Biological purification block based on municipal sludge as well as preparation method and application thereof

A municipal sludge and biological purification technology, applied in chemical instruments and methods, water pollutants, biological water/sewage treatment, etc., can solve the problems of inability to purify water for a long time, poor adsorption performance of permeable bricks, etc., and achieve efficient use of solid waste Physical function, improving immobilization and adsorption, strong water absorption and water holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

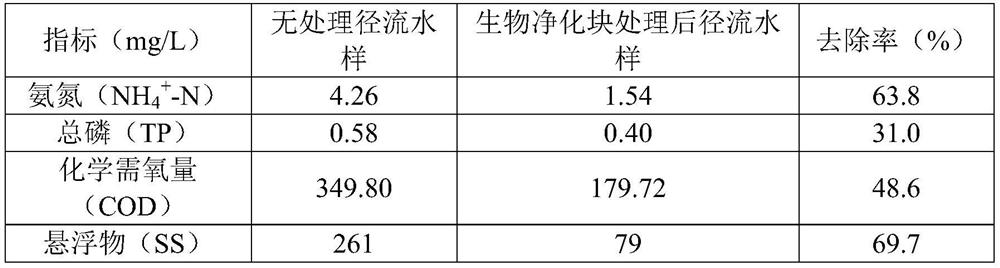

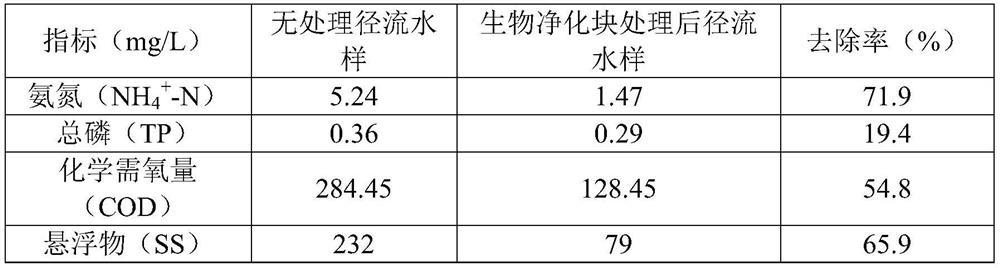

Embodiment 1

[0039] 1. Preparation of mixed bacterial agent

[0040] Mix the dormant bacterial agent of Bacillus amyloliquefaciens IAE and the dormant bacterial agent of Trichoderma aculeatus 12 according to the mass ratio of 1:3, and mix thoroughly to form a mixed bacterial agent.

[0041] 2. High temperature stacking of municipal sludge

[0042] Inoculate the mixed bacterial agent into the dewatered municipal sludge according to the mass ratio of 1%, and add the crushed wheat straw with a length of 2-50mm according to the mass ratio of 30% to the municipal sludge, and the water content of the pile is 60%, and mix well. Trough stacking, the stacking height is 2m, the central stacking temperature is maintained at 60°C for 14 days, the stacking is turned over and repeated 3 times, and the fermentation stacking period is 40 days. The municipal sludge used is mechanically dewatered sludge from a water treatment plant, with a water content of 80%, and the contents of heavy metals and pathogen...

Embodiment 2

[0051] 1. Preparation of mixed bacterial agent

[0052] Mix the dormant bacterial agent of Bacillus amyloliquefaciens IAE and the dormant bacterial agent of Trichoderma aculeatus 12 according to the mass ratio of 2:5, and thoroughly mix into a mixed bacterial agent.

[0053] 2. High temperature stacking of municipal sludge

[0054] Inoculate the mixed bacterial agent into the dewatered municipal sludge according to the mass ratio of 2%, and add the ground rice straw with a length of 2-50mm according to the mass ratio of 50% to the municipal sludge, and the water content of the pile is 50%, mix well, and strip Pile stacking, the stacking height is 3m, the central stacking temperature is maintained at 70°C for 20 days, the stacking is turned over, and repeated 5 times, and the fermentation stacking period is 30 days. The municipal sludge used is mechanically dewatered sludge from sewage treatment plants, with a water content of 82%, and the contents of heavy metals and pathogen...

Embodiment 3

[0062] 1. Preparation of mixed bacterial agent

[0063] Mix the dormant bacterial agent of Bacillus amyloliquefaciens IAE and the dormant bacterial agent of Trichoderma aculeatus 12 according to the mass ratio of 1:1, and mix thoroughly to form a mixed bacterial agent.

[0064] 2. High temperature stacking of municipal sludge

[0065] Inoculate the mixed bacterial agent into the dewatered municipal sludge according to the mass ratio of 2%, and add the crushed corn stalks with a length of 2-50mm according to the mass ratio of 20% to the municipal sludge, and the water content of the pile is 65%, mix well, and strip Pile stacking, the stacking height is 5m, the central stacking temperature is maintained at 70°C for 20 days, the stacking is turned over, and repeated 5 times, and the fermentation stacking period is 40 days. The municipal sludge used is mechanically dewatered sludge from sewage treatment plants, with a water content of 82%, and the contents of heavy metals and pat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com