Tar reduction type cigarette paper and preparation method thereof

A technology for cigarette paper and coke reduction, applied in special paper, paper, papermaking and other directions, can solve the problems of lowering, lowering and unfavorable tar content in cigarette smoke, and achieves reducing tar amount, increasing air permeability and reducing temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

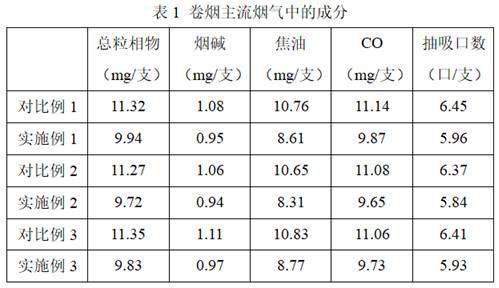

Examples

preparation example Construction

[0041] The embodiment of the present invention also provides a method for preparing a reduced-coke cigarette paper, comprising the following steps:

[0042] (1) Add fillers and combustion regulators after dispersing the papermaking fibers, mix and beat to form a slurry;

[0043] (2) The pulp is dehydrated, formed, pressed, and copied in sequence to form a wet paper base;

[0044] (3) Prepare an adhesive solution containing modified thermally conductive activated carbon, potassium chlorate and catalyst;

[0045] (4) The adhesive solution is evenly added to the surface of the wet paper base by sizing to form an adhesive layer, and the cigarette paper is obtained by drying, curling, and cutting; wherein, the specific surface area of the modified thermally conductive activated carbon is 900~1000m 2 / g, the thermal conductivity is 5~8w / (m×K); the catalyst is manganese dioxide or copper oxide. Preferably, the added amount of modified heat-conducting activated carbon accounts for...

Embodiment 1

[0051] Embodiment 1 of the present invention provides a kind of reduced tar type cigarette paper and its preparation method, and this reduced tar type cigarette paper is prepared according to the following method:

[0052] (1) Preparation of modified thermally conductive activated carbon:

[0053] (10) Immerse 200-mesh walnut shell powder into 0.3g / mL zinc chloride solution, the mass ratio of walnut shell powder and zinc chloride in the mixed solution is 1: 0.8, and then react in a water bath at 80°C for 3 hours, and the dipped The solid powder was dried in a vacuum oven at 120°C for 12 hours;

[0054] (20) Add 30% of 80-mesh expanded graphite to the dried solid powder and mix evenly, and press the mixture under 8MPa pressure;

[0055] (30) Carbonize the pressed mixture in an inert atmosphere at 580°C for 5 hours;

[0056] (40) Wash the carbonized product to neutrality and dry at 120°C for 12 hours to obtain a modified thermally conductive activated carbon. The specific surf...

Embodiment 2

[0062] Embodiment 2 of the present invention provides a kind of reduced tar cigarette paper and its preparation method, and this reduced tar cigarette paper is prepared according to the following method:

[0063] (1) Preparation of modified thermally conductive activated carbon:

[0064] (10) Immerse 200-mesh walnut shell powder into 0.3g / mL zinc chloride solution, the mass ratio of walnut shell powder and zinc chloride in the mixed solution is 1:1, and then react in a water bath at 80°C for 3 hours. The solid powder was dried in a vacuum oven at 120°C for 12 hours;

[0065] (20) Add 35% of 80-mesh expanded graphite to the dried solid powder and mix evenly, and press the mixture under 8MPa pressure;

[0066] (30) Carbonize the pressed mixture in an inert atmosphere at 600°C for 4.5 hours;

[0067] (40) Wash the carbonized product to neutrality and dry at 120°C for 12 hours to obtain a modified thermally conductive activated carbon. The specific surface area of the modified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com