Acrylic foamed damping foam and preparation method thereof

An acrylic and foam technology, used in film/sheet adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of thick material thickness, inability to bend, poor flexibility, etc. Achieve superior durability, flexible bending, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

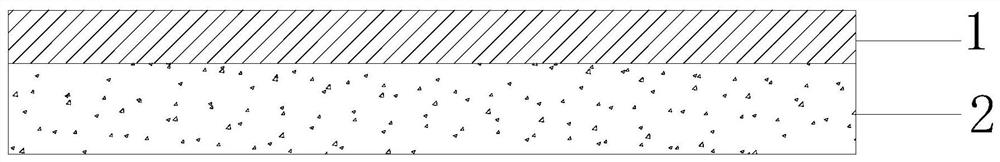

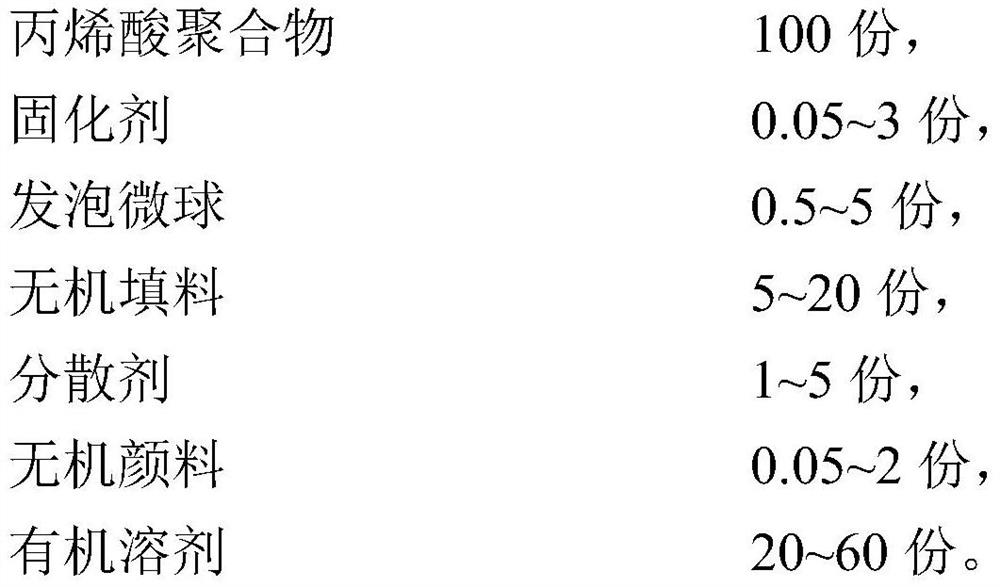

[0029] Embodiment 1: An acrylic foamed shock-absorbing foam, the acrylic foamed shock-absorbing foam is applied to an OLED module, including a release film layer 1 and an acrylic foam layer 2, and the release film layer 1 and the acrylic foam layer 2 are stacked together, and the acrylic foam layer 2 is formed by coating and drying an acrylic foam coating solution, and the acrylic foam coating solution is made of the following components in parts by weight become:

[0030]

[0031] A method for preparing a foam material, comprising the steps of:

[0032] In S1, firstly add 30 parts of ethyl acetate organic solvent and 1.5 parts of fatty acid dispersant, mix and stir evenly, then add 2 parts of foamed microspheres, 2 parts of inorganic filler silica, 0.5 parts of inorganic pigment carbon black, and mix at high speed disperse and stir;

[0033] S2 After the above step S1, add 100 parts of solvent-based acrylic polymer resin, and after fully grinding and dispersing, add 0.4 ...

Embodiment 2

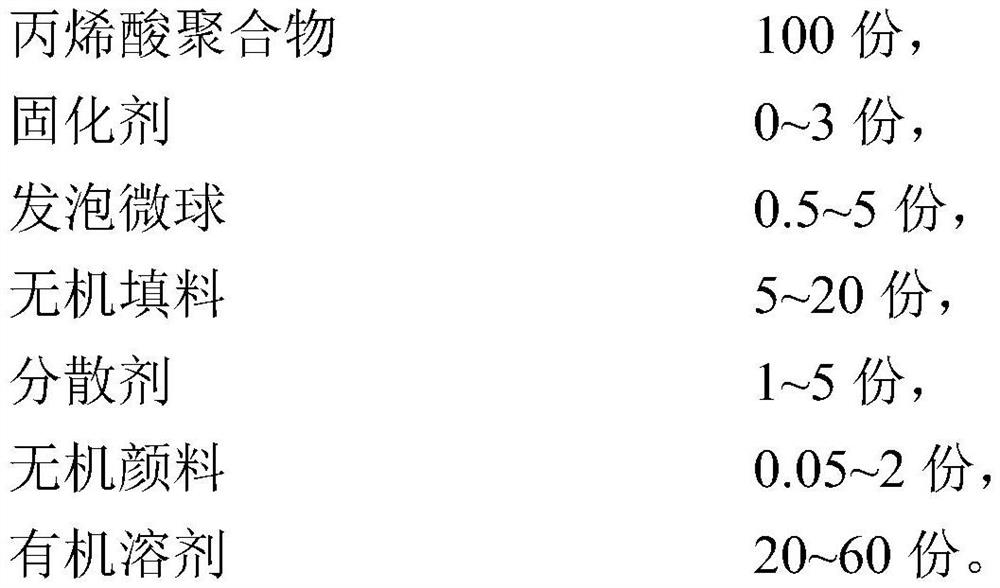

[0036] An acrylic foamed shock-absorbing foam, the acrylic foamed shock-absorbing foam applied to OLED modules, including a release film layer 1 and an acrylic foam layer 2, the release film layer 1 and acrylic foam Layers 2 are stacked together, and the acrylic foam layer 2 is formed by coating and drying an acrylic foam coating solution, and the acrylic foam coating solution is made of the following components in parts by weight:

[0037]

[0038] A method for preparing a foam material, comprising the steps of:

[0039]In S1, first add 40 parts of butyl acetate organic solvent and 2.2 parts of low-molecular wax dispersant, mix and stir evenly, then add 2 parts of foamed microspheres, 1 part of inorganic filler silica, 0.2 part of inorganic pigment carbon black, High-speed mixing and dispersing stirring;

[0040] S2 After the above step S1, add 100 parts of solvent-based acrylic polymer resin, and after fully grinding and dispersing, add 0.2 parts of isocyanate curing age...

Embodiment 3

[0043] An acrylic foamed shock-absorbing foam, the acrylic foamed shock-absorbing foam applied to OLED modules, including a release film layer 1 and an acrylic foam layer 2, the release film layer 1 and acrylic foam Layers 2 are stacked together, and the acrylic foam layer 2 is formed by coating and drying an acrylic foam coating solution, and the acrylic foam coating solution is made of the following components in parts by weight:

[0044]

[0045] A method for preparing a foam material, comprising the steps of:

[0046] In S1, first add 40 parts of ethyl acetate organic solvent and 1.8 parts of metal soap dispersant, mix and stir evenly, then add 2 parts of foamed microspheres, 3 parts of inorganic filler calcium carbonate, 1.5 parts of inorganic pigment titanium dioxide, and mix at high speed disperse and stir;

[0047] S2 After the above step S1, add 100 parts of solvent-based acrylic polymer resin, and after fully grinding and dispersing, add 0.8 parts of imidazole cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com