Acrylic plate with excellent bending performance and preparation method thereof

A technology of acrylic board and bending performance, which is applied in the field of acrylic board, can solve the problems of brittle acrylic board, poor bending performance, low impact strength, etc., and achieve the goals of increased flexibility, reduced side base volume, and improved impact strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

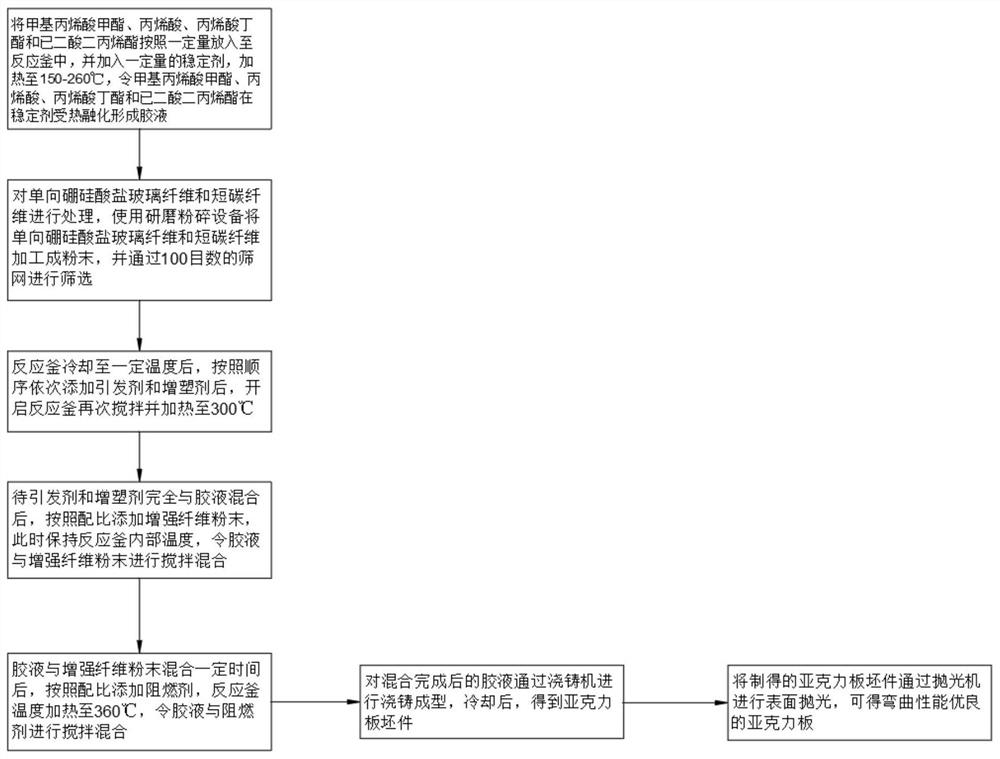

Method used

Image

Examples

Embodiment 1

[0026] An acrylic plate with excellent bending performance and its preparation method, the following parts are taken: polymerized monomers, initiators, stabilizers, plasticizers, reinforcing fibers and flame retardants, and the polymerized monomers are composed of methyl methacrylate , acrylic acid, butyl acrylate, and dipropylene adipate tetrapolymerization, and the reinforcing fibers include unidirectional borosilicate glass fibers and short carbon fibers, of which:

[0027] The content of the polymerized monomer is 100 parts of methyl methacrylate, 0 parts of acrylic acid, 10 parts of butyl acrylate, and 10 parts of dipropylene adipate. The composition of the reinforcing fiber is 2 parts of unidirectional borosilicate glass fiber, short Carbon fiber 2 parts.

[0028] Further, the initiator is one or more combinations of azobisisovaleronitrile, azobisisobutyronitrile, and benzoyl peroxide, wherein:

[0029] The initiator is 10 parts of azobisisovaleronitrile, 5 parts of azo...

Embodiment 2

[0047] An acrylic plate with excellent bending performance and its preparation method, the following parts are taken: polymerized monomers, initiators, stabilizers, plasticizers, reinforcing fibers and flame retardants, and the polymerized monomers are composed of methyl methacrylate , acrylic acid, butyl acrylate, and dipropylene adipate tetrapolymerization, and the reinforcing fibers include unidirectional borosilicate glass fibers and short carbon fibers, of which:

[0048] The content of polymerized monomers is 100 parts of methyl methacrylate, 15 parts of acrylic acid, 30 parts of butyl acrylate, and 30 parts of dipropylene adipate. The composition of the reinforcing fiber is 6 parts of unidirectional borosilicate glass fiber, short Carbon fiber 4 parts.

[0049] Further, the initiator is one or more combinations of azobisisovaleronitrile, azobisisobutyronitrile, and benzoyl peroxide, wherein:

[0050] The initiator is 15 parts of azobisisovaleronitrile, 10 parts of azob...

Embodiment 3

[0068] An acrylic plate with excellent bending performance and its preparation method, the following parts are taken: polymerized monomers, initiators, stabilizers, plasticizers, reinforcing fibers and flame retardants, and the polymerized monomers are composed of methyl methacrylate , acrylic acid, butyl acrylate, and dipropylene adipate tetrapolymerization, and the reinforcing fibers include unidirectional borosilicate glass fibers and short carbon fibers, of which:

[0069] The content of the polymerized monomer is 100 parts of methyl methacrylate, 10 parts of acrylic acid, 20 parts of butyl acrylate, and 15 parts of dipropylene adipate. The composition of the reinforcing fiber is 12 parts of unidirectional borosilicate glass fiber, short Carbon fiber 2 parts.

[0070] Further, the initiator is one or more combinations of azobisisovaleronitrile, azobisisobutyronitrile, and benzoyl peroxide, wherein:

[0071] The initiator is 20 parts of azobisisovaleronitrile, 2 parts of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com