Nitrogen and phosphorus co-doped biomass carbon/lithium iron phosphate composite material and preparation method thereof

A lithium iron phosphate, biomass carbon technology, applied in nanotechnology, electrochemical generators, nanotechnology and other directions for materials and surface science, can solve problems such as poor cycle performance and low conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] 1. A preparation method of nitrogen and phosphorus co-doped biomass carbon / lithium iron phosphate composite material, characterized in that the specific steps are as follows:

[0020] Step (1), take a fresh egg yolk and stir mechanically to obtain egg yolk liquid, and the speed is controlled at 50r / min;

[0021] In step (2), the egg yolk liquid obtained in step (1) and deionized water are mixed evenly according to the volume ratio of 0.5~2:1, and then the lithium iron phosphate precursor is added to the mixed solution with electromagnetic stirring until it is completely mixed evenly to obtain a viscous slurry;

[0022] Step (3), drying the slurry obtained in step (2) in a vacuum oven at a temperature of 60-80°C for 6-12 hours;

[0023] Step (4), put the dried sample obtained in step (3) into a crucible after grinding, and calcinate in a vacuum tube furnace at 600~750°C for 4~16h under the protection of argon to obtain nitrogen and phosphorus co-doped biomass carbon / ...

Embodiment 1

[0026] Step 1. Take a fresh egg yolk and mechanically stir it to obtain egg yolk liquid (the speed is controlled at 50r / min);

[0027] Step 2. Take 0.5mL egg yolk liquid and deionized water and mix evenly according to the volume ratio of 2:1, then add lithium iron phosphate precursor to the mixed solution and electromagnetically stir until completely mixed evenly to obtain a viscous slurry;

[0028] Step 3, drying the slurry obtained in step 2 in a vacuum oven at a temperature of 80° C. for 12 hours;

[0029] Step 4. Put the dried sample obtained in step 3 into a crucible after being ground, and in a vacuum tube furnace under the protection of an argon atmosphere, the heating rate is 5°C / min, and the calcination temperature is 650°C for 6h to obtain nitrogen-phosphorus co- Doped biomass carbon / lithium iron phosphate composite.

Embodiment 2

[0031] Step 1. Take a fresh egg yolk and mechanically stir it to obtain egg yolk liquid (the speed is controlled at 50r / min);

[0032] Step 2. Take 1mL of egg yolk liquid and deionized water and mix evenly according to the volume ratio of 1:1, then add the lithium iron phosphate precursor to the mixed solution and stir it until it is completely mixed evenly to obtain a viscous slurry;

[0033] Step 3, drying the slurry obtained in step 2 in a vacuum oven at a temperature of 80° C. for 12 hours;

[0034] Step 4. Put the dried sample obtained in step 3 into a crucible after being ground, and in a vacuum tube furnace under the protection of an argon atmosphere, the heating rate is 5°C / min, and the calcination temperature is 650°C for 6h to obtain nitrogen-phosphorus co- Doped biomass carbon / lithium iron phosphate composite.

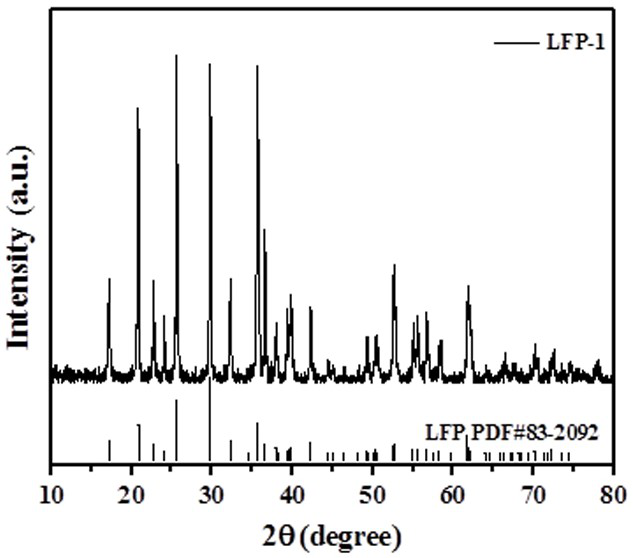

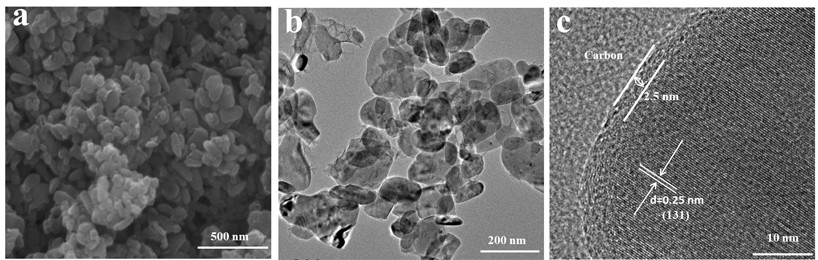

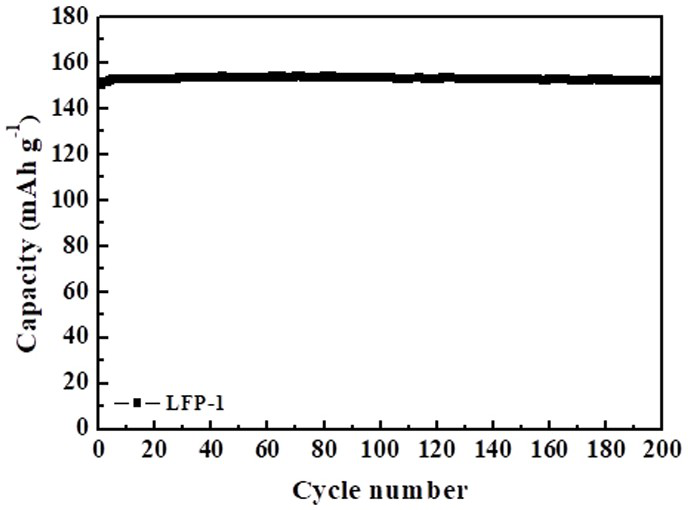

[0035] The X-ray diffraction pattern of nitrogen and phosphorus co-doped biomass carbon / lithium iron phosphate composite material prepared in this example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com