Preparation method of hydrophobic antibacterial ceramic membrane

A technology of antibacterial ceramics and ceramic membranes, applied in the field of ceramic membranes, can solve the problems of reducing the water flux and water treatment effect of ceramic membranes, shortening the service life, and endangering the health of consumers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

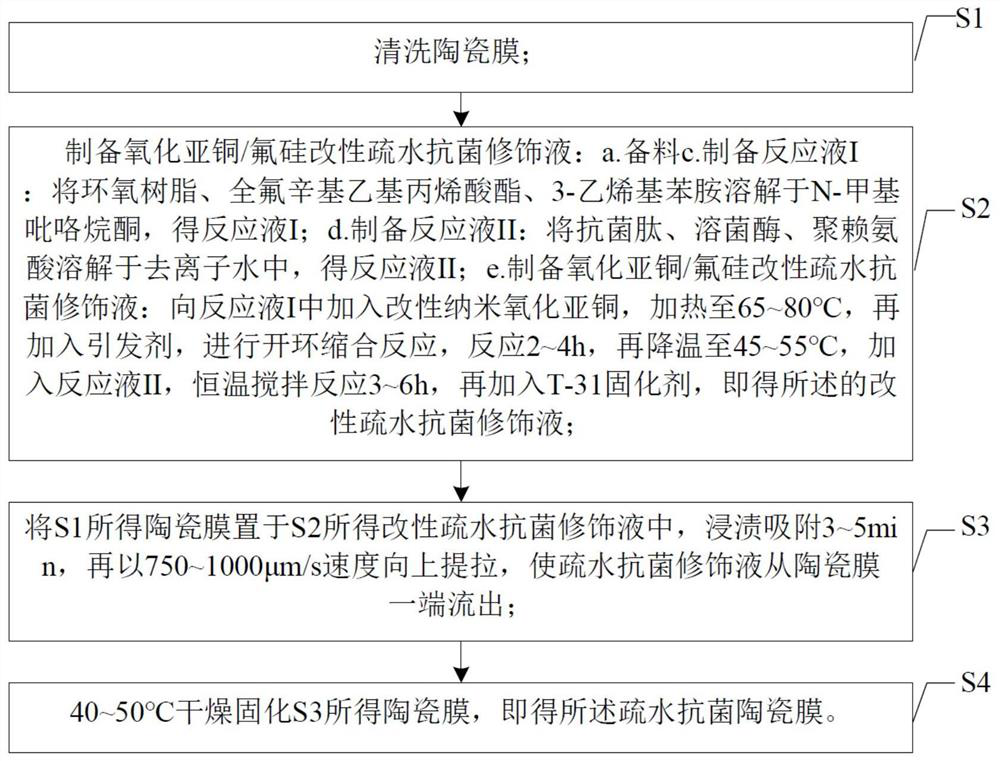

[0030] A method for preparing a hydrophobic antibacterial ceramic film, comprising the following steps:

[0031] S1: Clean the ceramic membrane:

[0032] Immerse a ceramic membrane with a porosity of 40% and a pore size of 0.1 μm in a 0.1mol / L KOH solution, ultrasonically treat it for 10 minutes, and add a 0.2mol / L HCl solution dropwise to adjust the pH to 7.0;

[0033] Then immerse in a solution with a mass concentration of 0.1% sodium cocoyl glycinate, ultrasonically treat for 0.5h, and rinse with clean water;

[0034] S2: Preparation of cuprous oxide / fluorine silicon modified hydrophobic and antibacterial modification solution:

[0035] a. Material preparation: Weigh 30 parts of epoxy resin, 6 parts of perfluorooctyl ethyl acrylate, 4 parts of 3-vinylaniline, N-β-(aminoethyl)-γ-aminopropyl 3 parts of trimethoxysilane, 3 parts of nano-cuprous oxide with an average particle size of 2nm, 0.3 part of benzoyl peroxide, 1 part of antimicrobial peptide, 0.5 part of lysozyme, 0.5...

Embodiment 2

[0043] A method for preparing a hydrophobic antibacterial ceramic film, comprising the following steps:

[0044] S1: Clean the ceramic membrane:

[0045] Immerse a ceramic membrane with a porosity of 45% and a pore diameter of 0.5 μm in a 0.1mol / L KOH solution, ultrasonically treat it for 10 minutes, and add 0.4mol / L HCl solution dropwise to adjust the pH to 7.0;

[0046]Then immerse in a solution of sodium cocoyl glutamate with a mass concentration of 0.1%, ultrasonically treat for 0.5 to 1 hour, and rinse with water, then it is ready;

[0047] S2: Preparation of cuprous oxide / fluorine silicon modified hydrophobic and antibacterial modification solution:

[0048] a. Material preparation: Weigh 35 parts of epoxy resin, 9 parts of perfluorooctyl ethyl acrylate, 6 parts of 3-vinylaniline, N-β-(aminoethyl)-γ-aminopropyl 4 parts of trimethoxysilane, 4 parts of nano cuprous oxide with an average particle size of 4nm, 0.4 parts of lauroyl peroxide, 1.5 parts of antimicrobial pepti...

Embodiment 3

[0056] A method for preparing a hydrophobic antibacterial ceramic film, comprising the following steps:

[0057] S1: Clean the ceramic membrane:

[0058] Immerse a ceramic membrane with a porosity of 50% and a pore diameter of 0.5 μm in a 0.3mol / L KOH solution, ultrasonically treat it for 15 minutes, and add a 0.5mol / L HCl solution dropwise to adjust the pH to 7.0;

[0059] Then immerse in a solution with a mass concentration of 0.2% sodium lauroyl aspartate, ultrasonically treat for 1 hour, and rinse with water;

[0060] S2: Preparation of cuprous oxide / fluorine silicon modified hydrophobic and antibacterial modification solution:

[0061] a. Material preparation: Weigh 40 parts of epoxy resin, 12 parts of perfluorooctyl ethyl acrylate, 8 parts of 3-vinyl aniline, N-β-(aminoethyl)-γ-aminopropyl 5 parts of trimethoxysilane, 5 parts of nano-cuprous oxide with an average particle size of 6nm, 0.5 parts of azobisisobutyronitrile, 3 parts of antimicrobial peptides, 2 parts of ly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com