Multi-effect continuous deamination evaporation system and method for performing valine deamination by using same

An evaporation system and high-efficiency evaporation technology, which can be used in multi-effect evaporation, separation methods, evaporator accessories, etc., can solve the problem of high ammonia content, and achieve the effects of high product yield, good deamination effect, and easy extraction and purification process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

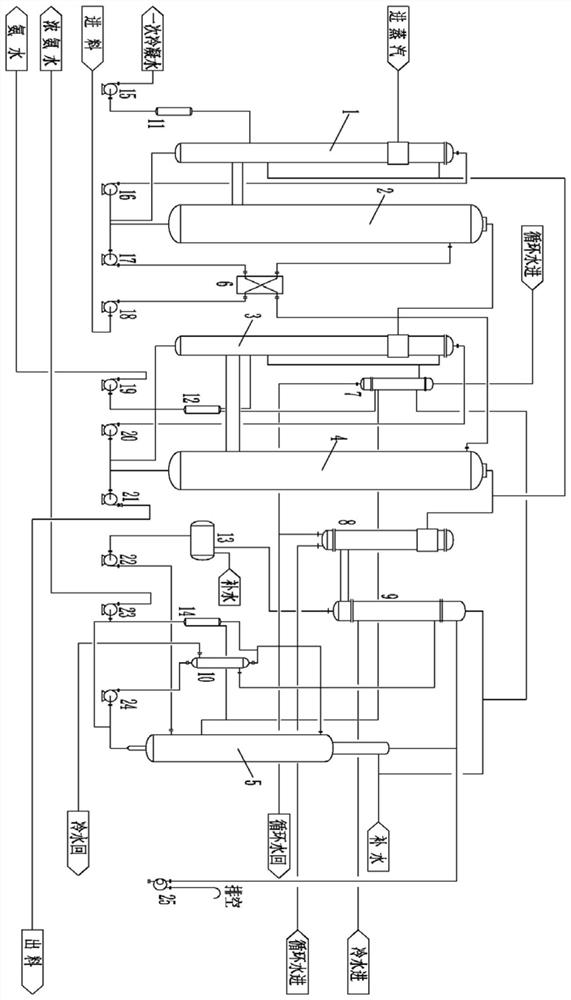

[0034] like figure 1 As shown, a multi-effect continuous deamination evaporation system includes a first-effect evaporator 1, a first-effect deamination tower 2, a second-effect evaporator 3, a second-effect deamination tower 4, an absorption tower 5, a preheater 6, a Effect tail cooler 7, second effect condenser 8, second effect tail cooler 9, absorption liquid cooler 10, primary condensed water storage tank 11, first ammonia water storage tank 12, second ammonia water storage tank 13, third ammonia water storage tank Tank 14, primary condensate pump 15, first-effect circulation pump 16, first-effect tower bottom pump 17, feed pump 18, ammonia water pump 19, second-effect circulation pump 20, second-effect tower bottom pump 21, dilute ammonia water pump 22, concentrated ammonia Water pump 23, absorption tower bottom pump 24 and vacuum pump 25;

[0035] The first-effect evaporator 1 is connected to the first-effect deamination tower 2 through a pipeline, the steam inlet of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com