Multifunctional composite melt-blown non-woven fabric and preparation method thereof

A melt-blown non-woven fabric, multi-functional technology, applied in the direction of non-woven fabrics, textiles and papermaking, single-component synthetic polymer rayon, etc., can solve the need to improve the filtration efficiency, poor electret effect and charge stability And other problems, to achieve the effect of improving the electret effect and charge stability, good electrostatic electret effect, and low piezoresistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A preparation method of the above-mentioned multifunctional composite melt-blown nonwoven fabric, comprising the following steps:

[0032] S1. Weigh polypropylene, initiator and fluorine-containing olefin monomer according to the mass ratio of 100:(0.5~10):(2~20), mix them uniformly, and then melt blend them in a twin-screw extruder to modify properties, to obtain fluorine-containing graft modified polypropylene melt-blown material; the initiator is one of dicumyl peroxide, benzoyl peroxide, and di-tert-butyl peroxide;

[0033] S2. Melt and mix polypropylene in a twin-screw extruder to obtain polypropylene melt-blown material;

[0034] S3. Perform double-layer melt blown on the fluorine-containing graft modified polypropylene melt blown material obtained in step S1 and the polypropylene melt blown material obtained in step S2 to obtain the multifunctional composite melt blown nonwoven fabric.

[0035]In the present invention, polypropylene is selected as the matrix mat...

Embodiment 1

[0041] A kind of multifunctional composite melt-blown non-woven fabric, is prepared through the following steps:

[0042] S1. Weigh polypropylene, benzoyl peroxide and trifluoroethyl methacrylate with a melt index of 1400g / 10min according to a mass ratio of 100:2:10, mix them uniformly, and melt them in a twin-screw extruder Blending modification (processing temperature is 180°C) to obtain fluorine-containing graft modified polypropylene melt-blown material;

[0043] S2. melting and mixing polypropylene with a melt index of 1150g / 10min in a twin-screw extruder to obtain a polypropylene melt-blown material (the melt index of the polypropylene melt-blown material is 1000g / 10min);

[0044] S3. The fluorine-containing graft modified polypropylene melt-blown material obtained in step S1 and the polypropylene melt-blown material obtained in step S2 are subjected to double-layer MM melt-blown to obtain the multifunctional composite melt-blown non-woven fabric .

[0045] Electret ch...

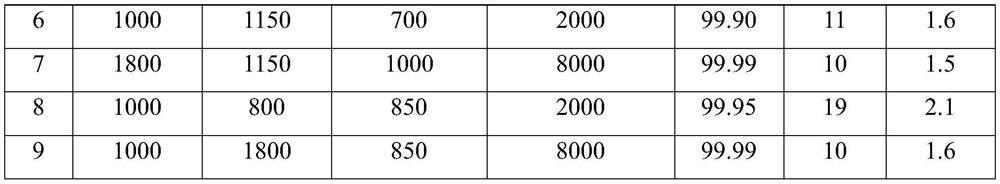

Embodiment 2-5

[0050] A kind of multifunctional composite melt-blown non-woven fabric, compared with Example 1, the difference is that in step S1, the quality ratio of polypropylene, benzoyl peroxide and trifluoroethyl methacrylate is as shown in Table 1 . Others are substantially the same as in Embodiment 1, and will not be repeated here.

[0051] Preparation conditions and filtration performance of table 1 embodiment 2-5

[0052]

[0053] As can be seen from Table 1, in Examples 2 and 3, under the same conditions of initiator content, with the increase of the content of trifluoroethyl methacrylate, the higher the surface electrostatic potential of polypropylene, the better the filtering effect of PM2.5 The better, the lower the filter piezoresistance and the smaller the rate of charge decay. Examples 4 and 5, under the same conditions of the content of functional monomer trifluoroethyl methacrylate, as the content of the initiator DCP increases, the surface electrostatic potential of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com