Enhanced nitrogen and phosphorus removal and resource recycling type constructed wetland system

A constructed wetland system, nitrogen and phosphorus removal technology, applied in the field of enhanced nitrogen and phosphorus removal and resource reuse type constructed wetland system, can solve the problems of complicated manufacturing process, high cost, limited popularization range, etc., to promote nitrification reaction, The effect of large porosity and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

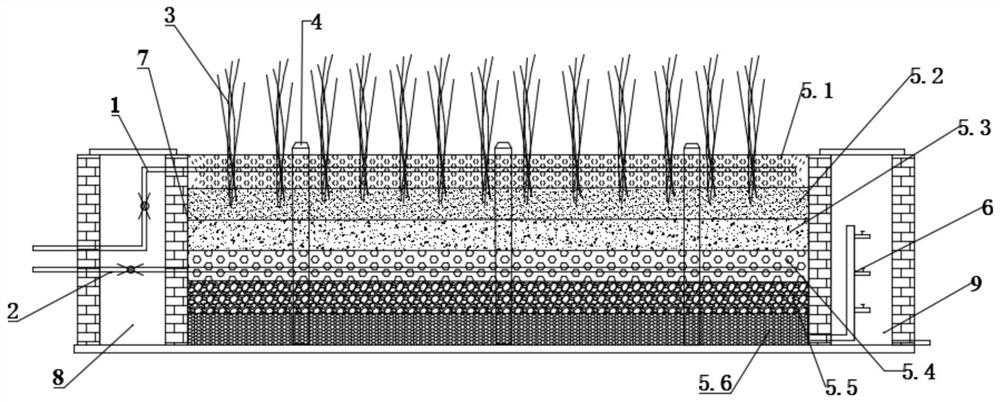

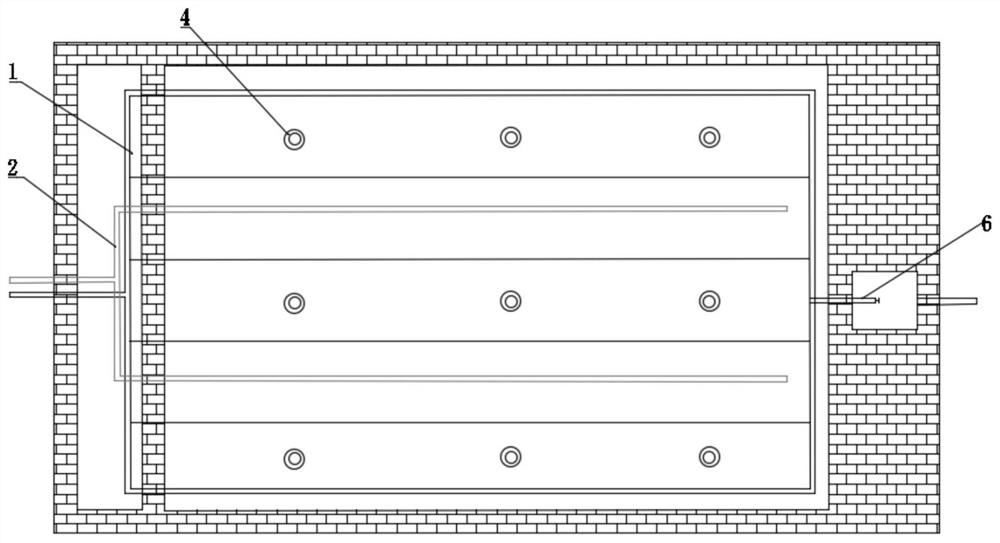

[0034] Such as figure 1 , figure 2 As shown, an enhanced nitrogen and phosphorus removal and resource reuse type constructed wetland system, including a constructed wetland pool 7, a water distribution system 1, an aeration system 2, a ventilation observation well 4, and a nitrogen and phosphorus removal substrate located in the constructed wetland pool And a liquid level control system 6; wetland plants 3 are planted in the nitrogen and phosphorus removal substrate.

[0035] The nitrogen and phosphorus removal matrix includes upper, middle and lower layers, and the height of each filler layer is 20 cm. The upper layer of the denitrification and phosphorus removal matrix is the insulation layer 5.1, and the insulation layer is ceramsite with a particle size between 8 and 32 mm. The middle layer is the natural filler layer, and the lower layer is the construction waste mixed filler layer. Described natural filler layer comprises the first natural filler layer 5.2 of upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com