Steel enterprise cold rolling oily wastewater treatment method

A wastewater treatment and enterprise technology, applied in metallurgical wastewater treatment, water/sewage treatment, flotation water/sewage treatment, etc., can solve the problems that restrict the production of high-quality products and sustainable development of iron and steel enterprises, and the high cost of nanofiltration membranes , the problem of unstable operation water quality, etc., to achieve the effect of promoting the improvement of water environment, stable treatment effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

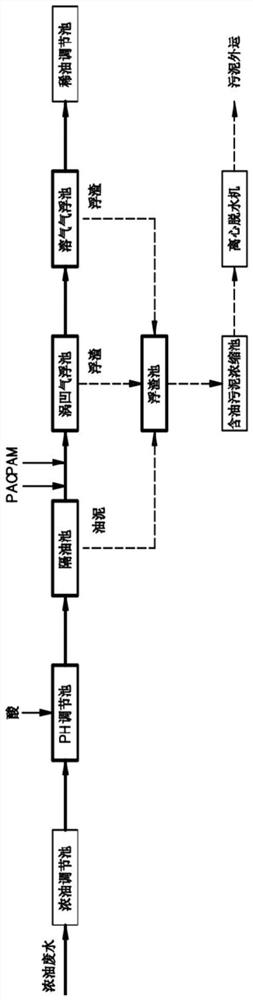

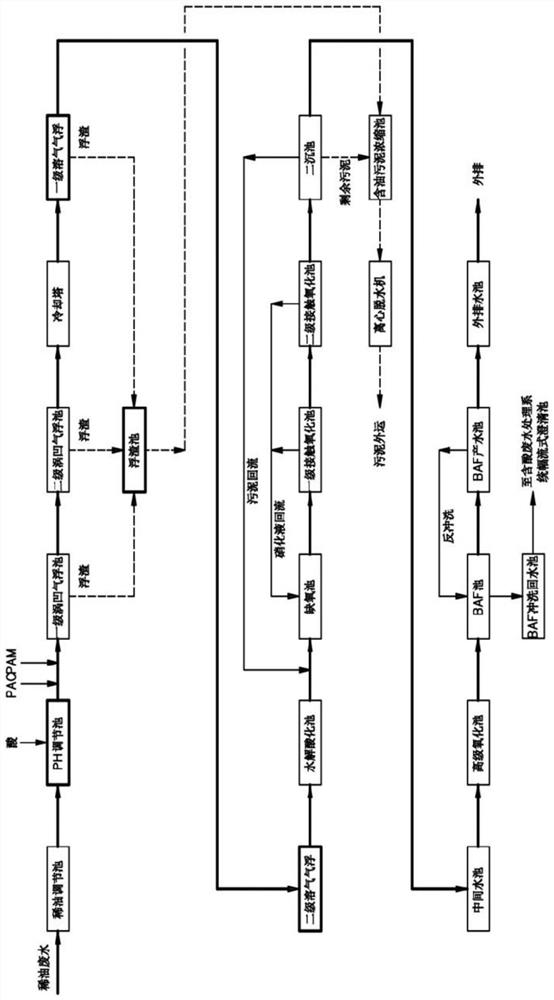

[0030]The technical solutions in the embodiments of the present invention will be described in conjunction with the accompanying drawings, as described herein is merely the embodiments of the invention, not all embodiments.

[0031]The COD value of the concentrated oil wastewater generated by a steel enterprise rolling process 20000mg / L, ammonia nitrogen 150mg / L, suspension 300mg / L, oil 60mg / L;

[0032]The rolling steel process produced by the COD value of 1000 mg / L, ammonia nitrogen 100 mg / L, suspension of 100 mg / L, oil 40 mg / L.

[0033]The above-described wastewater is treated by the oil-containing wastewater treatment method of the present invention, and the main process flow is:

[0034](1) Treatment of concentrated oil wastewater

[0035]A. The concentrated oil wastewater generated by the rolling process first enters the concentrated oil regulating pool to adjust the water volume and water quality, and enter the concentrated oil pH adjustment tank after heating through steam, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com