A kind of polyepoxy chain extender and its preparation method and application

A multi-epoxy chain extender and glycidyl ester technology, applied in the field of chain extenders, can solve the problems of large steric hindrance of the benzene ring, material accumulation in the head of a screw machine, and increasing the amount of chain extenders, so as to improve the molecular weight and process performance, avoid gels and build-up, improve the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The second aspect of the present invention provides a method for preparing the polyepoxy chain extender as described above, comprising: mixing the raw materials for the preparation of the polyepoxy chain extender, reacting and drying at 60-100°C to obtain the obtained The polyepoxy chain extender mentioned above.

[0055] In one embodiment, the preparation method of the multi-epoxy chain extender of the present invention includes: after mixing the solvent and the dispersant, heating to 60-100° C. for 0.5-2 hours, adding the initiator, the active monomer react with the mixture of chain transfer agents for 1-32 hours, filter, wash and dry to obtain the polyepoxy chain extender.

[0056] The third aspect of the present invention provides the use of the polyepoxy chain extender as described above for the processing of polymers. The present invention does not specifically limit the polymer, but it is a polymer containing functional groups such as ester groups, hydroxyl grou...

Embodiment 12

[0063] Embodiment 12 also provides the preparation method of the polyepoxy chain extender as described above, including: after mixing the solvent and the dispersant, heating to 75° C. for 1 hour, adding the mixture of the initiator, the active monomer and the chain transfer agent After reacting for 15 hours, bead-shaped solid particles were obtained, which were filtered, washed and dried to obtain the polyepoxy chain extender.

Embodiment 13

[0064] Embodiment 13 also provides the preparation method of the polyepoxy chain extender as described above, including: after mixing the solvent and the dispersant, heating to 75° C. for 1 hour, adding the mixture of the initiator, the active monomer and the chain transfer agent After reacting for 13.5 hours, bead-shaped solid particles were obtained, which were filtered, washed and dried to obtain the polyepoxy chain extender.

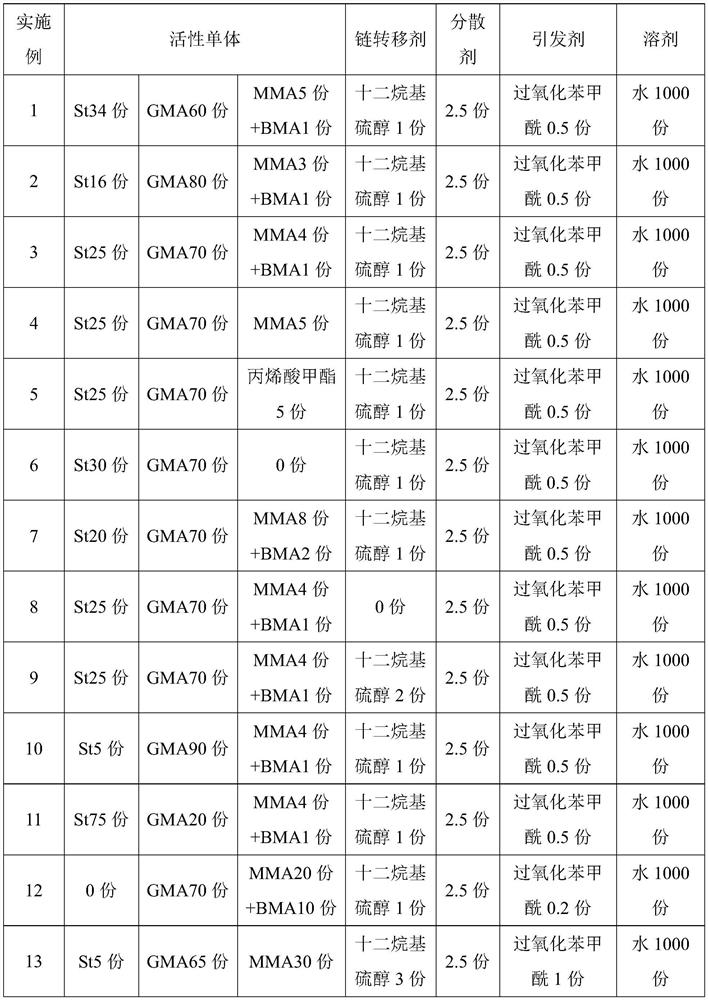

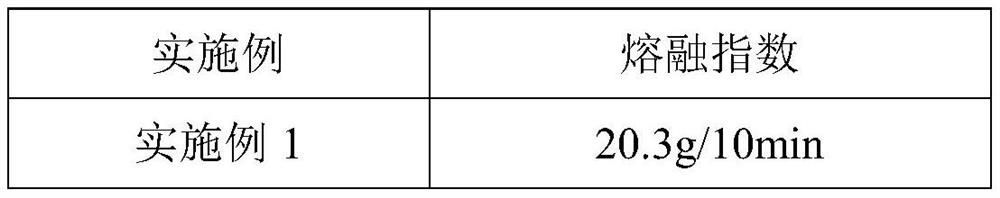

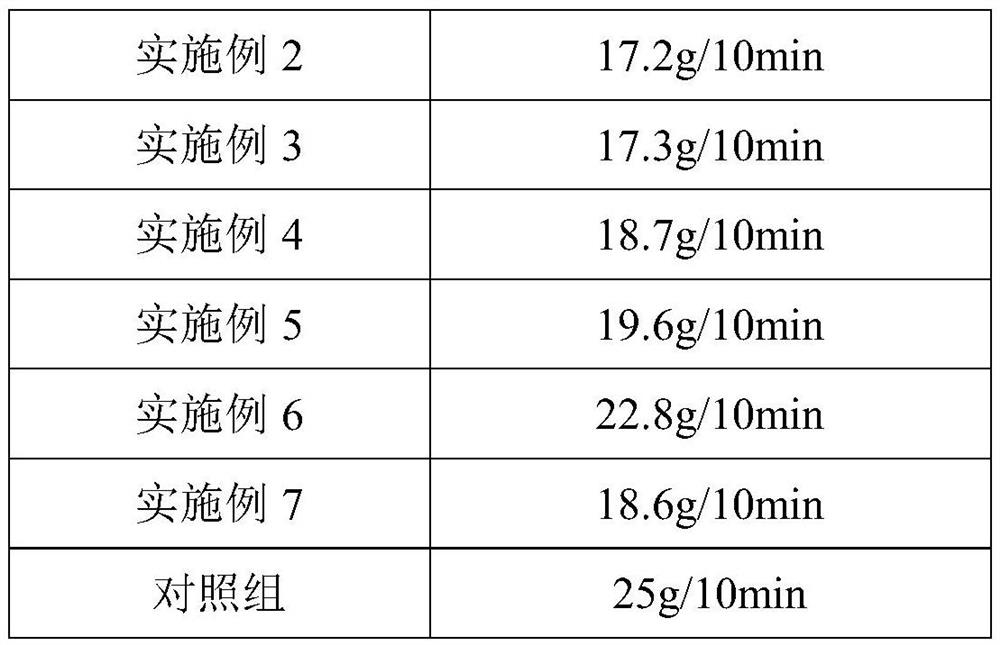

[0065] performance evaluation

[0066] The multi-epoxy chain extenders provided in Examples 1 to 13 were used as the experimental group, and the commercially available KL-E4370 was used as the control group, and PET and PLA were used as polymers for processing respectively. The effect of the composition and molecular weight of the copolymer of the epoxy chain extender on the processability, melt index and mechanical properties of the polymer was tested.

[0067] 1. The influence of the composition of copolymers with high benzene ring content and mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com