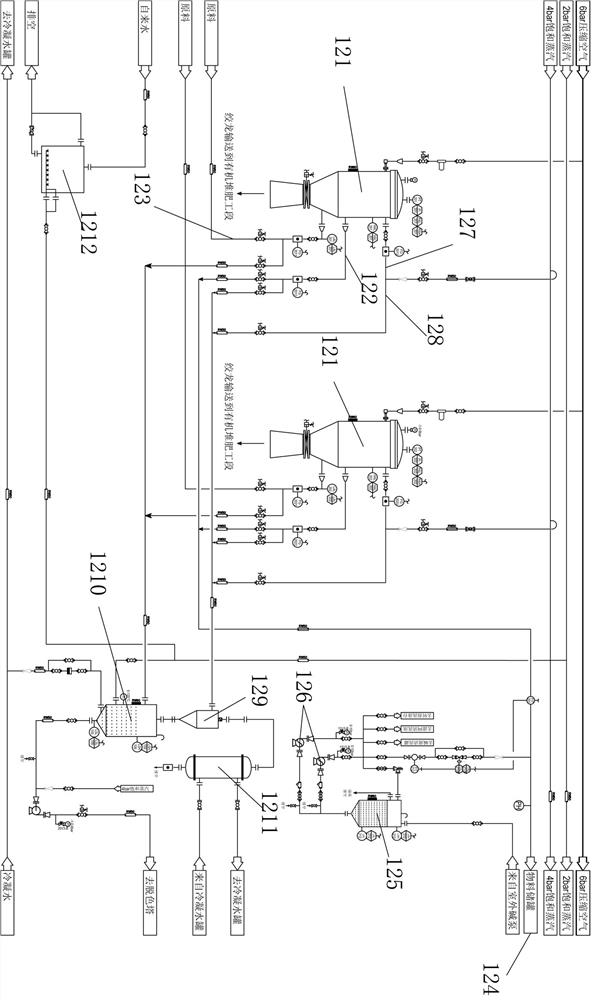

[0029] As shown in the figure, a soapstock acidification reaction system includes a buffer tank 1 for preheating the raw materials, the outlet pipeline of the buffer tank 1 is communicated with the inlet of the heater 2, and the soapstock after being heated by the heater 1 The oil foot is sent into the mixer 3 and the acetic acid from the acetic acid tank 7 is mixed in the mixer and then sent to the reaction tank 4 for reaction, the reactant from the reaction tank 4 enters the intermediate tank for cooling, and the intermediate tank sends the reactant to the centrifugal separation After the separation of the device 6, it is divided into two parts, one part is sodium acetate and is sent to the recovery processing system for further recycling, and the other part is the mixture of fatty acid and oil, which is sent into the separation system for further separation, and the centrifugal separator 5 is also provided with an oil-water separation tank 6 , the oil-water separation box 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com