A kind of sulfur-containing amino acid modified plant fruit polysaccharide and its preparation method and application

A technology of sulfur amino acid and amino acid, which is applied in the field of sulfur-containing amino acid modified plant fruit polysaccharides and its preparation, can solve the problems of inability to form a stable structure, polysaccharide solubility, heat stability and whitening effect can not be significantly improved, and achieve Effects of increased dosage, mild conditions, and ease of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

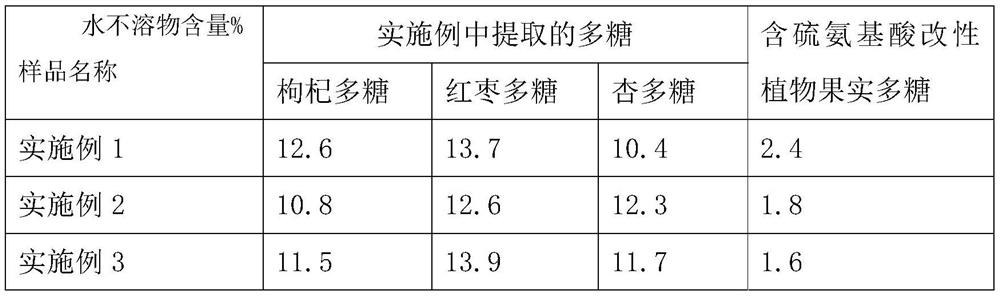

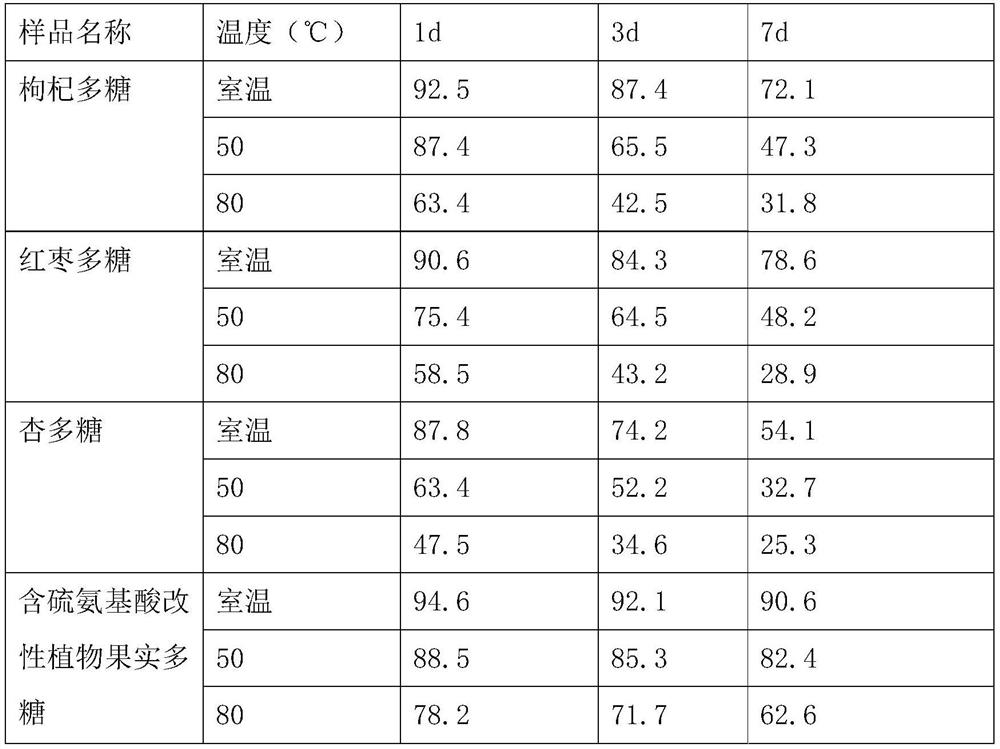

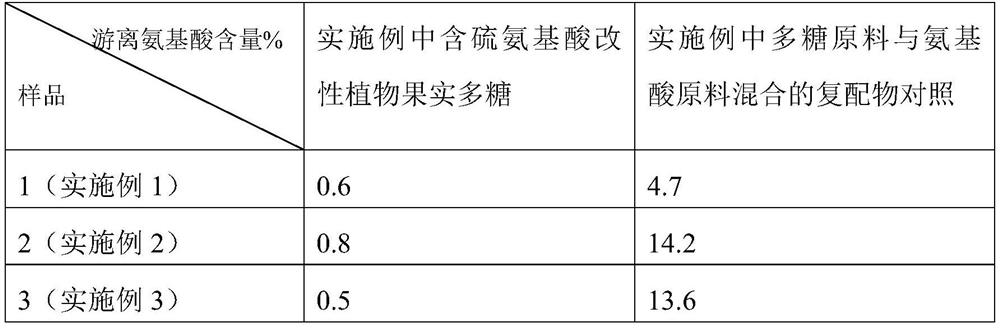

Examples

Embodiment 1

[0029] A sulfur-containing amino acid modified plant fruit polysaccharide, comprising 20 parts by weight of wolfberry polysaccharide, 20 parts by weight of jujube polysaccharide, 20 parts by weight of apricot polysaccharide, 1 part by weight of cysteine, 1 part by weight of cystine and 1 part by weight of methionine Parts, polysaccharide derivatives prepared by carbonyl ammonia reaction.

[0030] Its preparation includes the following steps:

[0031] (1) Add petroleum ether 10 times its mass to wolfberry, red dates or apricots, heat and reflux at 60°C for 8 hours; filter, add water to the filter residue according to 15 times its mass, extract 3 times at 90°C, 1 hour each time, filter, and combine the filtrates , 2MPa, 60°C reverse osmosis membrane concentrated to 20% solid matter concentration, add 4 times of 95% ethanol according to the volume ratio, stand at 4°C for 8h, filter, lyophilize the filter residue after volatilizing ethanol, and obtain Lycium barbarum , jujube or ...

Embodiment 2

