Anti-sticking coating and preparation method thereof

A technology of coatings and parts by weight, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of anti-sticking coatings losing their effect, poor coating durability, and repairing, etc., to achieve Excellent self-cleaning ability, good surface effect, anti-sticking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

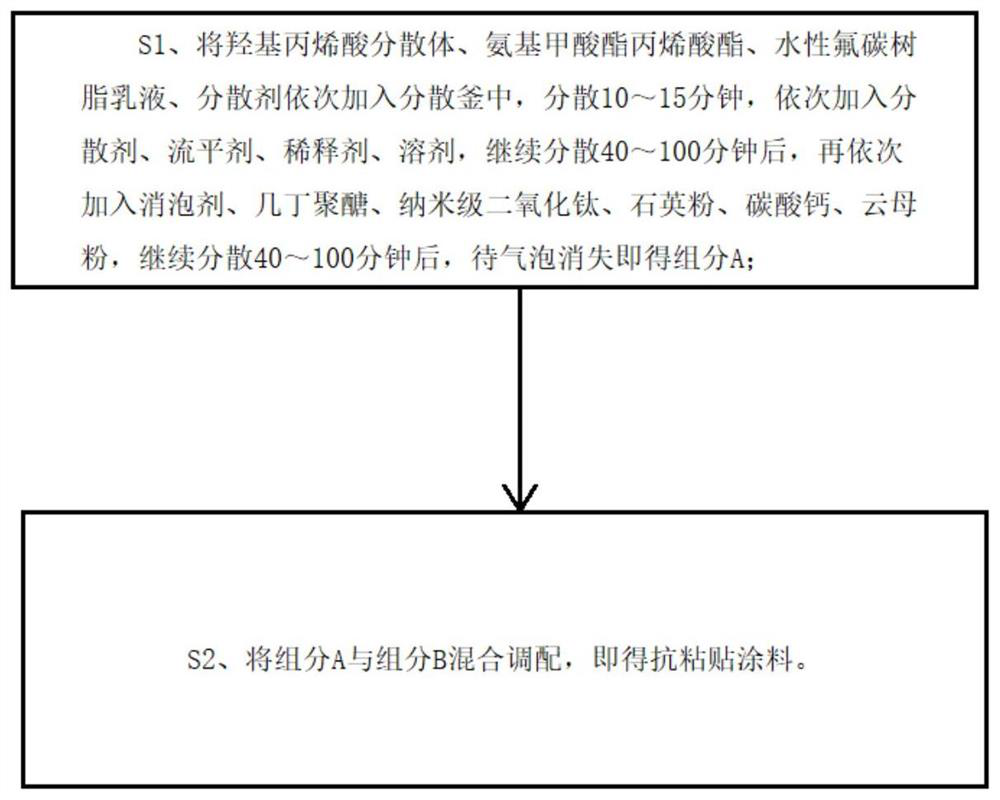

Method used

Image

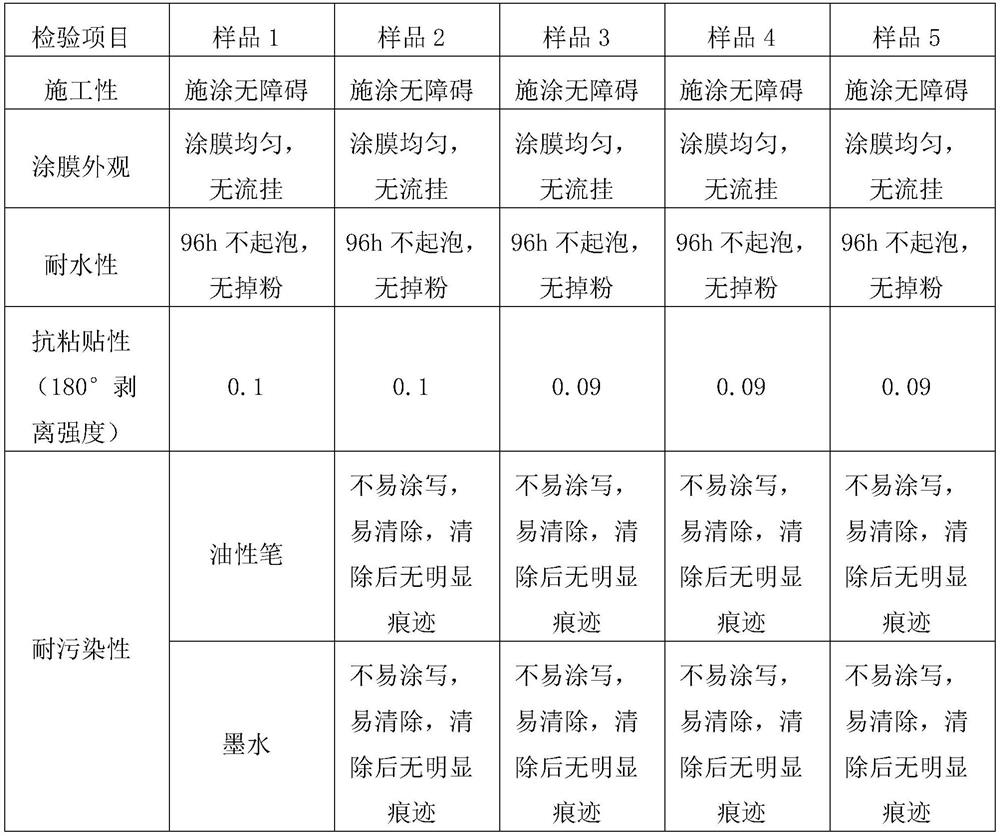

Examples

Embodiment 1

[0026] An anti-stick coating is characterized in that it includes A component and B component, and the A component includes the following components: 18g of hydroxyacrylic acid dispersion, 10g of urethane acrylate, 5g of water-based fluorocarbon resin emulsion, several Tetrasan 5g, nano-scale titanium dioxide 2g, quartz powder 7g, calcium carbonate 8g, mica powder 10g, dispersant 0.2g, leveling agent 0.3g, diluent 2g, defoamer 0.5g, solvent 4g; the B group Divided into a curing agent; the weight ratio of the component A to the component B is 4:1.

[0027] Wherein, the particle size of the nanoscale titanium dioxide is ≤300nm.

[0028] Wherein, the fluorine content in the aqueous fluorocarbon resin emulsion is greater than 10%.

[0029] Wherein, the leveling agent is a fluorocarbon modified polymer leveling agent, the defoamer is a water-based silicone defoamer, and the curing agent is an aliphatic polyisocyanate curing agent.

[0030] Wherein, the diluent is composed of the ...

Embodiment 2

[0035] An anti-stick coating is characterized in that it includes A component and B component, and the A component includes the following components: 35g of hydroxyacrylic acid dispersion, 20g of urethane acrylate, 14g of water-based fluorocarbon resin emulsion, several