Rice hull silicon slow-release porous material for air purification and preparation method thereof

A technology for air purification, porous materials, applied in the fields of botanical equipment and methods, air quality improvement, chemicals for biological control, etc., can solve the problem of short duration, high concentration of released gas, slow release time and slow release The amount cannot be precisely controlled, etc., to achieve the effects of low cost, prolonged sustained release time, and accurate and controllable sustained release amount and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The present invention provides a technical solution: a rice husk silicon slow-release air-purifying porous material and its preparation method. The specific preparation steps of the rice husk silicon slow-release air-purifying porous material are as follows:

[0023] A, first get a certain equal portion of chlorite and dissolve it in paraffin to obtain a powder mixture, then press it through a powder tablet machine, and form a chlorite reaction layer after tableting;

[0024] B, get a certain equal portion of the acid and dissolve it in paraffin to make a powder mixture, then press it through a powder tablet machine, after the tableting, the acid-containing layer reaction layer is formed;

[0025] C, the chlorite reaction layer obtained in step A, and the acid-containing layer reaction layer obtained in step B, add rice husk silica between them, and then use a powder tablet press to perform tabletting together, and finally form The upper reaction layer is a chlorite rea...

Embodiment 1

[0030] Mix 1g of sodium chlorite and 2g of paraffin wax powder, heat to 65°C, stir to completely dissolve the chlorite in the paraffin wax, and compress the above mixture cooled to room temperature with a powder tablet machine at 2MPa; 0.5g of oxalic acid Mix it with 1g of paraffin wax powder, heat it to 65°C, stir evenly, and compress the mixture of oxalic acid and paraffin wax powder cooled to room temperature with a powder tablet press at 2MPa; Pressing tablets to form a sandwich structure micro-reaction slow-release space purification tablet;

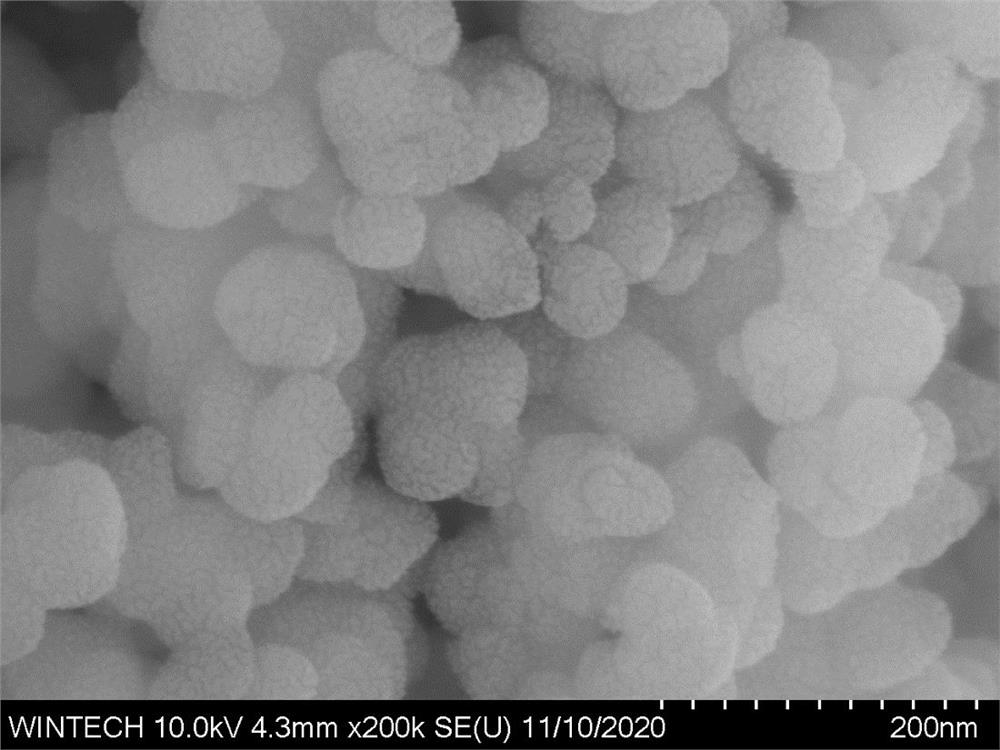

[0031] The microscopic scanning electron microscope picture of rice husk silica is shown in the appendix Figure 1 The particle diameter of nano-silica is about 10-40 nanometers, and the nano-particles are covered with worm-like channels. The pore diameter of the pores is 4 nanometers tested by nitrogen adsorption, and the specific surface area of rice husk silica is about 200m2 / g. The micro-reaction space purification tablet has...

Embodiment 2

[0033] Mix 3g of sodium chlorite and 8g of paraffin wax powder, heat to 65°C, stir to completely dissolve the chlorite in the paraffin wax, and compress the above mixture cooled to room temperature with a powder tablet machine at 9MPa; 2g of citric acid Mix it with 3g of paraffin wax powder and heat it to 65°C, stir evenly, and compress the mixture of oxalic acid and paraffin wax powder cooled to room temperature with a powder tablet press at 9MPa; add 2g of rice husk silica between the above two pieces, together at 9MPa Press into tablets to form a sandwich structure micro-reaction slow-release space purification tablet. The micro-reaction space purification tablet has a sterilization rate of over 99.9% at 25°C, an effective volume of 12 cubic meters, and an effective time of 120 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com