System and method for efficiently and continuously producing anhydrous iron phosphate

An anhydrous phosphoric acid, high-efficiency technology, used in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as bulky, unnecessarily increased energy consumption, and lower than surface material temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

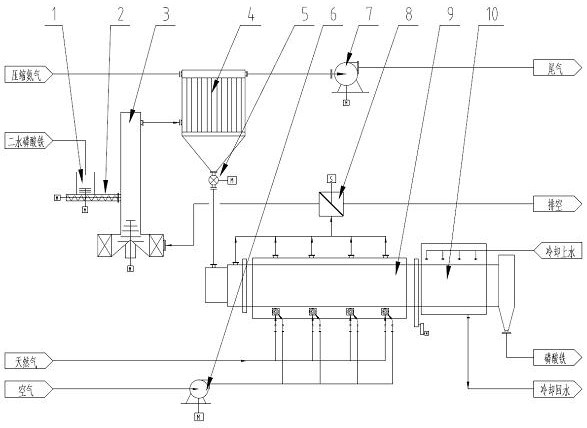

[0021] like figure 1 As shown, a system for efficient and continuous production of anhydrous ferric phosphate, the system includes a broken arch feeding barrel 1, a rotary flash dryer 3 and a gas-fired rotary roaster 9.

[0022] The bottom of the arch-breaking feeding barrel 1 is provided with a feeding screw 2, which is connected to the spin flash dryer 3; the spin flash dryer 3 is connected to the bag filter 4 and the emptying pipe respectively; the bag filter One side of 4 is provided with compressed nitrogen input pipe, and the other side is connected with tail gas pipe through induced draft fan 7, and the bottom is connected with gas type rotary roaster 9 through rotary discharge valve 5; The top of gas type rotary roaster 9 is provided with The four-way valve 8 connected to the spin flash dryer 3, the furnace is respectively connected with a natural gas input pipe and an air input pipe with a combustion-supporting fan 6, and the tail is connected with a cooling section 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com