Metal organic framework forming body and preparation method and application thereof

A metal-organic framework and molding technology, applied in the field of metal-organic frameworks, can solve the problems of large loss of MOFs and low adsorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] In the present invention, the preparation method of the MOFs may be a preparation method conventionally used in the art, preferably, the preparation method of the MOFs comprises: mixing and reacting a metal salt and an organic ligand in the presence of a solvent I, Get MOFs.

[0058] In the present invention, the metal elements in the metal salt can be conventional metal elements used to prepare metal-organic framework moldings, preferably selected from Mg, Ca, Sr, Ba, Sc, Y, Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, W, Mn, Re, Fe, Ru, Os, Co, Rh, Ir, Ni, Pd, Pt, Cu, Ag, Au, Zn, Cd, Hg, Al, Ga, At least one of In, Tl, Si, Ge, Sn, Pb, As, Sb and Bi. The corresponding metal ion of the metal element is preferably: Mg 2+ , Ca 2+ 、Sr 2+ 、Ba 2+ 、Sc 3+ , Y 3+ 、Ti 4+ 、Zr 4+ 、Hf 4+ , V 4+ , V 3+ , V 2+ , Nb 3+ 、 Ta 3+ 、Cr 3+ 、Mo 3+ , W 3+ , Mn 3+ , Mn 2+ 、Re 3+ 、Re 2+ , Fe 3+ , Fe 2+ 、Ru 3+ 、Ru 2+ , Os 3+ , Os 2 + 、Co 3+ 、Co 2+ 、Rh 2+ 、Rh + 、Ir 2+ 、Ir + 、...

