Method and apparatus for cutting transparent brittle material

A technology for brittle materials and cutting devices, applied in welding/welding/cutting items, laser welding equipment, manufacturing tools, etc., can solve the problems of short depth of focus, low spot energy density, and large volume of linear motors, etc., to achieve long depth of focus, The effect of high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

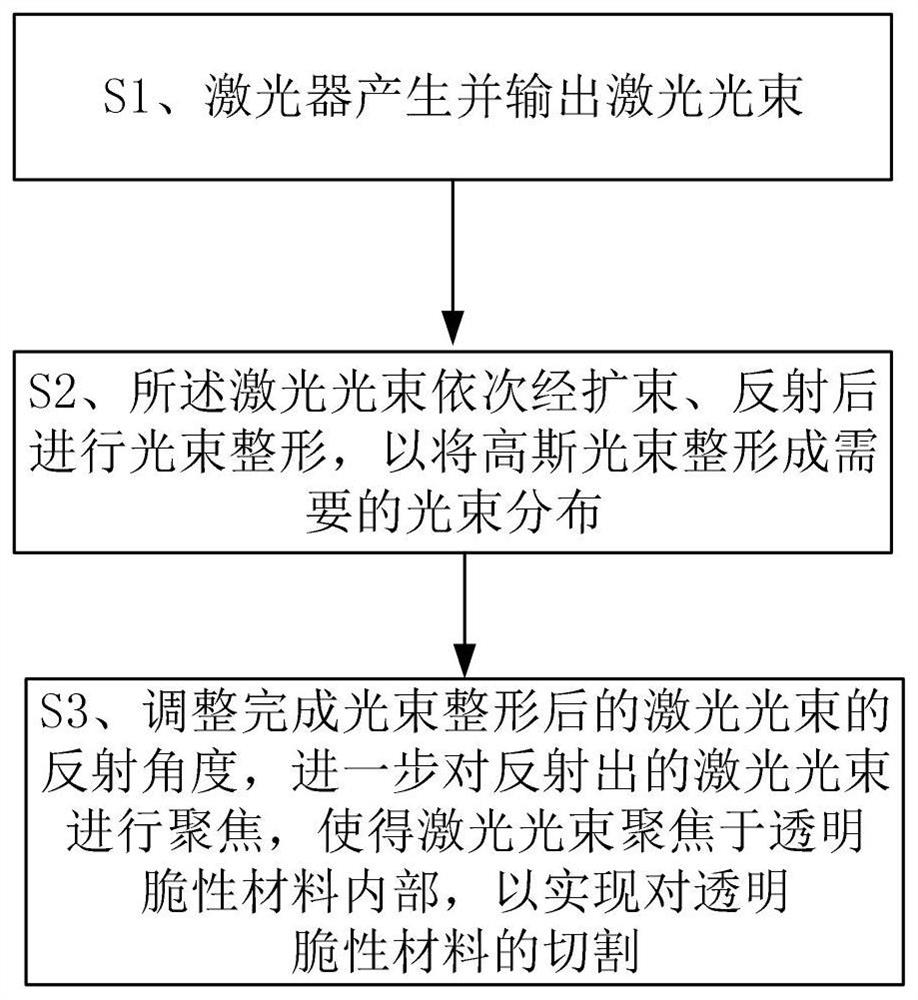

[0038] Such as figure 1 As shown, the present embodiment provides a method for cutting transparent and brittle materials, which includes the following steps:

[0039] S1. The laser generates and outputs a laser beam;

[0040] S2. The laser beam is sequentially expanded and reflected to perform beam shaping, so as to shape the Gaussian beam into a required beam distribution, so as to meet the cutting requirements of different transparent and brittle materials; in this embodiment, the transparent and brittle materials include or Sapphire, etc., the beam shaping can be realized by one or more of beam shaping systems such as conical mirrors, DOE (Difractive Optical Element, diffractive optical elements), spatial modulators, etc.;

