Microwave pyrolysis comprehensive utilization method for waste computer circuit boards

A circuit board and pyrolysis technology, which is applied in the field of comprehensive utilization of microwave pyrolysis of waste computer circuit boards, can solve the problems of difficult removal of bromine, reduction, and influence of separation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for comprehensive utilization of waste computer circuit boards by microwave pyrolysis, the specific steps are as follows:

[0032] Before pyrolysis, put the circuit board into a high-temperature hot air furnace, raise the temperature to 250°C and keep it warm for 10 minutes, vibrate to recover the solder, and perform detinning pretreatment first. Manually remove the components on the circuit board, and then cut the circuit board to 1cm with a board shear 2of small pieces. Turn on the coolant circulating pump, and set the temperature of the condensed water in the circulating cooling system to -3°C. Put the small pieces of the circuit board into the microwave oven. After checking the airtightness, first pass in nitrogen for 10 minutes to evacuate the air in the pipeline, and then under the microwave intensity of 10g / 1KW, the heating rate is 25°C / min, and the temperature is raised to 400 ℃ pyrolysis 1h, control the nitrogen flow rate 0.1L / min during the pyrolysi...

Embodiment 2

[0034] Embodiment 2 (add carbon powder in the circuit board, other conditions are identical with embodiment 1)

[0035] A method for comprehensive utilization of waste computer circuit boards by microwave pyrolysis, the specific steps are as follows:

[0036] Before pyrolysis, put the circuit board into a high-temperature hot air furnace, raise the temperature to 250°C and keep it warm for 10 minutes, vibrate to recover the solder, and perform detinning pretreatment first. Manually remove the components on the circuit board, and then cut the circuit board to 1cm with a board shear 2 of small pieces. Turn on the coolant circulating pump, and set the temperature of the condensed water in the circulating cooling system to -3°C. Mix the small pieces of the circuit board with 5% coke powder by mass and put them into a microwave oven. After checking the airtightness, first pass in nitrogen for 10 minutes to exhaust the air in the pipeline, and then under the microwave intensity of...

Embodiment 3

[0043] Embodiment 3 (other is identical with embodiment 2, controls different pyrolysis temperature)

[0044] Control other conditions are identical with embodiment 2, only control pyrolysis temperature, obtain under different pyrolysis temperature, the situation of pyrolysis oil composition is as follows.

[0045] Table 2 The influence of pyrolysis temperature on the composition of TXDN liquid product

[0046]

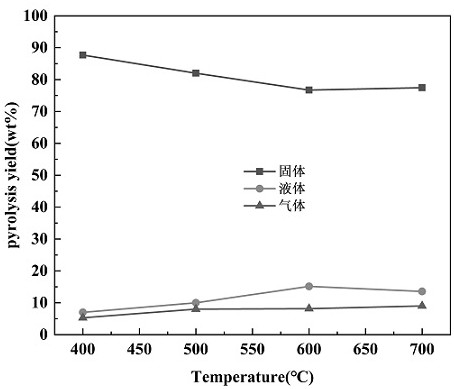

[0047] It can be seen from the figures and tables that as the pyrolysis temperature rises, the solid residue yield decreases, and the liquid yield increases first and then decreases, reaching a maximum value of 15.15% at 600°C; the gas yield gradually increases. In the range of 500-600 ° C, the polymer chains such as epoxy resin contained in the material are heated and broken into long-chain compounds, so the liquid product increases; as the temperature continues to increase, the liquid product is before the volatiles escape the reactor. A secondary decomposition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com