Tetracan 10g, nano-scale titanium dioxide 4g, quartz powder 18g, calcium carbonate 13g, mica powder 10g, dispersant 0.5g, leveling agent 1.5g, diluent 1.6g, defoamer 1g, solvent 5g; the B group Divided into a curing agent; the weight ratio of the component A to the component B is 4:1.

[0036] Wherein, the particle size of the nanoscale titanium dioxide is ≤300nm.

[0037] Wherein, the fluorine content in the aqueous fluorocarbon resin emulsion is greater than 10%.

[0038] Wherein, the leveling agent is a fluorocarbon modified polymer leveling agent, the defoamer is a water-based silicone defoamer, and the curing agent is an aliphatic polyisocyanate curing agent.

[0039] Wherein, the diluent is composed of ...

Embodiment 3

[0044] An anti-stick coating is characterized in that it includes A component and B component, and the A component includes the following components: 26g of hydroxyacrylic acid dispersion, 15g of urethane acrylate, 15g of water-based fluorocarbon resin emulsion, several Tetrasan 10g, nano-scale titanium dioxide 4g, quartz powder 10g, calcium carbonate 8g, mica powder 10g, dispersant 0.6g, leveling agent 0.5g, diluent 0.5g, defoamer 0.6g, solvent 5g; The component is a curing agent; the weight ratio of the component A to the component B is 4:1.

[0045] Wherein, the particle size of the nanoscale titanium dioxide is ≤300nm.

[0046]Wherein, the fluorine content in the aqueous fluorocarbon resin emulsion is greater than 10%.

[0047] Wherein, the leveling agent is a fluorocarbon modified polymer leveling agent, the defoamer is a water-based silicone defoamer, and the curing agent is an aliphatic polyisocyanate curing agent.

[0048] Wherein, the diluent is composed of the foll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com