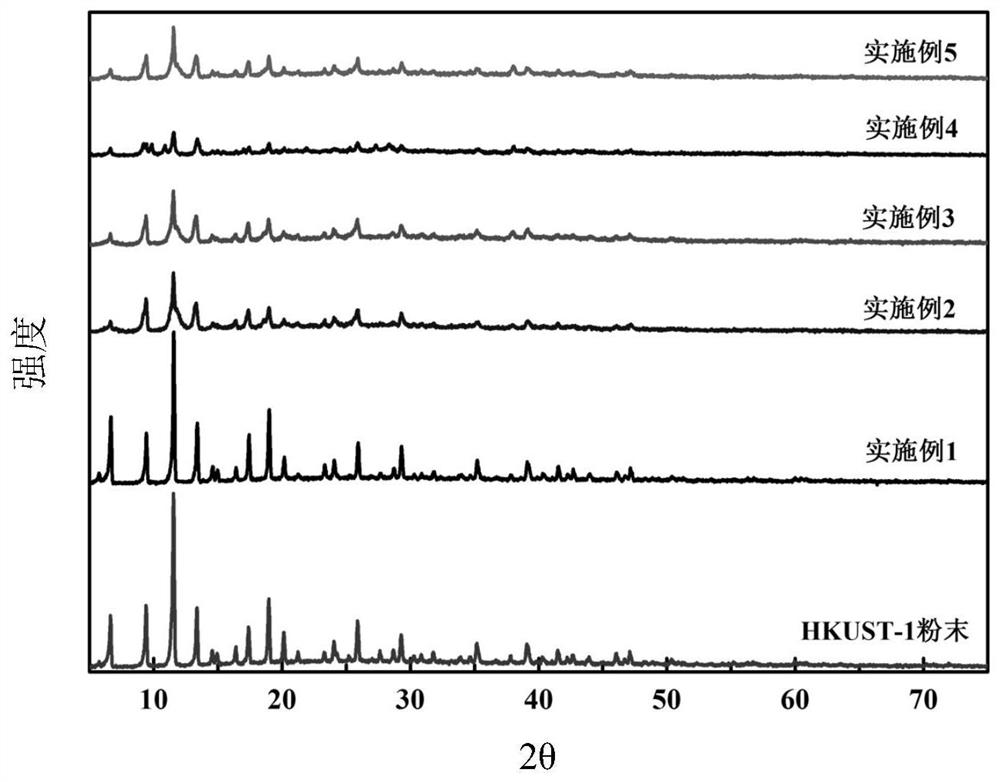

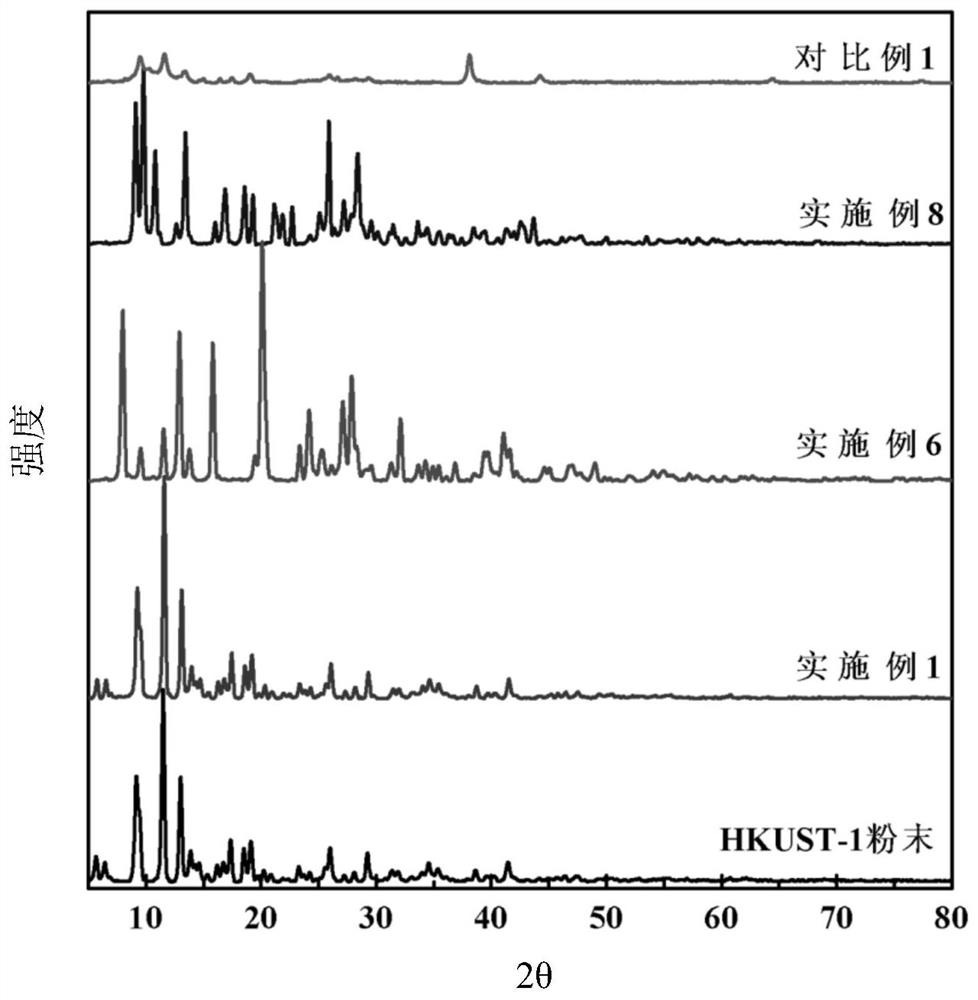

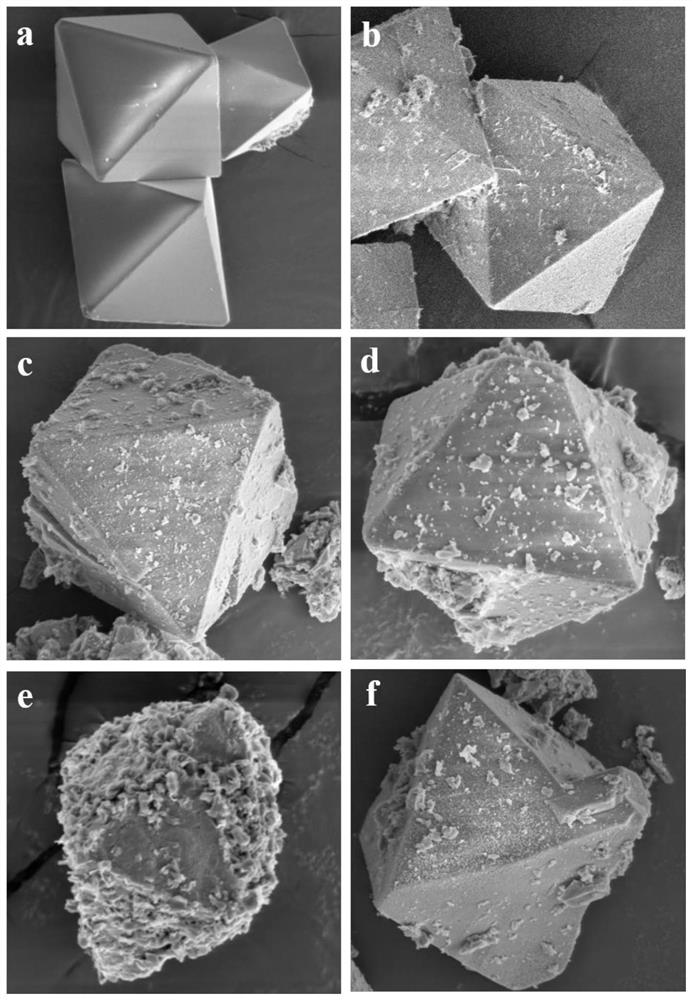

Embodiment 1

[0098] This example is used to illustrate the preparation method of the metal-organic framework molding of the present invention

[0099] (1) Add 6g of trimesic acid into a mixture of 250g of absolute ethanol and 100g of water, stir thoroughly for 20min, then add 11g of copper acetate and 50g of absolute ethanol, and stir thoroughly for 30min. After forming a gel, the above mixture was placed in an ultrasonic reaction for 10 min, and then continued to stir at room temperature for 16 h to obtain a uniform gel-like substance. The obtained product was centrifuged and washed 3 times with absolute ethanol, and dried at 60° C. for 10 h. After drying, HKUST-1 with a smaller crystal size was obtained, and then HKUST-1 was ground into powder.

[0100] (2) Weigh 3g of polyvinyl alcohol 2699 and mix it with 100g of deionized water at 90°C, stir and dissolve to obtain a PVA solution, and then mix it with HKUST-1 powder to form a gel. The mass of HKUST-1 and PVA solution The ratio is 4:1....

Embodiment 2

[0103] This example is used to illustrate the preparation method of the metal-organic framework molding of the present invention

[0104] (1) Add 11g of trimesic acid into a mixture of 250g of absolute ethanol and 100g of water, stir thoroughly for 20min, then add 11g of copper acetate and 50g of absolute ethanol, and stir thoroughly for 30min. After forming a gel, the above mixture was placed in an ultrasonic reaction for 10 min, and then continued to stir at room temperature for 16 h to obtain a uniform gel-like substance. The obtained product was centrifuged and washed 3 times with absolute ethanol, and dried at 60° C. for 10 h. After drying, HKUST-1 with a smaller crystal size was obtained, and then HKUST-1 was ground into powder.

[0105] (2) Weigh 3g of polyvinyl alcohol 2699 and mix it with 100g of deionized water at 90°C, stir and dissolve to obtain a PVA solution, and then mix it with HKUST-1 powder to form a gel. The mass of HKUST-1 and PVA solution The ratio is 4:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com