Corrosion-resistant gas conveying component and plasma processing device thereof

A plasma and processing device technology, applied in the field of plasma processing devices, can solve problems such as metal pollution and solid particle pollution, and achieve the effects of reducing waste, preventing corrosion and solving parameter drift.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

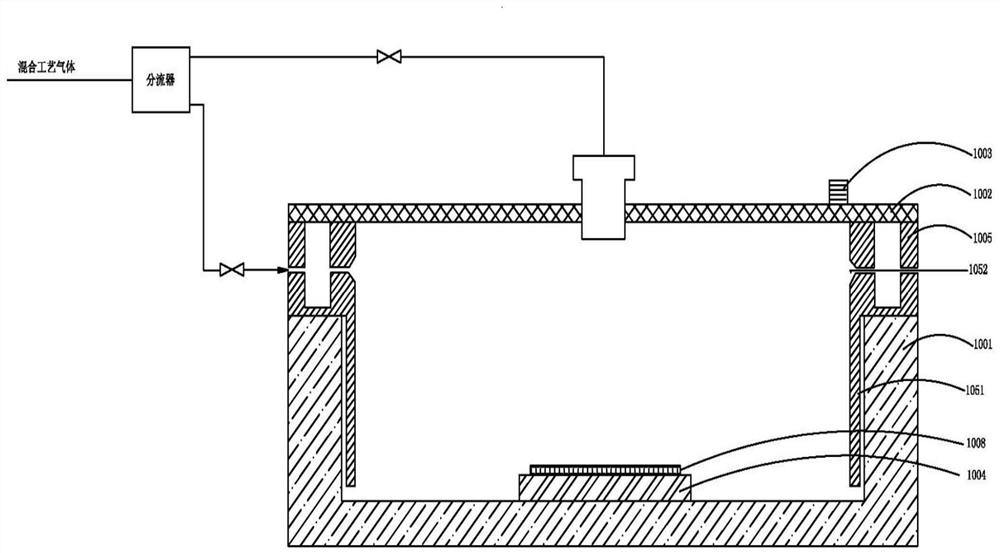

[0046] In this embodiment, the plasma processing device is an inductively coupled plasma processing device (ICP device).

