High-performance carbon negative electrode PTCDA hard carbon material and preparation method thereof

A carbon negative electrode, high-performance technology, applied in the direction of carbon preparation/purification, negative electrode, active material electrode, etc., can solve the problems of limited application, increase of lithium ion diffusion resistance, poor rate performance of layered graphite negative electrode, etc., to achieve preparation The method is simple, easy for industrial production, and the effect of low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

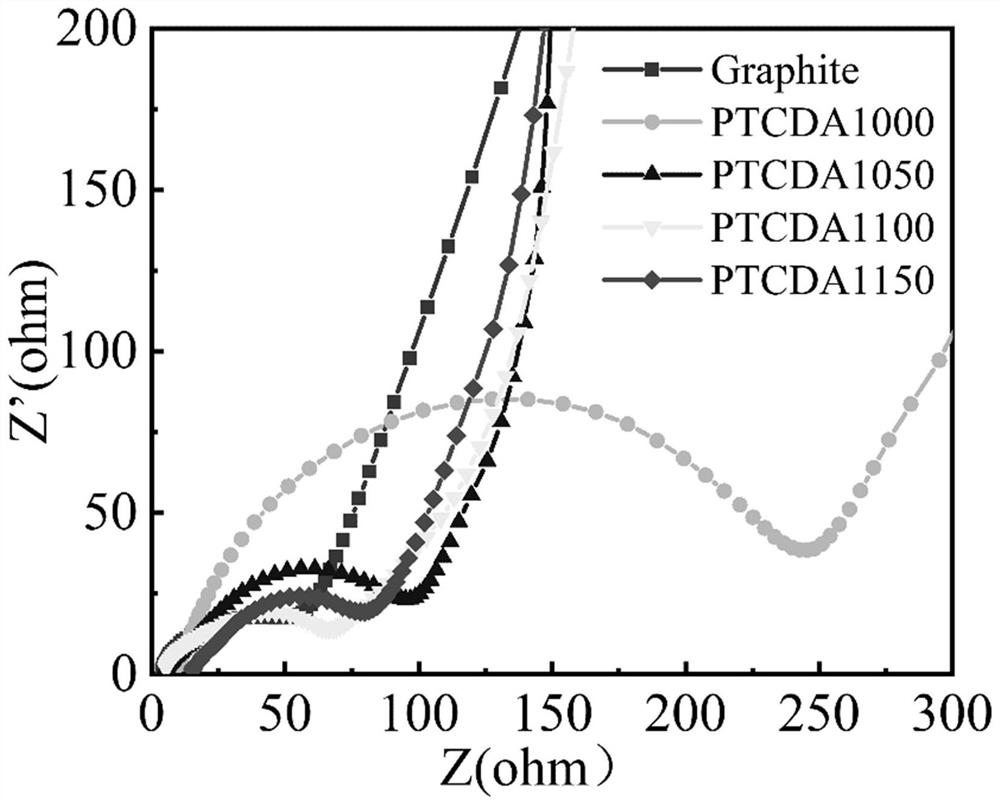

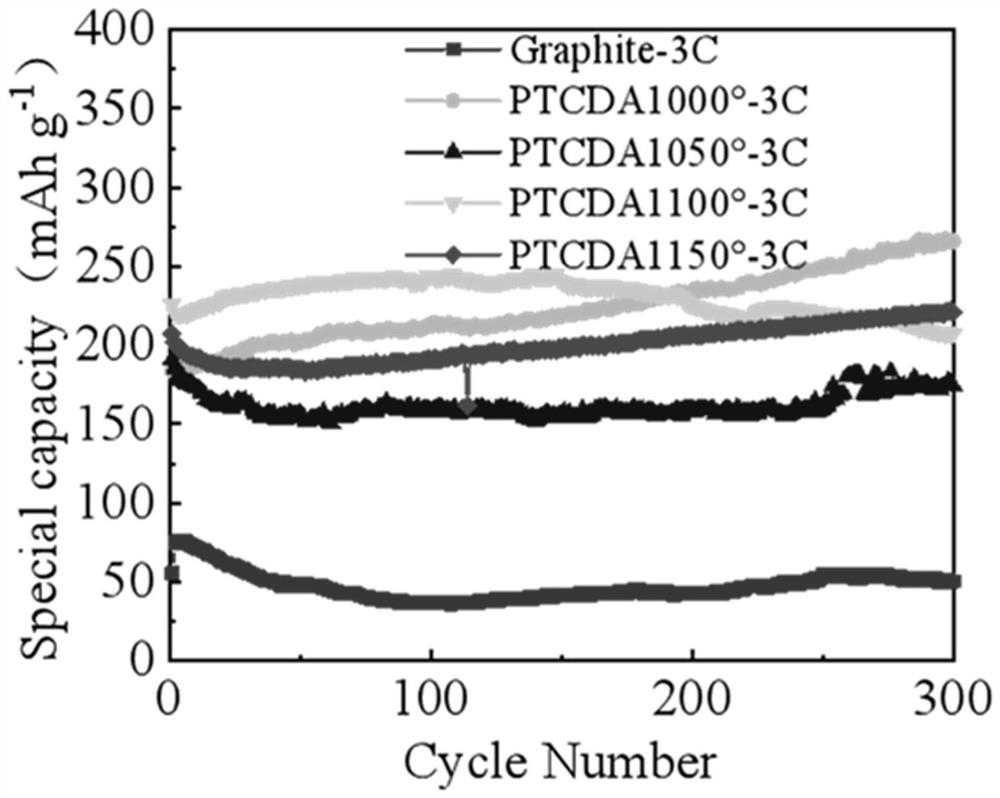

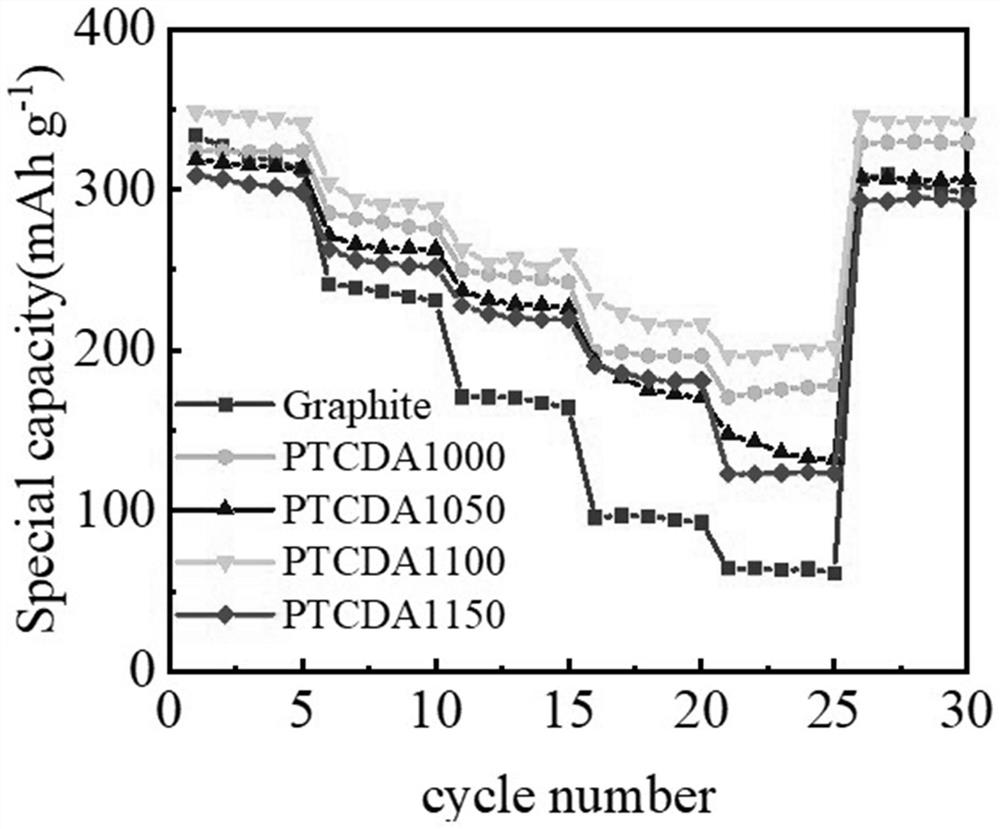

Embodiment 1

[0024] Step 1: Dissolve about 20g of perylenetetracarboxylic dianhydride in a porcelain boat with enough NMP (add in several times), cover the porcelain boat and put it in an oven at 100°C for 24h-48h.

[0025] In step 2, heat at a room temperature of 30° C. at a rate of 3° C. / min to 530° C. over 167 minutes, and keep the temperature for 2 hours.

[0026] Step 3, carbonization: reach 1000°C at a rate of 2°C / min, keep the temperature for 2 hours, and cool down to room temperature as the negative electrode material of perylenetetracarboxylic dianhydride.

[0027] In step 4, the obtained perylene tetracarboxylic dianhydride negative electrode material is ground and passed through a 300-mesh sieve to obtain an extremely fine perylene tetracarboxylic dianhydride negative electrode material.

Embodiment 2

