A lithium ion battery and its preparation process

A lithium-ion battery and preparation technology, applied in the field of phosphorene composite graphite lithium-ion battery and its preparation, can solve the problems of poor mechanical stress, low electrochemical performance, poor thermal stability, etc., to improve charge and discharge performance, improve Rate performance, effect of reducing diffusion internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

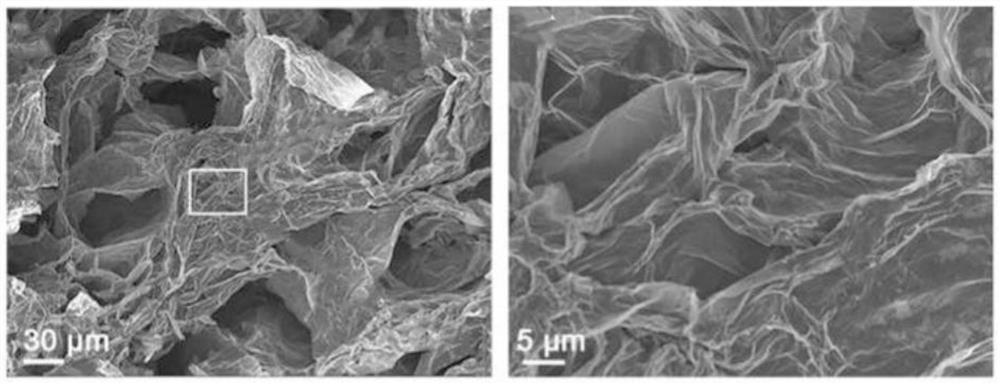

Image

Examples

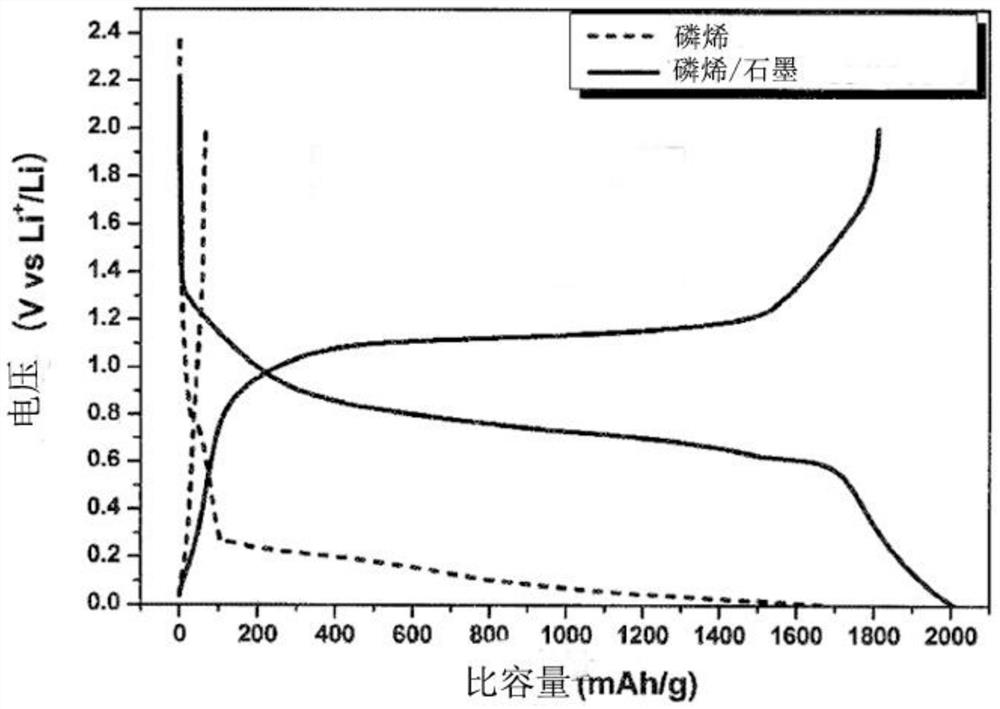

Embodiment 1

[0031] 1) Add 0.1 part of graphite microparticles to 0.5 mol / l, 10 L ammonium borate aqueous solution, stir for 12 hours, and freeze-dry.

