UV (ultraviolet) photocuring multifunctional epoxy reactive diluent and preparation method thereof

A multifunctional epoxy, reactive diluent technology, applied in epoxy resin coatings, silicone compounds, coatings, etc., can solve problems such as poor compatibility, poor cured film state, and poor curing effect. Achieve the effects of good compatibility, overcoming poor curing effect, and simple and efficient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of UV light curing multifunctional epoxy reactive diluent:

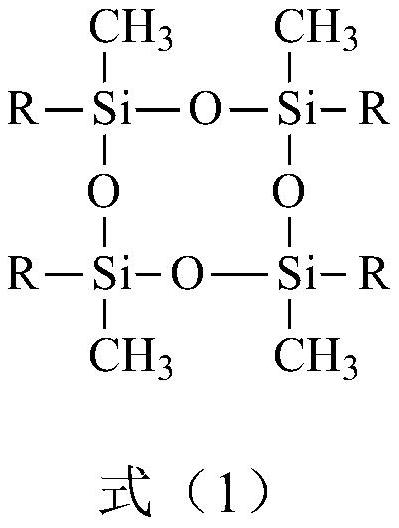

[0037] S1. Under the condition of nitrogen gas, mix 1mol tetramethyltetravinylcyclotetrasiloxane, 100ml n-hexane, and 200μg Speier catalyst into the reactor, and add 4mol tetramethyldisiloxane dropwise at 60°C Alkanes, after the dropwise addition, stirred and reacted at 60°C for 5h;

[0038] S2. Add 4 mol of allyl glycidyl ether dropwise to the reaction system obtained in step S1 under the condition of nitrogen flow. After the dropwise addition, stir the reaction at 60°C for 5h, and then reduce the pressure at 100°C and -0.1MPa Distilled for 1h, that is.

[0039] The structural formula of the prepared UV photocuring multifunctional epoxy reactive diluent is as follows:

[0040]

[0041] Preparation of photocurable coatings: the silicone photocurable resin containing epoxy groups, HPF 6 Mix evenly with the above-mentioned UV light-curable multifunctional epoxy reactive diluent in a mass ratio ...

Embodiment 2

[0045] Preparation of UV light curing multifunctional epoxy reactive diluent:

[0046] S1. Under the condition of blowing nitrogen, mix 1mol tetramethyltetravinylcyclotetrasiloxane, 100ml n-hexane, and 200μg Speier catalyst evenly and add them into the reactor, add 4mol terminal hydrogen-containing silicone oil dropwise at 60°C, drop After the addition was complete, the reaction was stirred at 60°C for 5 h;

[0047] S2. Add 4 mol of allyl glycidyl ether dropwise to the reaction system obtained in step S1 under the condition of nitrogen flow. After the dropwise addition, stir the reaction at 60°C for 5h, and then reduce the pressure at 100°C and -0.1MPa Distilled for 1h, that is;

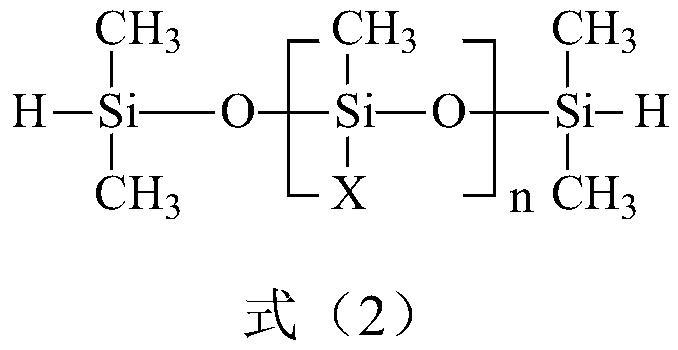

[0048] In S1, the structural formula of the terminal hydrogen-containing silicone oil is as follows:

[0049]

[0050] In the formula, n is 1-1000.

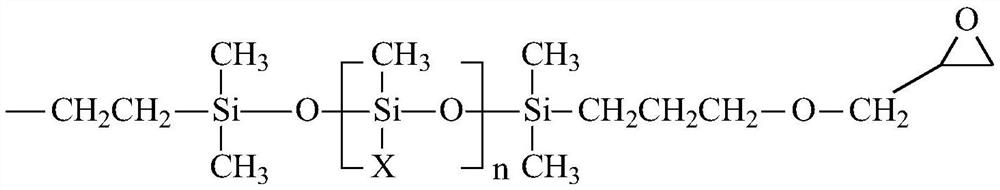

[0051] The structural formula of the prepared UV photocuring multifunctional epoxy reactive diluent is as follows:

[0052]

[0053] In the f...

Embodiment 3

[0058] Preparation of UV light curing multifunctional epoxy reactive diluent:

[0059] S1. Under the condition of blowing nitrogen, mix 1mol tetramethyltetravinylcyclotetrasiloxane, 100ml n-hexane, and 200μg Speier catalyst into the reactor, add dropwise 4mol terminal hydrofluorosilicone oil at 60°C, After the dropwise addition, the reaction was stirred at 60° C. for 5 h;

[0060] S2. Add 4 mol of allyl glycidyl ether dropwise to the reaction system obtained in step S1 under the condition of nitrogen flow. After the dropwise addition, stir the reaction at 60°C for 5h, and then reduce the pressure at 100°C and -0.1MPa Distilled for 1h, that is;

[0061] In S1, the structural formula of the end-containing hydrofluorosilicone oil is as follows:

[0062]

[0063] In the formula, n is 1-1000.

[0064] The structural formula of the prepared UV photocuring multifunctional epoxy reactive diluent is as follows:

[0065]

[0066] In the formula, n is 1-1000.

[0067] Preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com