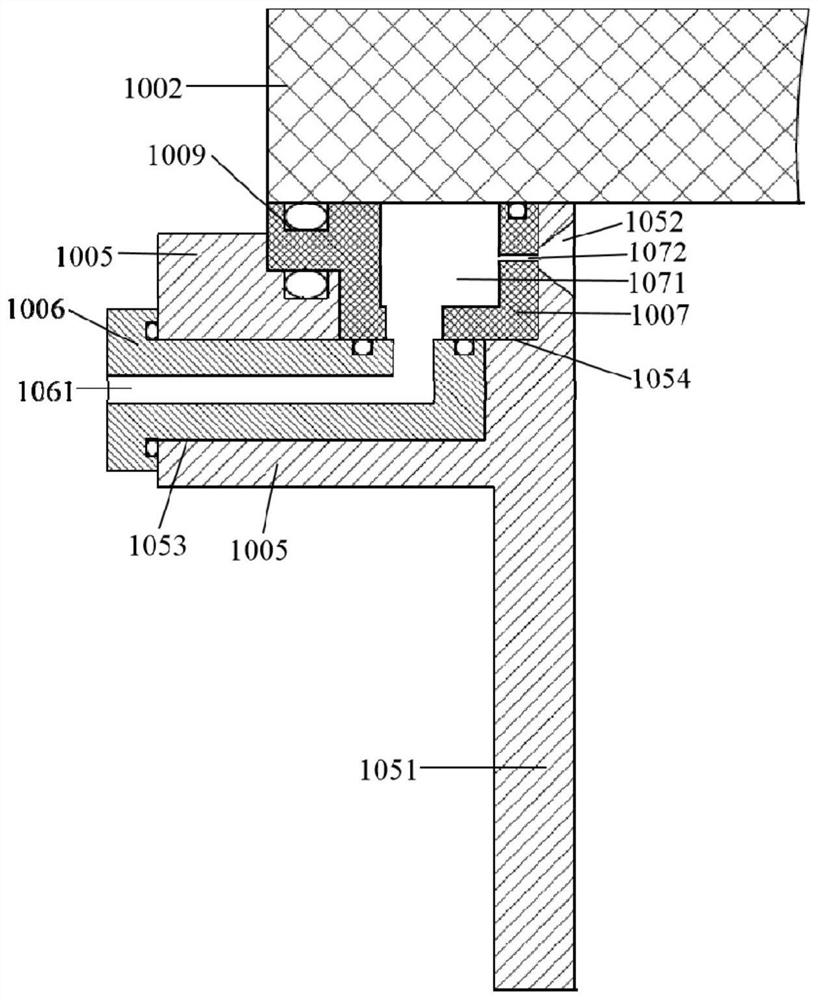

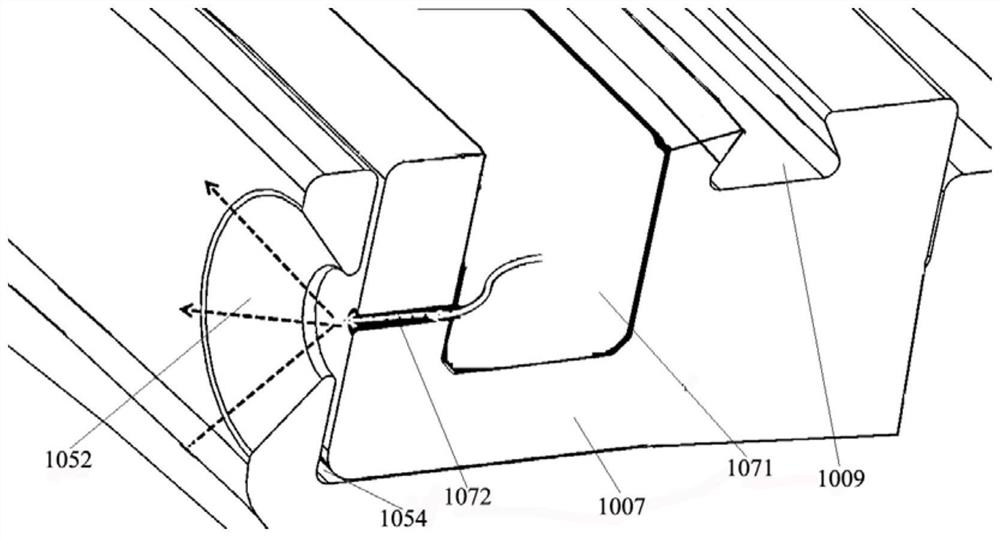

[0047] Such as figure 1Shown is an inductively coupled plasma processing device of this embodiment. The radio frequency power loaded on the inductive coupling coil 1003 is coupled into the reaction chamber 1001 through the dielectric window 1002 to form an electron region in the reaction chamber 1001 to ionize the process gas supplied to the reaction chamber 1001 through the gas delivery system to form plasma or The ions are used to etch the wafer 1008 placed on the base 1004 at the bottom of the reaction chamber 1001 . A liner body 1005 (liner) is arranged around the side wall of the reaction chamber 1001 , and the liner body 1005 supports the edge of the dielectric window 1002 above it. The liner main body 1005 is grounded by contacting the cavity, and a baffle 1051 extending downward from the inner wall of the liner main body 1005 surrounds the inner ...

Embodiment 2

[0059] Based on the structural characteristics of the inductively coupled plasma processing device in Embodiment 1, this embodiment makes some changes to the structure of the liner body 2005, mainly for the inner side wall of the liner body 2005 and the diffusion accommodation space 2054. changed.

[0060] Such as Figure 4 Shown is a schematic structural diagram of the gas conveying part of the inductively coupled plasma processing apparatus of this embodiment. Compared with Embodiment 1, the inner wall of the bushing body 2005 in this embodiment does not have the air outlet hole 1052, and the diffusion accommodation space 2054 is a step, and the gas in the diffusion accommodation space 2054 diffuses The inner wall of the part 2007 directly contacts the environment of the reaction chamber 2001, and the process gas is transported from the gas pipeline to the gas diffusion channel 2071 of the gas diffusion part 2007 through the gas inlet channel 2061 of the gas inlet delivery ...

Embodiment 3

[0063] Based on the structural characteristics of the inductively coupled plasma processing device in the second embodiment, this embodiment makes some changes to the structure of the gas diffusion part 3007, mainly for the gas diffusion channel 3071 in the gas diffusion part 3007 .

[0064] Such as Figure 5 Shown is a schematic structural diagram of the gas conveying part of the inductively coupled plasma processing apparatus of this embodiment. Compared with Embodiment 2, the gas diffusion channel 3071 of the gas diffusion component 3007 in this embodiment is a closed gas channel, such as a channel with a circular cross-section, and the dielectric window 3002 contacts the upper surface of the gas diffusion component 3007 without contacting the upper surface of the gas diffusion component 3007. The gas diffusion channels 3071 are in contact. The process gas delivery process of the device is the same as that of the second embodiment. It should be noted that the diffusion a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com