Thermal buffer fiber modified diaphragm for lithium battery and preparation method

A fiber modification and thermal buffering technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as low production efficiency, unsatisfactory modification effect, and poor heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

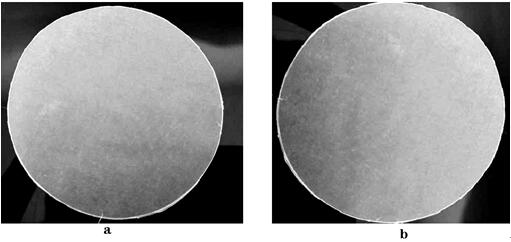

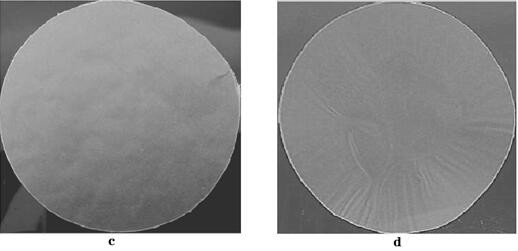

Image

Examples

Embodiment 1

[0037](1) First add urea into a formaldehyde solution with a mass concentration of 37% to fully dissolve, 10 parts by weight of urea and 20 parts by weight of formaldehyde solution; then use triethanolamine to adjust the pH value to 9, then heat the reaction in a water bath, and the temperature of the water bath is 80°C , the reaction time is 1h; then let it stand and cool to room temperature naturally, and finally adjust the pH value to neutral to obtain a urea-formaldehyde resin prepolymer solution;

[0038] (2) First mix the urea-formaldehyde resin prepolymer solution prepared in step (1) with sepiolite powder and polyethylene glycol with a molecular weight of 10000, 90 parts by weight of urea-formaldehyde resin prepolymer solution, 5 parts by weight of sepiolite powder 10 parts of polyethylene glycol with a molecular weight of 10000; then disperse for 40 minutes in an ultrasonic machine with a frequency of 50 kHz to obtain a spinning solution;

Embodiment 2

[0042] (1) First add urea into a formaldehyde solution with a mass concentration of 37% to fully dissolve, 15 parts by weight of urea and 30 parts by weight of formaldehyde solution; then use triethanolamine to adjust the pH value to 9, then heat the reaction in a water bath, and the temperature of the water bath is 80°C , the reaction time is 1h; then let it stand and cool to room temperature naturally, and finally adjust the pH value to neutral to obtain a urea-formaldehyde resin prepolymer solution;

[0043] (2) First mix the urea-formaldehyde resin prepolymer solution prepared in step (1) with sepiolite powder and polyethylene glycol with a molecular weight of 10000, 100 parts by weight of urea-formaldehyde resin prepolymer solution, and 8 parts by weight of sepiolite powder 15 parts of polyethylene glycol with a molecular weight of 10000; then disperse for 30 minutes in an ultrasonic machine with a frequency of 50 kHz to obtain a spinning solution;

[0044] (3) The spinni...

Embodiment 3

[0047] (1) First add urea into a formaldehyde solution with a mass concentration of 37% to fully dissolve, 15 parts by weight of urea and 30 parts by weight of formaldehyde solution; then use triethanolamine to adjust the pH value to 9, then heat the reaction in a water bath, and the temperature of the water bath is 80°C , the reaction time is 2h; then stand and cool to room temperature naturally, and finally adjust the pH value to neutral to obtain a urea-formaldehyde resin prepolymer solution;

[0048] (2) First mix the urea-formaldehyde resin prepolymer solution prepared in step (1) with sepiolite powder and polyethylene glycol with a molecular weight of 10000, 110 parts by weight of urea-formaldehyde resin prepolymer solution, 10 parts by weight of sepiolite powder 15 parts of polyethylene glycol with a molecular weight of 10000; then disperse for 40 minutes in an ultrasonic machine with a frequency of 50 kHz to obtain a spinning solution;

[0049] (3) The spinning solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com