A kind of preparation method of high-purity α-phase silicon nitride fiber felt

A technology of phase silicon nitride and fiber felt, which is applied in the field of preparation of high-purity α-phase silicon nitride, can solve the problems of high cost and lack of high-purity silicon nitride raw material powder, and achieve low price and high content of α-phase , the effect of easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

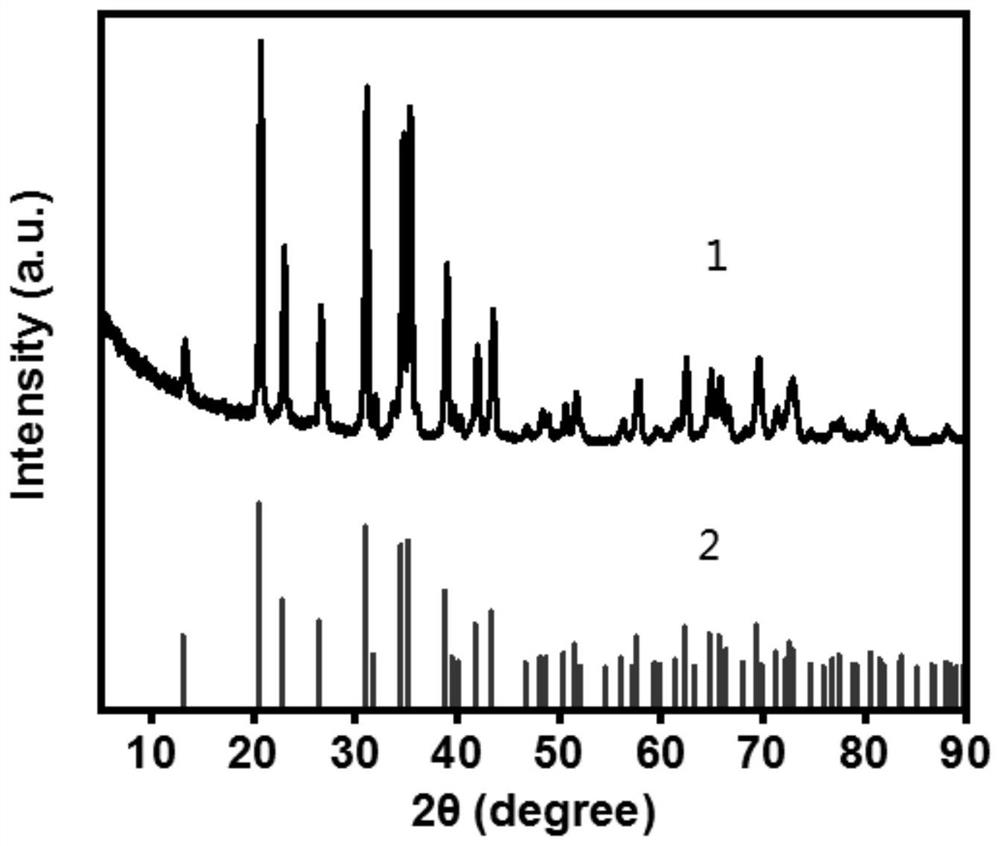

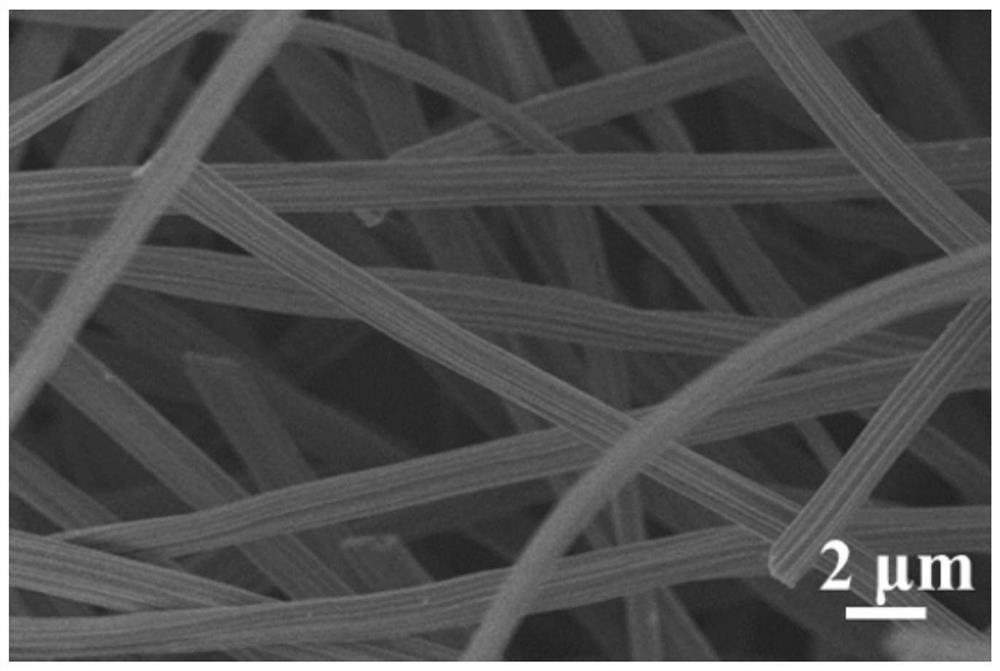

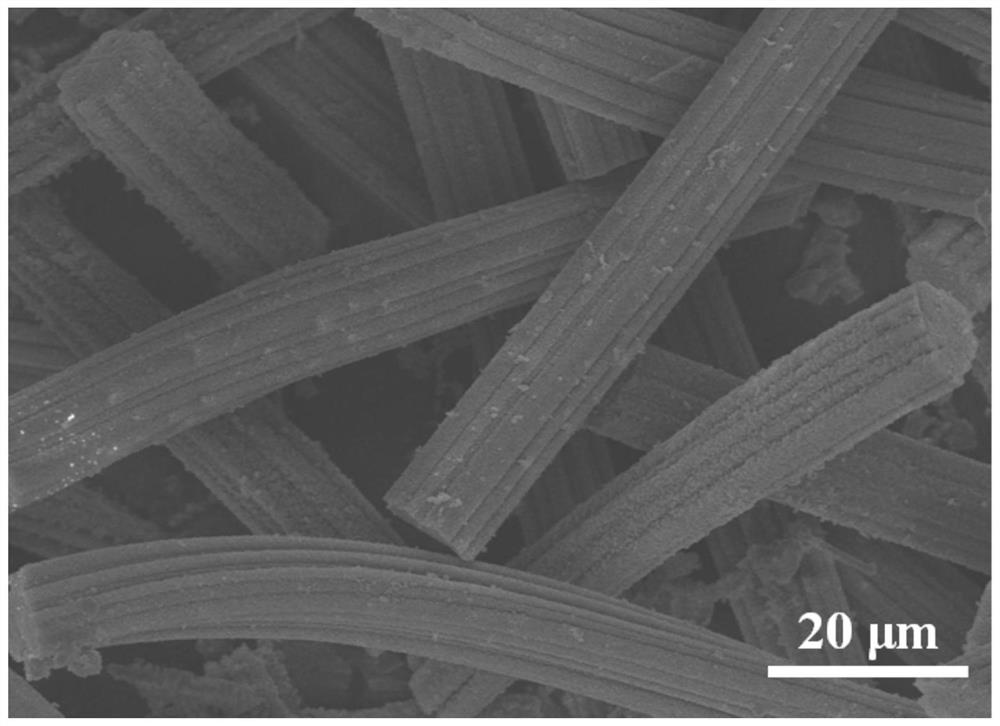

[0027] DETAILED DESCRIPTION one: one kind of the present embodiment, high purity α-phase preparation of silicon nitride fiber mat, which is done by the following steps:

[0028] A, preparing a carbon fiber mat precursors:

[0029] The carbon fiber mat was immersed in the mass percentage is 5% to 20% nitrate catalyst solution, the immersion time of 2h ~ 48h, and then dried in an oven to obtain a carbon fiber mat precursor;

[0030] Second, the sintering reaction:

[0031] Graphite crucible and the reaction of the silicon source powder laid on the crucible bottom of the graphite crucible to obtain reaction of the silicon source layer, and the carbon fiber mat precursor covers the upper surface of the reaction of the silicon source layer, filled with the reaction product was placed in a tube furnace at a flow rate of 0.05L / min ~ 2L / min nitrogen gas as the reaction gas, the reaction temperature is at 1200 ℃ ~ 1800 ℃ under sintering reaction 0.5h ~ 24h, allowed to cool to room temp...

specific Embodiment approach 2

[0045]DETAILED DESCRIPTION OF THE INVENTION Different: The present embodiment differs from the specific embodiment that the nitrate catalyst solution described in step one is a nitrate solution, a cobalt nitrate solution or a copper nitrate solution. Others are the same as those of the specific embodiments.

specific Embodiment approach 3

[0046] DETAILED DESCRIPTION OF THE INVENTION 3: The present embodiment is different from one or two of the specific embodiment: The drying of the drying temperature in the oven is in the oven, drying 2H ~ 12H under conditions of the drying temperature of 40 ° C to 180 ° C. . Others are the same as those of the specific embodiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com