Hydro-upgrading catalyst as well as preparation method and application thereof

A hydrogenation modification and catalyst technology, applied in the field of catalysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

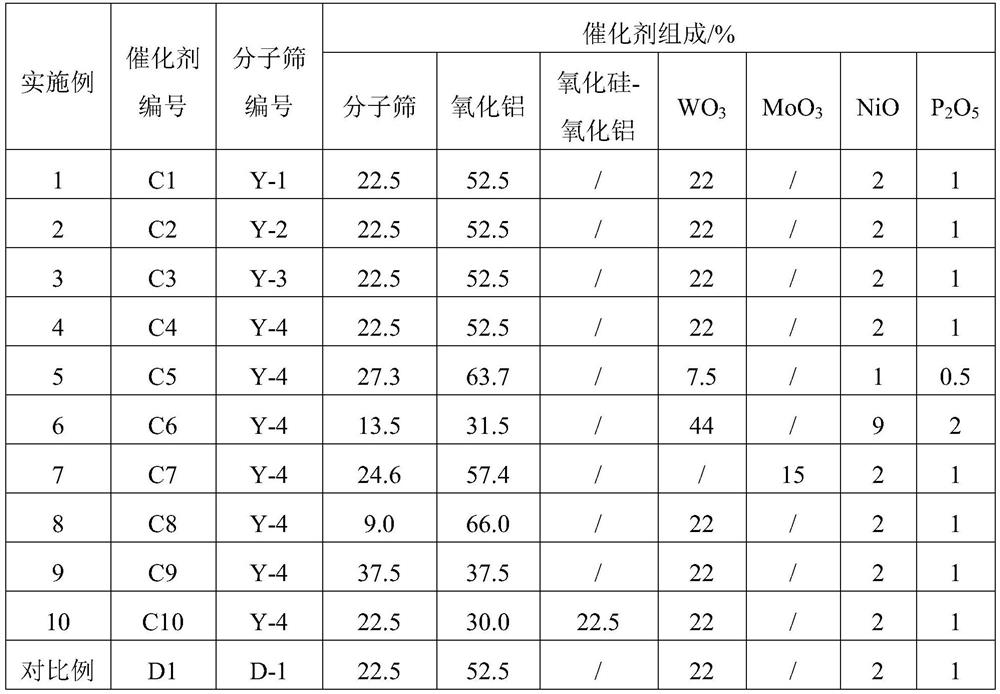

Examples

preparation example Construction

[0060] Specifically, the preparation method of Y molecular sieve of the present invention may comprise the following steps:

[0061] Mix NaY molecular sieve with ammonium salt and water for the first ammonium exchange treatment to obtain the first ammonium exchange molecular sieve;

[0062] The first ammonium-exchanged molecular sieve is subjected to the first hydrothermal roasting treatment in a water vapor atmosphere to obtain the first water-baked molecular sieve;

[0063] mixing the first water-baked molecular sieve with water and adding the first dealumination agent to carry out the first dealumination treatment to obtain the first dealumination molecular sieve;

[0064] The first dealuminated molecular sieve is subjected to a second hydrothermal roasting treatment in a water vapor atmosphere to obtain a second hydrobaked molecular sieve;

[0065] mixing the second water-baked molecular sieve with water and adding a second dealumination agent for second dealumination tre...

Embodiment

[0092] Reagents, Instruments and Tests

[0093] In the following examples, preparation examples and comparative examples, the raw material specifications used are as follows:

[0094] NaY molecular sieve, industrial product, silicon-aluminum ratio > 4.7, crystallinity > 85%

[0095] Sulfuric acid, chemically pure

[0096] Hydrochloric acid, chemically pure

[0097] Nitric acid, chemically pure

[0098] Oxalic acid, solid, chemically pure

[0099] Fluorosilicate, technical grade

[0100] Ammonium nitrate, chemically pure

[0101] Ammonium chloride, chemically pure

[0102] Ammonium oxalate, chemically pure

[0103] Ammonium sulfate, chemically pure

[0104] In the following examples, preparation examples and comparative examples, involved instruments and test methods are as follows:

[0105] The unit cell constant is determined by X-ray diffraction (XRD) using RIPP145-90 standard method (see "Petrochemical Analysis Method (RIPP Test Method)", Yang Cuiding, etc., Scienc...

preparation example 1

[0112] The preparation of preparation example 1 molecular sieve Y-1

[0113] (1) Use NaY zeolite as raw material to exchange with ammonium sulfate solution. The treatment conditions are: according to the ratio of NaY molecular sieve (dry basis): ammonium sulfate: water = 1:1.0:10, exchange at 90°C for 2h, filter and pass through Wash with deionized water and dry at 120°C for 4 hours.

[0114] (2) The molecular sieve obtained in the step (1) is subjected to the first hydrothermal calcination treatment, the calcination temperature is 520° C., and the calcination is carried out under 100% water vapor atmosphere for 2 hours.

[0115] (3) Molecular sieve obtained in step (2) is according to the ratio of molecular sieve (dry basis): sulfuric acid: ammonium chloride: water = 1: 0.06: 0.40: 9, first add water to beating the molecular sieve and slowly add concentration of 20% Sulfuric acid, control the dropping time for 30min, raise the temperature, treat at 70°C for 40min, filter, wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com