All-silicon/high-silicon molecular sieve membrane and quick preparation method thereof

A molecular sieve and high silicon technology, which is applied in the field of full silicon/high silicon molecular sieve membrane and its rapid preparation, can solve the problems of low permeability, large mass transfer resistance, and unfavorable commercial application of molecular sieve membrane.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

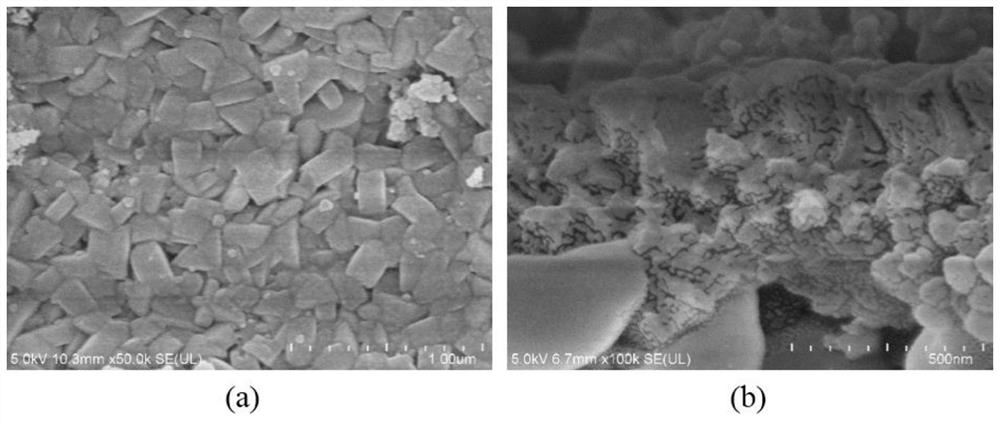

[0063] In this example, an all-silicon MFI molecular sieve membrane was synthesized under mild conditions (synthesized at 100°C for 2 hours). The specific steps are as follows:

[0064] Step 1: Tetrapropylammonium hydroxide was mixed with deionized water, then added tetraethyl orthosilicate (TEOS), stirred for 4 hours to obtain a synthetic liquid for seed crystals, and the molar ratio of the reaction liquid was: 25SiO 2 : 9TPAOH (tetrapropyl ammonium hydroxide): 360H 2 O: 100EtOH, hydrothermal crystallization at 120°C for 24 hours to obtain all-silicon MFI molecular sieve seed crystals (all-silicon MFI molecular sieves can also be called Silicalite-1 molecular sieves), and obtain nano-scale all-silicon MFI molecular sieve molecular sieve crystal seeds after ball milling;

[0065] Step 2: Select a porous ceramic tube with a pore size of 100nm as the carrier, seal the two ends of the carrier with glaze, wash and dry, seal the outer surface with PTFE tape, and brush the nano-scal...

Embodiment 2

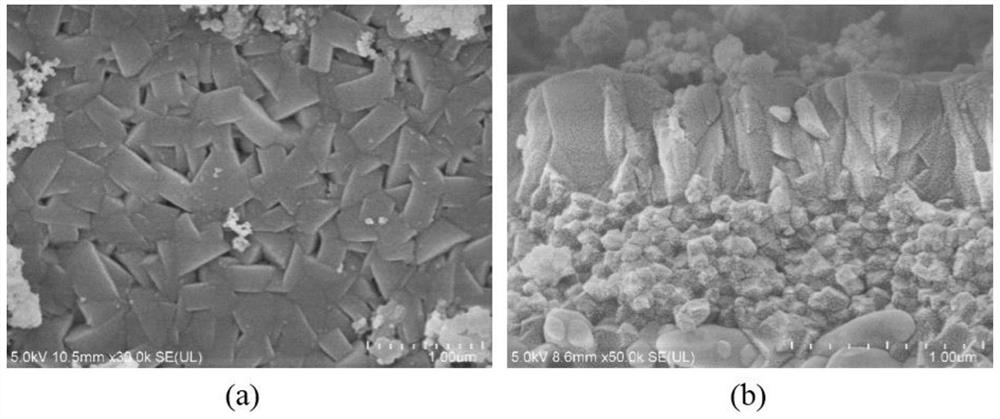

[0075] In this example, an all-silicon MFI molecular sieve membrane was synthesized under mild conditions, and the only difference from Example 1 was that the synthesis time was 4 hours (100 degrees Celsius).

[0076] The surface and profile of gained all-silicon MFI molecular sieve membrane are as follows figure 2 As shown, it can be seen from the figure that the surface of the carrier is completely covered by MFI crystals (typical coffin-shaped crystals), and the cross-linking between crystals is perfect (see figure a); as the synthesis time increases, the thickness of the film increases to 0.65 microns ( See Figure b). It is extremely difficult to prepare an all-silicon MFI molecular sieve membrane with a thickness of less than 1 micron by a simple hydrothermal synthesis method.

[0077] The CO of the membrane tube containing the obtained all-silicon MFI molecular sieve membrane 2 / CH 4 Gas separation test results, at 0.14 MPa, its CO 2 The average permeability of CO...

Embodiment 3

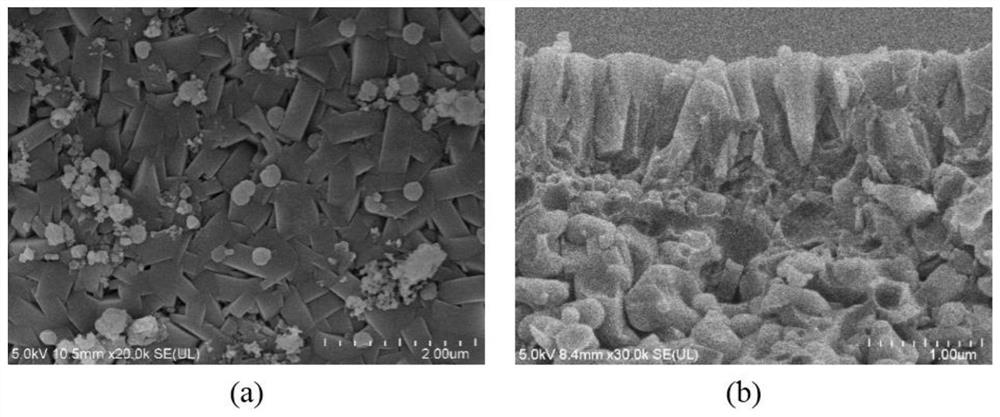

[0079] In this example, an all-silicon MFI molecular sieve membrane is synthesized under mild conditions, the only difference from Example 1 is that the synthesis time is 6 hours (100 degrees Celsius).

[0080] The surface and profile of gained all-silicon MFI molecular sieve membrane are as follows image 3 As shown, it can be seen from the figure that the surface of the carrier is completely covered by MFI crystals (typical coffin-shaped crystals), and the cross-linking between crystals is perfect (see figure a); the thickness of the film is relatively uniform, about 1.03 microns (see figure b) . It is extremely difficult to prepare an all-silicon MFI molecular sieve membrane with a thickness of less than 1 micron by a simple hydrothermal synthesis method.

[0081] The CO of the membrane tube containing the obtained all-silicon MFI molecular sieve membrane 2 / CH 4 Gas separation test results, at 0.14 MPa, its CO2 The average permeability of CO 2 / CH 4 The average sepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com