Lithium niobate coated and niobium doped coupled modified high-nickel ternary positive electrode material as well as preparation method and application of lithium niobate coated and niobium doped coupled modified high-nickel ternary positive electrode material

A high-nickel ternary material and cathode material technology, applied in the direction of positive electrodes, active material electrodes, electrical components, etc., can solve the problems of poor rate performance, poor cycle stability, etc., and achieve good stability, inhibit phase transition, and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

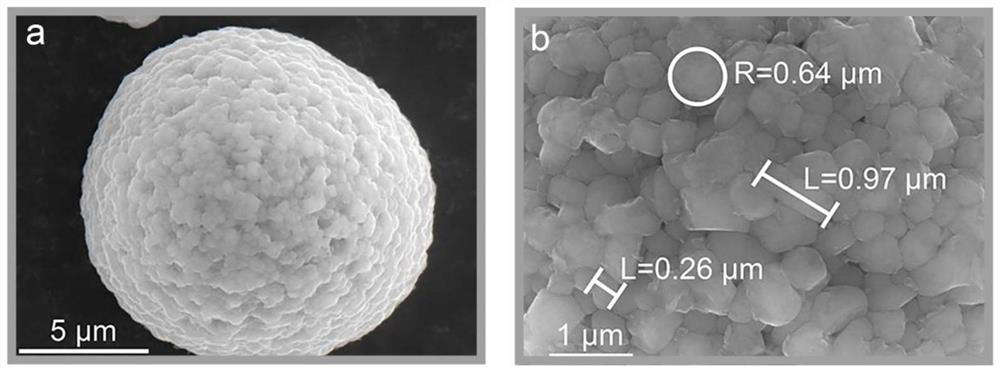

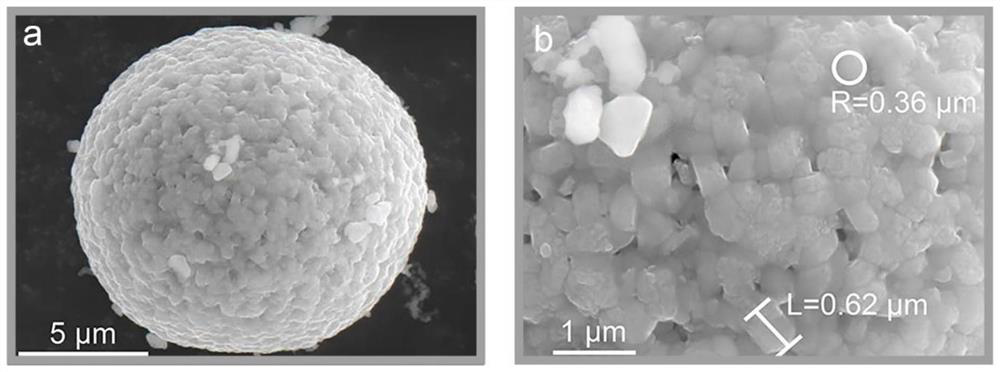

[0040] Take commercially available high-nickel ternary cathode material, the chemical formula is LiNi 0.88 Co 0.10 Mn 0.02 O 2 , named NCM88. It was detected by scanning electron microscope, and the detection results were as follows figure 1 As shown, the positive electrode material is a secondary particle composed of agglomeration of primary nanoparticles, with a particle size of about 5 μm, and the primary nanoparticles are already about 500 nm.

[0041] The high-nickel ternary positive electrode material used in the following examples is the high-nickel ternary positive electrode material NCM88 of this embodiment.

Embodiment 2

[0043] A preparation method of a high-nickel ternary positive electrode material with lithium niobate coating and niobium doping coupling modification, comprising the following steps:

[0044] S1, take 20.5126mg of niobium oxalate ammonia C 4 H4 NNbO 9 ·nH 2 , 2.8665mg of lithium hydroxide LiOH·H 2 O; Add ammonium niobium oxalate and lithium hydroxide to 30ml of anhydrous ethanol solution respectively, stir in oil bath at 35°C and rotate at 400rpm until completely dissolved to form solution A and solution B respectively; mix solution A and solution B, oil bath Heated to 45°C, stirred for 1 h, and the stirring speed was 1000 mg of high nickel ternary material (LiNi 0.88 Co 0.10 Mn 0.02 O 2 ), heated and stirred in an oil bath at a temperature of 50 ° C, the stirring speed was 400 rpm, and stirred for 2 hours; then the temperature was raised to 75 ° C and continued to be heated and stirred in an oil bath, and the stirring speed was 400 rpm, until the solution remained a li...

Embodiment 3

[0047] A preparation method of a high-nickel ternary positive electrode material with lithium niobate coating and niobium doping coupling modification, comprising the following steps:

[0048] S1, take 61.5375mg of niobium oxalate ammonia C 4 H 4 NNbO 9 ·nH 2 , 8.5995mg of lithium hydroxide LiOH·H 2 O, add 30ml of absolute ethanol respectively, heat the oil bath to 35°C, and stir until completely dissolved under the condition that the rotating speed is 400rpm to obtain solution A and solution B; mix the two solutions, heat the oil bath to 45°C, stir For 1 hour, the stirring speed was 400 rpm; then 1000 mg of high-nickel ternary material was added, and the oil bath was heated to 50 °C for 2 hours, and the stirring speed was 400 rpm; then the oil bath was heated to 75 °C, and the stirring speed was 400 rpm. , until the solution remains a little, stop stirring and heating, and use the residual heat to evaporate to dryness to obtain the precursor powder;

[0049] S2. Take the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com