Inorganic membrane catalyst and preparation method and application thereof

An inorganic membrane and catalyst technology, applied in the preparation of organic compounds, the preparation of amino compounds, chemical instruments and methods, etc., can solve the problems of low efficiency and conversion rate, difficult separation of products and catalyst impurities, and achieve uniform loading and strong acidity. , the effect of rapid coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

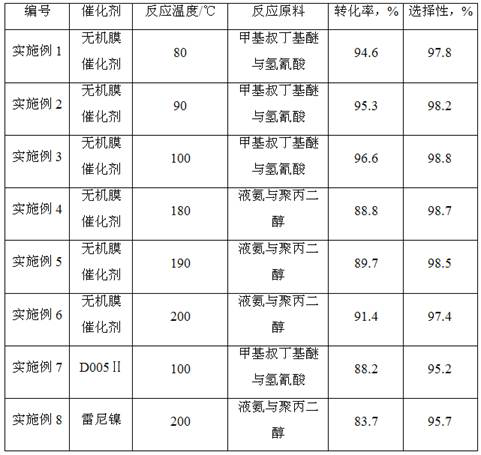

Examples

preparation example Construction

[0030] The following specifically introduces the preparation process of the inorganic membrane catalyst of the present invention: one, 200~250g zirconium n-butoxide (Zr(OBui) 4 ) was dissolved in 250mL ethanol to prepare a zirconium n-butoxide ethanol solution with a molar concentration of 2-4mol / L. Two, be that the nitric acid aqueous solution of 5~8mol / L is added dropwise the zirconium n-butoxide ethanolic solution that step one obtains with molar concentration, obtain transparent sol, then add polyvinyl alcohol and polyethylene glycol of 4~8g respectively, continue to stir, A sol with a certain viscosity is further obtained. Third, the α-Al 2 o 3 Immerse the ceramic tube vertically into the sol obtained in step 2 for 1 to 2 minutes, then pull it out at a pulling speed of 10 to 15 cm / min, then heat-treat it at 100°C for 5 to 10 minutes, repeat the above dipping and pulling and heat treatment for 3 to 5 times, and then calcined at 1000 to 1200° C. for 3 to 6 hours. 4. Seq...

Embodiment 1

[0034] In this example, an inorganic membrane catalyst was prepared and applied to the amination reaction of methyl tert-butyl ether and hydrocyanic acid to prepare tert-butylamine:

[0035] Preparation of inorganic membrane catalysts:

[0036] (1) Dissolve 200 grams of zirconium n-butoxide in 250 mL of ethanol to prepare a solution of zirconium n-butoxide in ethanol, and add an aqueous solution of nitric acid with a molar concentration of 5 mol / L to the above solution dropwise to obtain a transparent sol, and then add 5 g of Continue to stir polyvinyl alcohol and 4g polyethylene glycol to further obtain a sol with a certain viscosity, the stirring temperature is 40°C, and the stirring speed is 200r / min;

[0037] (2) Add α-Al 2 o 3 Immerse the ceramic tube vertically into the sol obtained in step (1) for 2 minutes, pull it out at a pulling speed of 10cm / min, and then heat-treat it at 100°C for 10 minutes, repeat the above steps of dipping, pulling and heat treatment 5 times...

Embodiment 2

[0042] In this example, an inorganic membrane catalyst was prepared and applied to the amination reaction of methyl tert-butyl ether and hydrocyanic acid to prepare tert-butylamine:

[0043] Preparation of inorganic membrane catalysts:

[0044] (1) Dissolve 200 grams of zirconium n-butoxide in 250 mL of ethanol to prepare a solution of zirconium n-butoxide in ethanol; add an aqueous solution of nitric acid with a molar concentration of 6 mol / L to the above solution dropwise to obtain a transparent sol, and then add 5 g of Continue stirring polyvinyl alcohol and 5g polyethylene glycol to further obtain a sol with a certain viscosity, the stirring temperature is 40°C, and the stirring speed is 200r / min;

[0045] (2) Add α-Al 2 o 3 Immerse the ceramic tube vertically into the sol obtained in step (1) for 1 minute, pull it out at a pulling speed of 13 cm / min, and then heat-treat it at 100°C for 8 minutes, repeat the above steps of dipping, pulling and heat treatment 5 times, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com