[0035] A sulfur-containing amino acid modified plant fruit polysaccharide, comprising 30 parts by weight of wolfberry polysaccharide, 30 parts by weight of jujube polysaccharide, 30 parts by weight of apricot polysaccharide, 5 parts by weight of cysteine, 5 parts by weight of cystine, and 5 parts by weight of methionine Parts, polysaccharide derivatives prepared by carbonyl ammonia reaction.

[0036] Its preparation includes the following steps:

[0037] (1) add n-hexane 30 times its mass to wolfberry, red dates or apricots, heat and reflux at 90°C for 3 hours; The filtrates were combined, 3MPa, 40°C reverse osmosis membrane concentrated to 30% solid matter concentration, added 6 times 85% ethanol by volume ratio, stood at 4°C for 16h, filtered, lyophilized the filter residue after volatilizing ethanol, respectively Get wolfberry, red dates or apricot polysaccharides.

[0038] (2) Lycium barbarum polysaccharide, jujube polysaccharide and apricot polysaccharide are mixed in p...

Embodiment 3

[0041] A sulfur-containing amino acid modified plant fruit polysaccharide, comprising 30 parts by weight of wolfberry polysaccharide, 20 parts by weight of jujube polysaccharide, 20 parts by weight of apricot polysaccharide, 5 parts by weight of cysteine, 3 parts by weight of cystine, and 3 parts by weight of methionine Parts, polysaccharide derivatives prepared by carbonyl ammonia reaction.

[0042] Its preparation includes the following steps:

[0043] (1) Add petroleum ether 20 times its mass to wolfberry, red dates or apricots, heat and reflux at 80°C for 5 hours; filter, add water to the filter residue according to 20 times its mass, extract twice at 90°C, 1 hour each time, filter, and combine the filtrates , 2.5MPa, 50°C reverse osmosis membrane concentrated to 25% solid matter concentration, add 5 times of 80% ethanol by volume ratio, let stand at 4°C for 12h, filter, lyophilize the filter residue after volatilizing ethanol to obtain Lycium barbarum, jujube or apricot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com