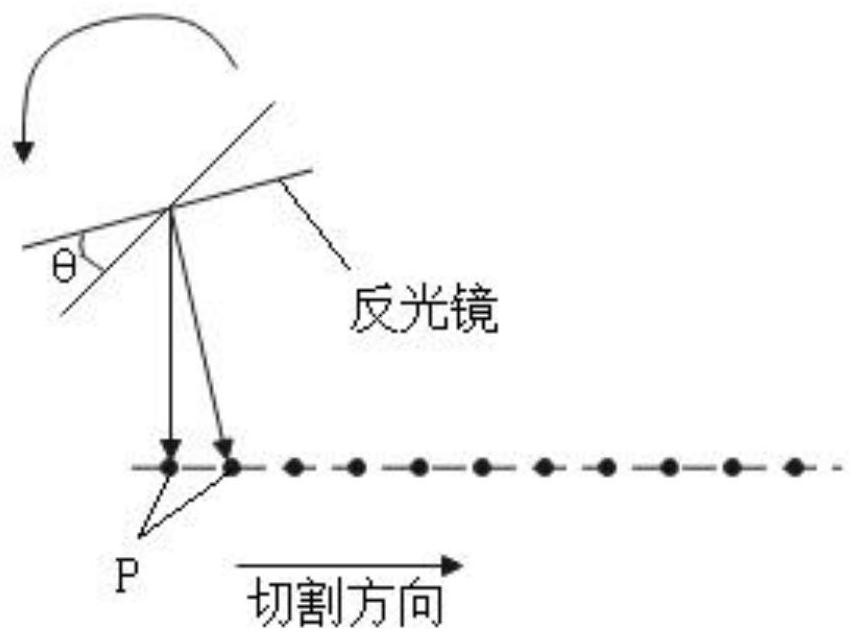

[0041] S3. Adjust the reflection angle of the laser beam after beam shaping, and further focus the reflected laser beam, so that the laser beam is focused inside the transparent and brittle material, so as to realize the cutting of the transparent and ...

Embodiment 2

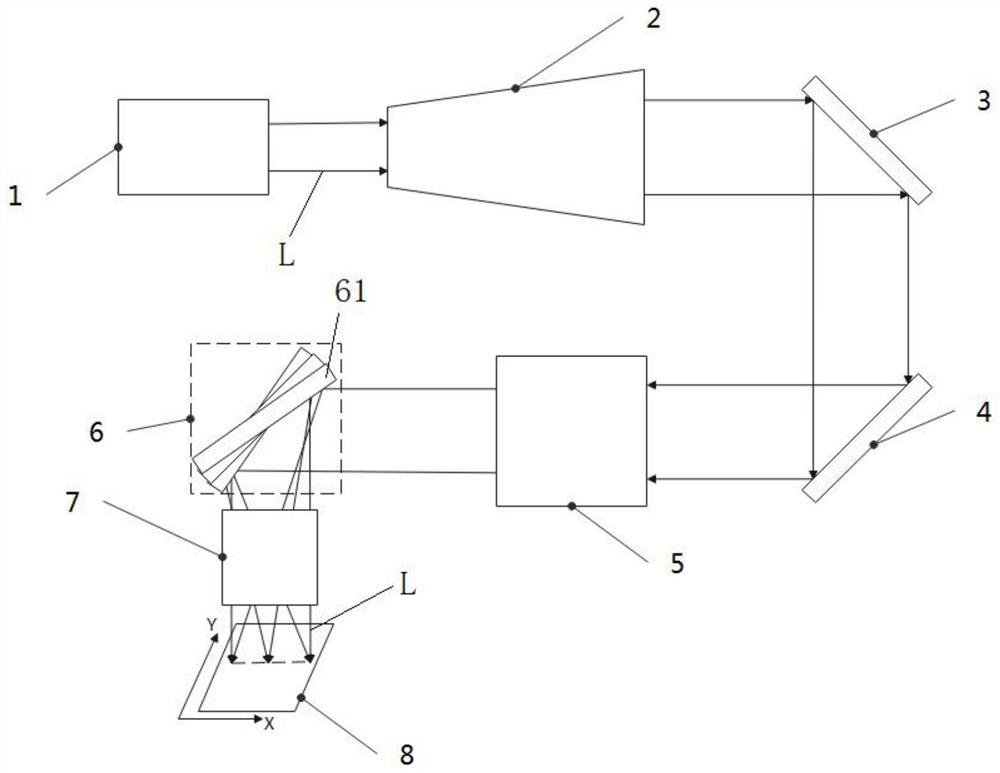

[0048] This embodiment provides a transparent brittle material cutting device for realizing the method described in Embodiment 1, such as image 3 shown, which includes:

[0049] a laser 1, which is used to generate and output a laser beam L;

[0050] Beam expander 2, which is used to adjust the laser spot size and divergence angle;

[0051]Mirror group, beam shaping system 5, the mirror group is used to reflect the laser beam L after the beam expander 2 beam expansion to the beam shaping system 5, so that the Gaussian beam is shaped into the desired shape by the beam shaping system 5 Beam distribution to meet the cutting requirements of different transparent and brittle materials 8; in this embodiment, the transparent and brittle materials 8 include glass or sapphire, and the beam shaping system 5 includes conical mirrors, DOE (Difractive Optical Element, diffractive optical element ), one or more of spatial modulators, etc.;

[0052] A high-speed scanning system 6, which ...

Embodiment 3

[0060] The only difference between this embodiment and Embodiment 2 is that the transparent and brittle material cutting device in this embodiment also includes:

[0061] The Z-direction lifting device is used to drive the transparent and brittle material 8 to move in the Z direction, so as to adjust the position of the focal plane.

[0062] The transparent and brittle material cutting device of this embodiment can adjust the laser beam distribution and focal depth by adjusting the distance between the beam shaping system 5 and the focusing system 7, and adapt different powers according to the light output frequency of the laser, combined with the deflection angle of the mirror The scanning speed and accuracy can be adjusted by controlling the scanning speed, so as to meet the cutting process requirements of different transparent and brittle materials.

[0063] In summary, the present invention is specifically applicable to the cutting of transparent and brittle materials such...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com