Zinc aluminate porous carbon-based negative electrode material for lithium ion battery as well as preparation method and application of zinc aluminate porous carbon-based negative electrode material

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low coulombic efficiency, fast capacity decay, and low specific capacity of potassium ion batteries, and achieve high coulombic efficiency and high safety. Sexual, easy to prepare effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

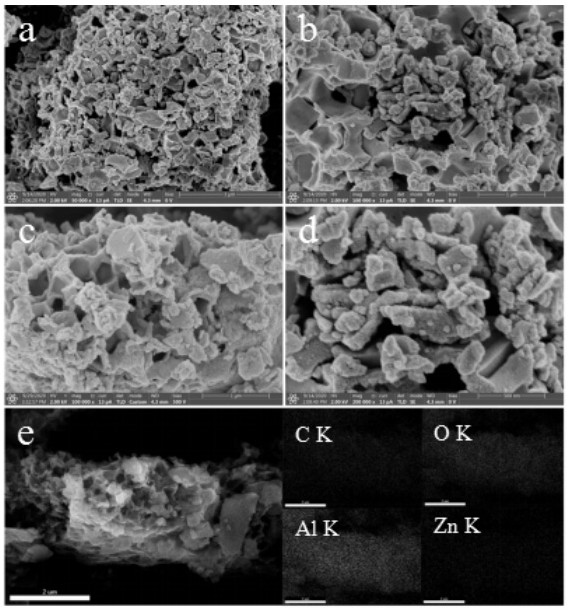

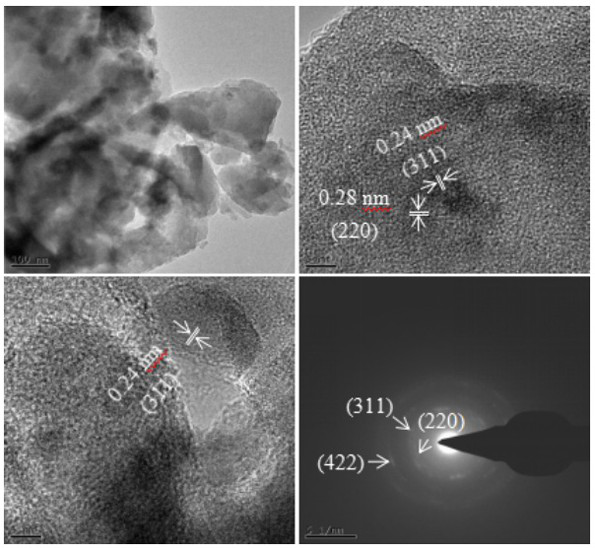

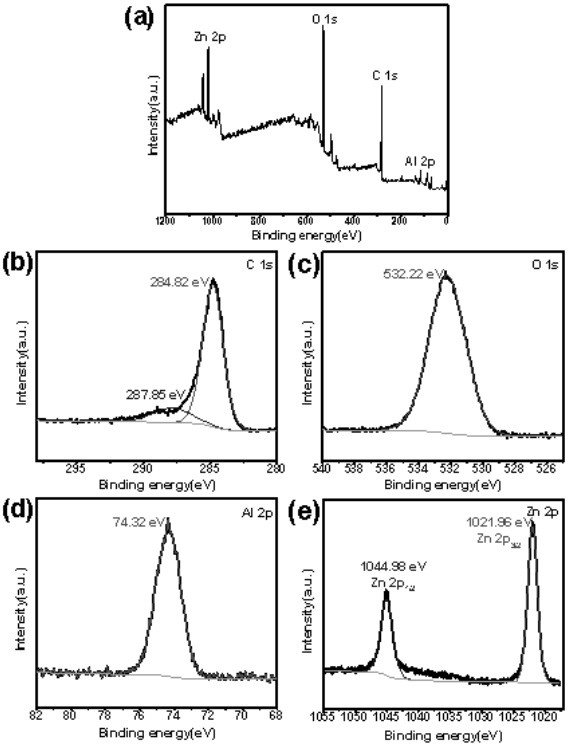

[0033] This example demonstrates a porous structure of ZnAl 2 o 4 / C synthesis method of negative electrode material. ZnAl 2 o 4 The / C negative electrode material is synthesized by preparation and heat treatment at room temperature, including the following steps:

[0034] (1) Pour 2.97 g of zinc nitrate hexahydrate and 2.46 g of 2-methylimidazole into 50 mL of methanol solution, and ultrasonically dissolve them fully. After that, the methanol solution containing 2-methylimidazole was slowly poured into the methanol solution containing zinc nitrate hexahydrate. The resulting mixed solution was stirred at 600 rpm for 24 h at room temperature. Finally, the ZIF-8 white powder was obtained by centrifugation, washed and centrifuged with methanol several times, and dried in an oven at 60 °C.

[0035] (2) Fully dissolve 0.28 g of aluminum trichloride hexahydrate in 20 mL of ultrapure water, then mix with 20 mL of tannic acid solution (10 mg / mL), and stir at room temperature for...

Embodiment 2

[0045] This example demonstrates a porous structure of ZnAl 2 o 4 / C is a lithium-ion battery with a negative electrode.

[0046]The electrode slurry was configured at a ratio of 7:2:1 (sample: conductive carbon black: PVDF (polyvinylidene fluoride)), in which the conductive carbon black was selected as Super P, and the binder was 5% PVDF, that is, 1.0 g of polyvinylidene fluoride The vinyl fluoride powder was fully dissolved in 19.0 g of nitrogen-methylpyrrolidone (NMP) solvent, and then stored in the dark.

[0047] Weigh 70 mg of the sample prepared in Example 1, add about 20 mg of Super P, put it in a mortar, and grind vigorously for 15-20 minutes to make the particle size uniform, mix thoroughly, and then put it in an oven at 60°C to dry ; Then the dried mixed sample is taken out and weighed, according to negative electrode active material: conductive carbon black: binder = 7: 2: 1 ( wt% : wt% : wt% ) mass ratio, drop a certain amount of 5% PVDF, stir in a small we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com