A solvent-free heavy-duty anti-corrosion coating composition capable of wet coating and its preparation method and application

A solvent-free, heavy-duty anti-corrosion technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as 100-500 μm at a time, and multiple constructions to achieve film thickness and VOC. Low content, good construction surface tolerance, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] Another aspect of the embodiments of the present invention also provides a method for preparing the aforementioned wet-appliable solvent-free heavy-duty anti-corrosion coating composition, which includes:

[0082] Mix the composite epoxy resin and reactive diluent evenly, then add thixotropic agent, dispersant, functional filler, pigment and additives and mix evenly to form the first component;

[0083] Mix the cardanol-modified phenalkamine and compound amine curing agent evenly, then add functional additives, accelerators, and non-reactive diluents and mix evenly to form the second component;

[0084] And, uniformly mixing the first component and the second component to form the solvent-free heavy-duty anti-corrosion coating composition capable of wet coating.

[0085] In some more specific embodiments, the preparation method includes:

[0086] Stir and mix the composite epoxy resin and active diluent at a speed of 500-1000r / min, then add the thixotropic agent and st...

Embodiment 1

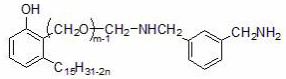

[0112] Stir and mix bisphenol A epoxy resin, bisphenol F epoxy resin, and reactive diluent cardanol glycidyl ether at a speed of 600r / min. Stir at low temperature for 15 minutes, then add dispersant BYK-9076, rutile titanium dioxide, aluminum clay, silicon micropowder, and barium sulfate recrystallization, and stir for 15 minutes at a speed of 1200r / min and a temperature of 57°C, and finally add a wetting Agent YCK-1450, leveling agent YCK-1530, and defoamer BYK-066 are mixed evenly to form the first component; (the content of each component in the first component is shown in Table 1)

[0113] Stir and mix cardanol-modified phenalkamine and complex amine curing agent at a speed of 600r / min, then add defoamer BYK-066 and accelerator K54 and mix evenly, then add inactive diluent to the obtained mixture The cashew nut shell oil polyol is mixed uniformly to form the second component; (wherein the content of each component in the second component is as shown in Table 2)

[0114] M...

Embodiment 2

[0117] Stir and mix bisphenol A epoxy resin, bisphenol F epoxy resin, and reactive diluent cardanol glycidyl ether at a speed of 600r / min. Stir at low temperature for 15 minutes, then add dispersant BYK-9076, rutile titanium dioxide, aluminum clay, silicon micropowder, and barium sulfate recrystallization, and stir for 15 minutes at a speed of 1200r / min and a temperature of 57°C, and finally add a wetting Agent YCK-1450, leveling agent YCK-1530, and defoamer BYK-066 are mixed evenly to form the first component; (the content of each component in the first component is shown in Table 1)

[0118] Stir and mix cardanol-modified phenalkamine and complex amine curing agent at a speed of 600r / min, then add defoamer BYK-066 and accelerator K54 and mix evenly, then add inactive diluent to the obtained mixture The cashew nut shell oil polyol is mixed uniformly to form the second component; (wherein the content of each component in the second component is as shown in Table 2)

[0119] M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com