Industrial preparation method of Maillard peptide flavor salt

A technology of Maillard peptide and flavor salt, applied in the field of edible salt processing, can solve the problems of affecting taste, increasing the risk of excessive potassium ion intake, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

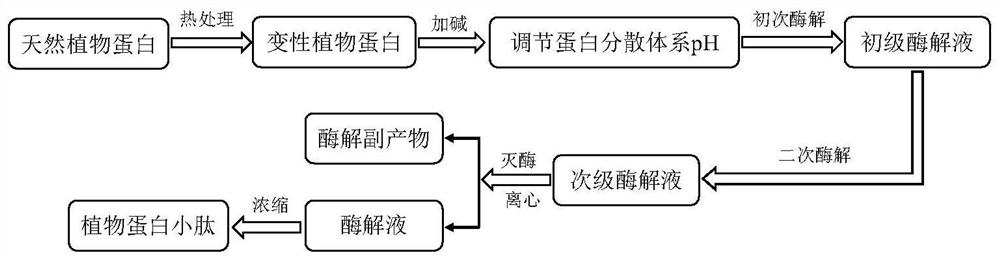

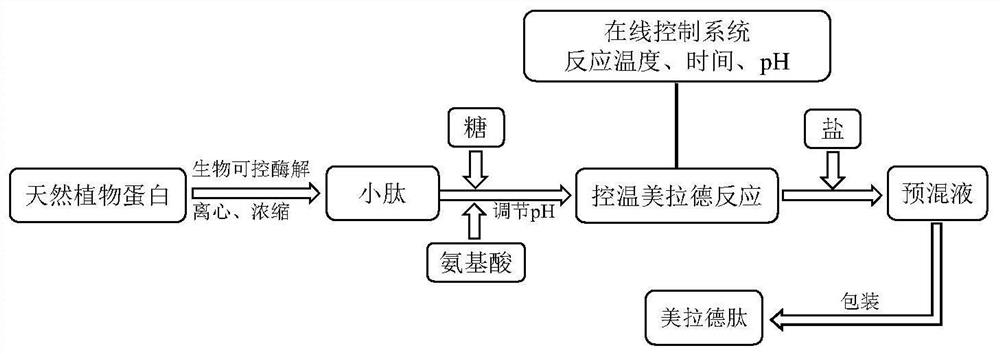

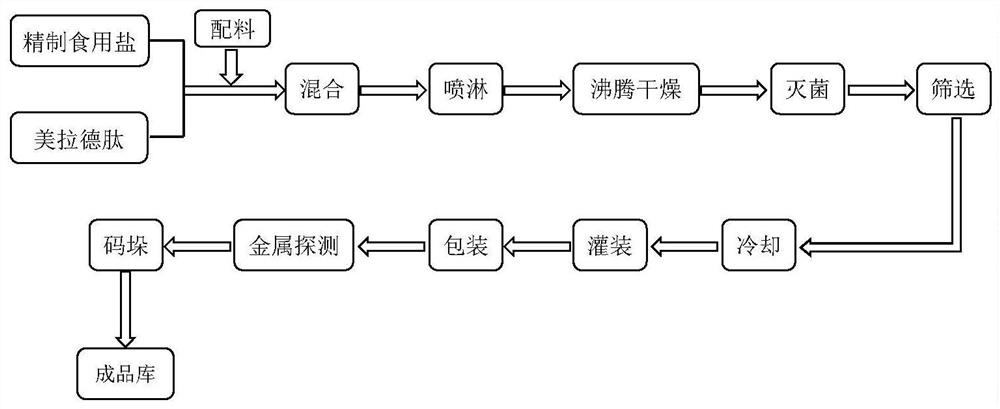

Method used

Image

Examples

Embodiment 1

[0043](1) 100 kg of soy protein is dissolved in water, and heat treatment degeneration is 60 min at 90 ° C, and the alkaline protease is mixed in the premixing tank, and the pH of the alkaline regulatory protein dispersion is 8.0; the mixture is introduced The primary enzymatic means, control the enzymatic hydrolysis temperature of 50 ° C, the enzymatic hydrolysis pH is 6.0, the amount of enzyme added is 0.5% (w / w), the enzymatic hydrolysis is 2 h, and the hydrolysis is 6.0, the degree of enzyme temperature is 80 ° C, After the reaction is completed, the circulating water is cooled; then the primary enzymatic hydrolyzide is introduced into the secondary enzymatic solution, add the aminogenase, control the enzymatic hydrolysis temperature of 70 ° C, the enzymatic pH is 8.0, the enzyme addition is 2.5% (W / W). ), The enzymatic hydrolysis time is 6 h, the hydrolysis is 10.0, the resection temperature is 100 ° C, and the reaction is completed after the reaction, the resulting enzymat...

Embodiment 2

[0058](1) 100 kg of corn protein is dissolved in water, heat treatment degeneration at 100 ° C for 30min, adding a flavor protease mixing in the premixing tank, and adds the pH of the base regulatory protein dispersion system to be 7.0; introduce the mixture into the primary level The enzymatic solution is controlled by 80 ° C, the enzymatic hydrolysis is 7.0, the enzyme addition is 2.5% (w / w), the enzymatic hydrolysis is 5 h, and the hydrolysis is 10.0, and the chemokile temperature is 100 ° C, the reaction After the end of the cycle water; then introduce the primary enzymatic hydrolyzate into the secondary enzymatic solution, add flavor protease, control the enzymatic hydrolysis temperature of 70 ° C, the enzymatic hydrolysis pH is 7.5, the enzyme addition is 2.5% (w / w), The enzymatic hydrolysis time is 6 h, the control water is 10.0, the resection temperature is 100 ° C, the reaction is completed after the reaction is centrifuged, the resulting enzymatic hydrolyzide is centri...

Embodiment 3

[0073]In the embodiment 1. Different from the plant protein as gluten protein, determine the corresponding conditions to prepare a small molecular protein peptide under the corresponding conditions, add the ribose to the Mei Lad to get the Merab product, take a mix, spray Leaching, boiling drying and other processes will be uniformly mixed with gluten salt and gluten peptide Melad product, resulting in a product for gluten powder Mead peptide salt; apply such a flavor to food, analyzed by electronic tongue ( See Table 7) The salt content of foods in the same kind of salt is significantly reduced, the overall flavor is coordinated, delicate, and the mellow flavor is significantly improved.

[0074]Table 7 Example 3 Gluten Metet Peptide Stri Salt Mechanized Strove Fresh Effect Evaluation

[0075]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com