[0029] Step 1: Dissolve about 20g of perylenetetracarboxylic dianhydride in a porcelain boat with enough NMP (add in several times), cover the porcelain boat and put it in an oven at 100°C for 24h-48h.

[0030] In step 2, heat at a room temperature of 30° C. at a rate of 3° C. / min to 530° C. over 167 minutes, and keep the temperature for 2 hours.

[0031] Step 3, carbonization: reach 1050°C at a rate of 2°C / min, keep the temperature for 2 hours, and cool down to room temperature as the negative electrode material of perylenetetracarboxylic dianhydride.

[0032] In step 4, the obtained perylene tetracarboxylic dianhydride negative electrode material is ground and passed through a 300-mesh sieve to obtain an extremely fine perylene tetracarboxylic dianhydride negative electrode material.

Embodiment 3

[0034] Step 1: Dissolve about 20g of perylenetetracarboxylic dianhydride in a porcelain boat with enough NMP (add in several times), cover the porcelain boat and put it in an oven at 100°C for 24h-48h.

[0035] In step 2, heat at a room temperature of 30° C. at a rate of 3° C. / min to 530° C. over 167 minutes, and keep the temperature for 2 hours.

[0036] Step 3, carbonization: reach 1100°C at a rate of 2°C / min, keep the temperature for 2 hours, and cool down to room temperature as the negative electrode material of perylenetetracarboxylic dianhydride.

[0037] In step 4, the obtained perylene tetracarboxylic dianhydride negative electrode material is ground and passed through a 300-mesh sieve to obtain an extremely fine perylene tetracarboxylic dianhydride negative electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com