[0032] 2) Encapsulate the mixture of phosphorene and graphite in step 1) with 10 parts and 90 parts respectively in a silver tube (inner diameter: 4.90 mm).

[0033] 3) The silver tube was placed in a hydrothermal system (model HR-1B-2, LECO Tem-Pres) and heated at 300-550° C. and 0.1-0.4 GPa for 1 hour.

[0034] 4) The pressure in the autoclave was quenched immediately by releasing the pressure valve, and the autoclave was naturally cooled to room temperature to obtain a black compound.

[0035] 5) Add 10 parts by weight of acetylene black and 10 parts by weight of binder to the product of step 4), grind and coat the surface of the copper foil current collector, dry, card, and press to obtain the negative electrode material electrode sheet.

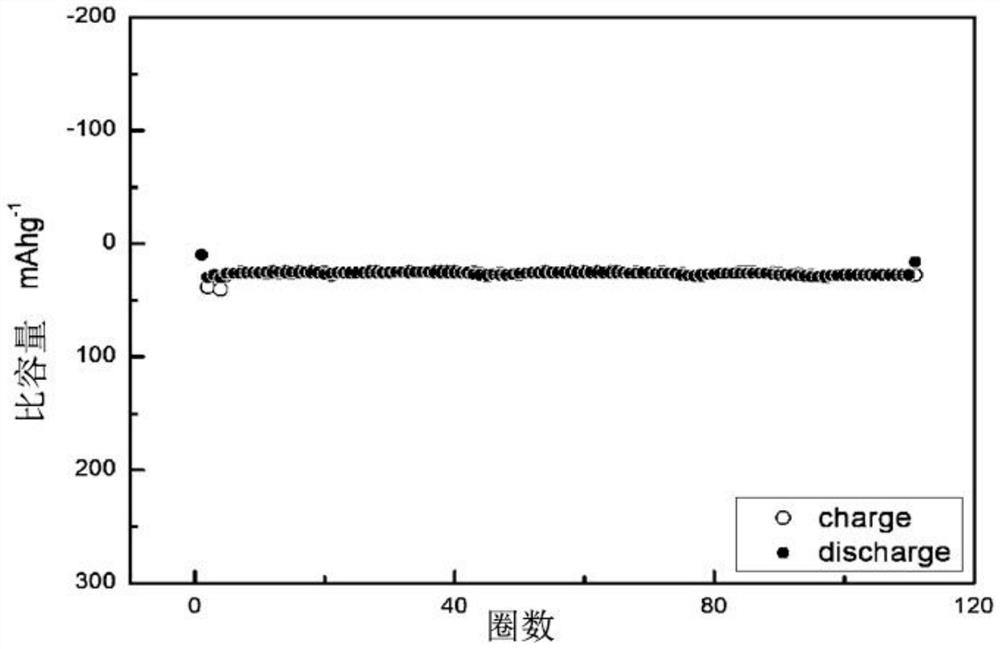

[0036] 6) Put the electrode sheet, diaphragm, LB-008 electrolyte with crown ether grafted chitos...

Embodiment 2

[0039] 1) Add 0.1 part of graphite microparticles to 0.5 mol / l, 10 L ammonium borate aqueous solution, stir for 12 hours, and freeze-dry.

[0040] 2) Encapsulate the mixture of phosphorene and graphite in step 1) with 15 parts and 85 parts respectively in a silver tube (inner diameter 4.90mm).

[0041] 3) The silver tube was placed in a hydrothermal system (model HR-1B-2, LECO Tem-Pres) and heated at 300-550° C. and 0.1-0.4 GPa for 1 hour.

[0042] 4) The pressure in the autoclave was quenched immediately by releasing the pressure valve, and the autoclave was naturally cooled to room temperature to obtain a black compound.

[0043] 5) Add 10 parts by weight of acetylene black and 10 parts by weight of binder to the product of step 4), grind and coat the surface of the copper foil current collector, dry, card, and press to obtain the negative electrode material electrode sheet.

[0044] 6) Put the electrode sheet, diaphragm, LB-008 electrolyte with crown ether grafted chitosan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com