Preparation method and application of oil-water non-slip rubber material

A rubber material and anti-slip technology, applied in the field of preparation of oil-water anti-slip rubber materials, can solve the problem of inability to take into account the balance of oil resistance, anti-slip and wear resistance, poor performance of composite materials, and inability to meet the needs of sports products, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

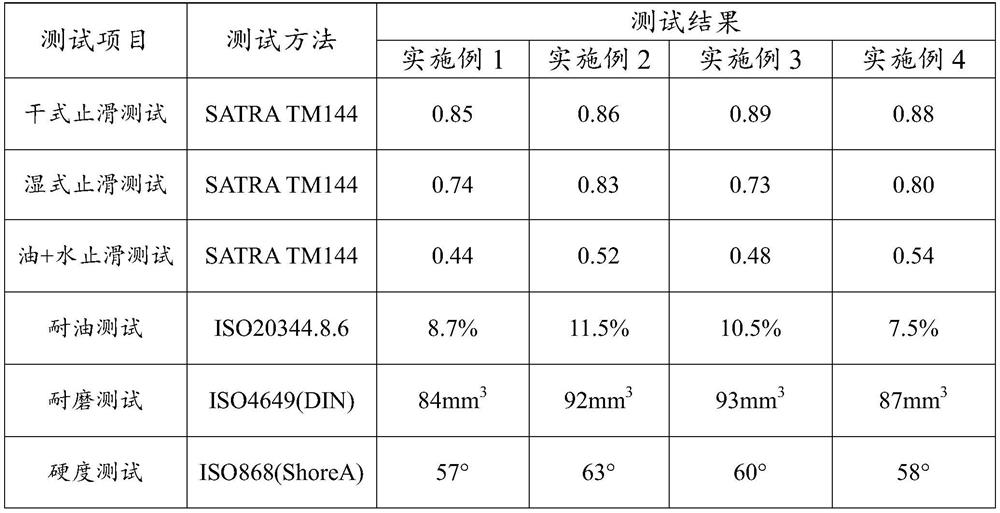

Examples

Embodiment 1

[0026] The preparation method steps of oil-water anti-slip rubber material are as follows:

[0027] S1: Mix 15 parts of butadiene rubber, 35 parts of nitrile rubber, 1 part of stearic acid, 1.5 parts of anti-aging agent, 2.5 parts of white smoke active agent, 1.5 parts of accelerator and 7.5 parts of resin in the internal mixer to 135 After unloading at ℃, cool in water, store and mature to obtain the first rubber material;

[0028] S2: Refining the first rubber material by means of an open mill, adding 4 parts of silane coupling agent and 1.5 parts of sulfur, making several triangular bags, pulling 1.5mm thinner and dispersing once, cooling the sheet to obtain the second rubber material ;

[0029] S3: test vulcanization time, quality inspection second rubber material;

[0030] S4: heating and vulcanizing the second rubber material under the conditions of temperature of 160° C. and pressure of 140 MPa, and molding time of 10 to 20 minutes to obtain an oil-water anti-slip rub...

Embodiment 2

[0032] The preparation method step of modified nitrile rubber is as follows:

[0033] Put zinc oxide and white carbon black into a beaker, add distilled water, stir slowly at a constant temperature of 60°C, add nitrile rubber during the stirring process, increase the stirring rate, continue stirring for 0.5h until fully mixed, and stir Slowly add the template agent dropwise during the process. After the template agent is added dropwise, continue to stir for 1 hour, pour the mixed solution into the crystallization axe, put the crystallization axe in an oven at 200°C for crystallization reaction for 48 hours, take it out, and cool to room temperature Finally, filter with suction and dry in an oven at 100°C to obtain modified nitrile rubber.

[0034] The preparation method steps of oil-water anti-slip rubber material are as follows:

[0035] S1: Mix 15 parts of butadiene rubber, 35 parts of modified nitrile rubber, 1 part of stearic acid, 1.5 parts of anti-aging agent, 2.5 parts...

Embodiment 3

[0040] The preparation method steps of oil-water anti-slip rubber material are as follows:

[0041] S1: Mix 10 parts of butadiene rubber, 30 parts of modified nitrile rubber, 1 part of stearic acid, 1 part of anti-aging agent, 2 parts of white smoke active agent, 1 part of accelerator and 5 parts of resin in an internal mixer Unload after reaching 135°C, cool with water, store and mature to obtain the first rubber material;

[0042]S2: Refining the first rubber material by means of an open mill, adding 3 parts of silane coupling agent and 1 part of sulfur, making several triangle bags, stretching 1.5mm thinner and dispersing once, cooling the sheet to obtain the second rubber material ;

[0043] S3: test vulcanization time, quality inspection second rubber material;

[0044] S4: heating and vulcanizing the second rubber material under the conditions of temperature of 160° C. and pressure of 140 MPa, and molding time of 10 to 20 minutes to obtain an oil-water anti-slip rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com