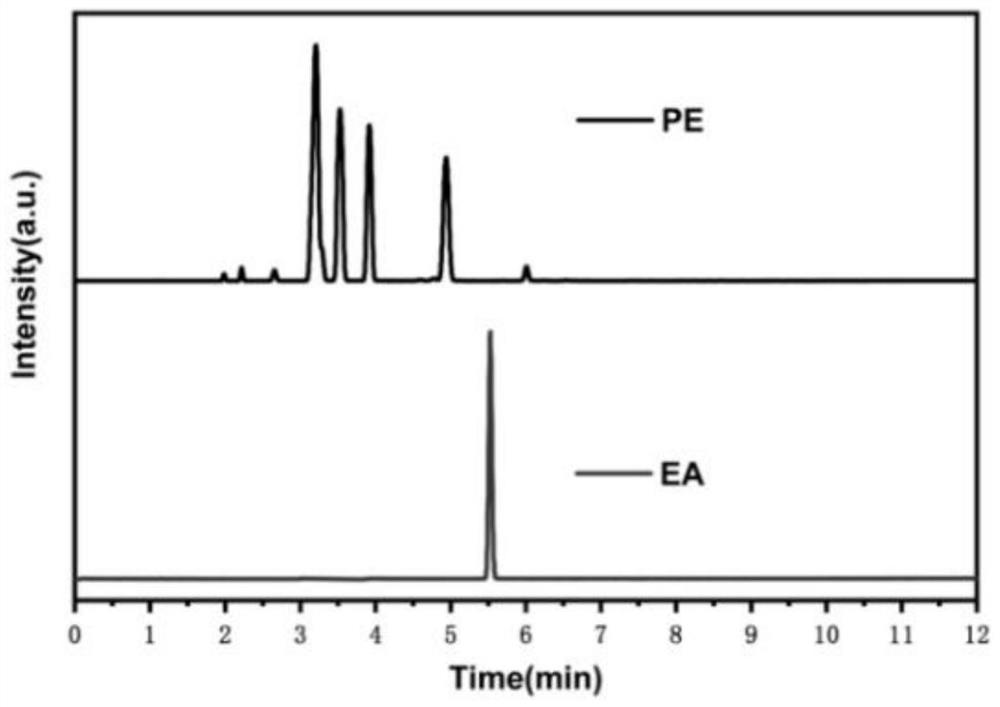

Recovery and analytical test method of ethyl acetate and petroleum ether mixed solvent

A technology of ethyl acetate and mixed solvent, which is applied in the field of recovery and analysis and testing of ethyl acetate and petroleum ether mixed solvent, can solve problems such as difficulty in qualitative analysis, and achieve the effect of good recovery effect and good linear relationship.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] 1. Rotary evaporation and reprocessing to recover the mixed solvent: the mixed solution with a total volume of 60.00 mL was subjected to rotary evaporation at 42°C and a vacuum of 0.09 MPa.

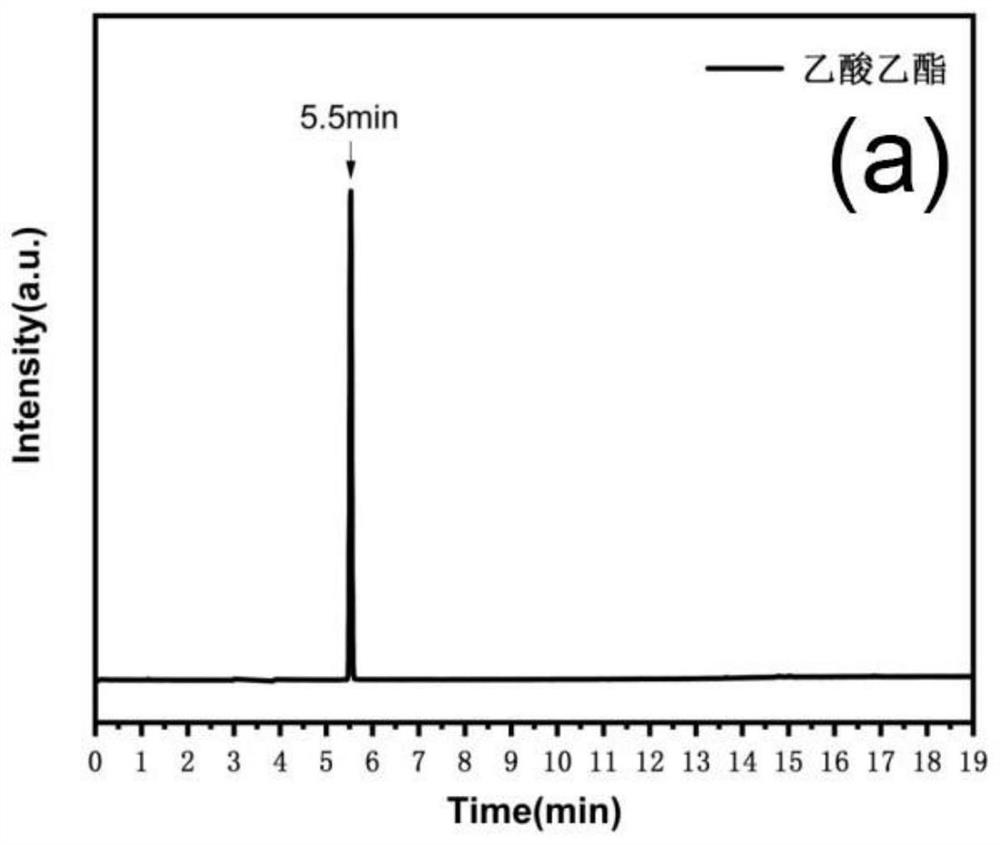

[0055] 2. Use gas chromatography-mass spectrometry for detection, and the gas chromatography and mass spectrometry detection conditions are:

[0056] Gas chromatography conditions:

[0057] Chromatographic column: TG-624 chromatographic column (30m×0.32mm×1.8μm);

[0058] Programmed temperature rise: initial temperature 40°C, keep for 5 minutes, increase to 220°C at 20°C / min and keep for 5 minutes;

[0059] Carrier gas: helium (purity ≥ 99.999%), flow rate: 1.5mL / min;

[0060] Inlet temperature: 230°C

[0061] Injection volume: 1μL, split ratio: 60:1

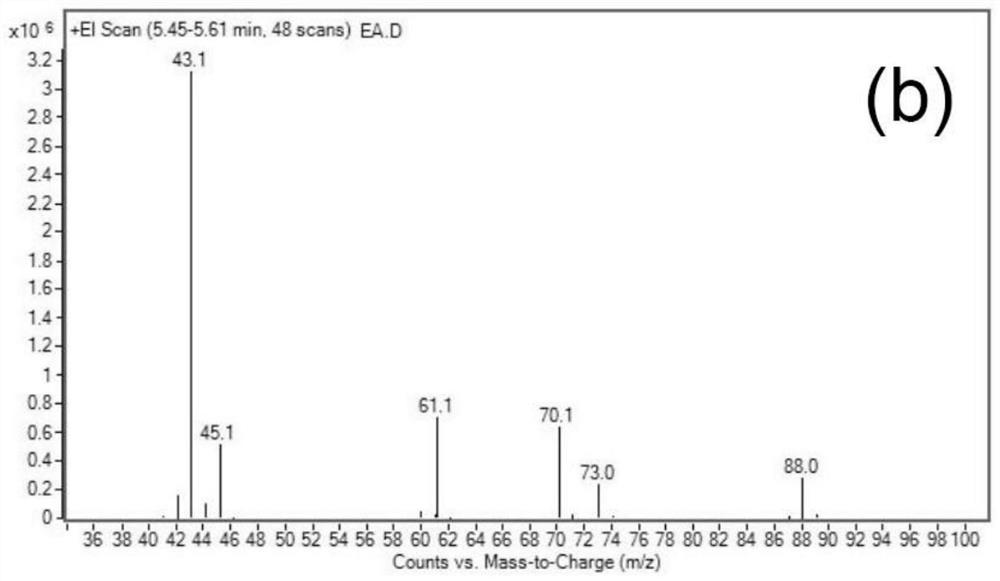

[0062] Mass Spectrometry Conditions:

[0063] Electron bombardment ion source (EI);

[0064] Ion source temperature: 230°C;

[0065] Chromatography mass spectrometer transfer rod temperature: 250°C;

[0066] Mass scanning range...

Embodiment 2

[0091] 1. Rotary evaporation recovery mixed solvent: as in Example 1.

[0092] 2. Detection by gas chromatography-mass spectrometry, as in Example 1.

[0093] 3. Selection of quantitative objects and methods: as in Example 1.

[0094] 4. Setting of MRM measurement method: as in Example 1.

[0095] 5. Draw a standard curve: as in Example 1.

[0096] 6. Preparation and rotary evaporation of mixed solvent of pure ethyl acetate and sherwood oil for analysis: as in Example 1.

[0097] 7. Quantitative analysis of samples by external standard method: according to the above detection conditions, the mixed solvent before and after the rotary evaporation obtained in the above steps was taken for sample injection, and the peak area obtained was substituted into the standard curve equation in Example 1 to calculate the volume percentage of ethyl acetate. The result See Table 6, the results show that there is no significant change in the content of ethyl acetate before and after the rot...

Embodiment 3

[0107] 1. The mixed solvent of ethyl acetate and sherwood oil is recovered by rotary evaporation: as in Example 1.

[0108] 2. Detection by gas chromatography-mass spectrometry, as in Example 1.

[0109] 3. Selection of quantitative objects and methods: as in Example 1.

[0110] 4. Setting of MRM measurement method: as in Example 1.

[0111] 5. Draw a standard curve: as in Example 1.

[0112] 6. Preparation and rotary evaporation of mixed solvent of pure ethyl acetate and sherwood oil for analysis: as in Example 1.

[0113] 7. Quantitative analysis of samples by external standard method: according to the above detection conditions, the sample injection of the mixed solvent before and after the rotary evaporation obtained in the above steps is taken, and the obtained peak area is substituted into the standard curve equation in Example 1 to calculate the volume percentage of ethyl acetate. The results are shown in Table 8, and the results show that there is no significant cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com