Rapid processing method of nutrition-enhanced stabilized rice bran

A processing method and enhanced technology, which is applied in cosmetics, pharmaceutical formulations, cosmetic preparations, etc., can solve problems such as increasing the cost of rice bran food utilization, destruction of active ingredients, and increase in water content of rice bran, so as to improve the stabilization effect, The effect of low processing temperature and extended shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

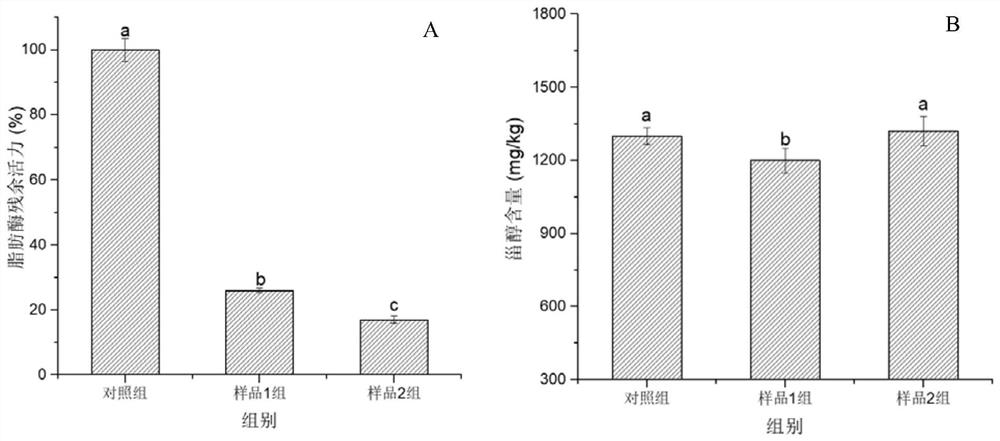

[0027] Grind and prepare fresh rice bran raw materials, weigh 500g of fresh rice bran, spread it on a tray with holes, and place it in a negative pressure steam heater (automatically controlled pulsating vacuum pressure steam sterilizer, model YZM-M60×70BI), Negative pressure and vacuum set the inner chamber pressure of the airtight container at -75kPa; high-temperature steam is introduced to realize temperature rise and perform stabilization treatment. The rice bran stabilization temperature is 105°C, the inner chamber pressure of the airtight container is 120kPa, and the treatment time is 15 minutes. After the rice bran stabilization treatment was completed, the rice bran was taken out to measure the residual lipase activity and sterol content of the rice bran. The untreated rice bran was used as a negative control (denoted as the control group), and the rice bran treated with traditional steam heating (121°C, 15min) was positive. Control (denoted as sample 1 group), carry ou...

Embodiment 2

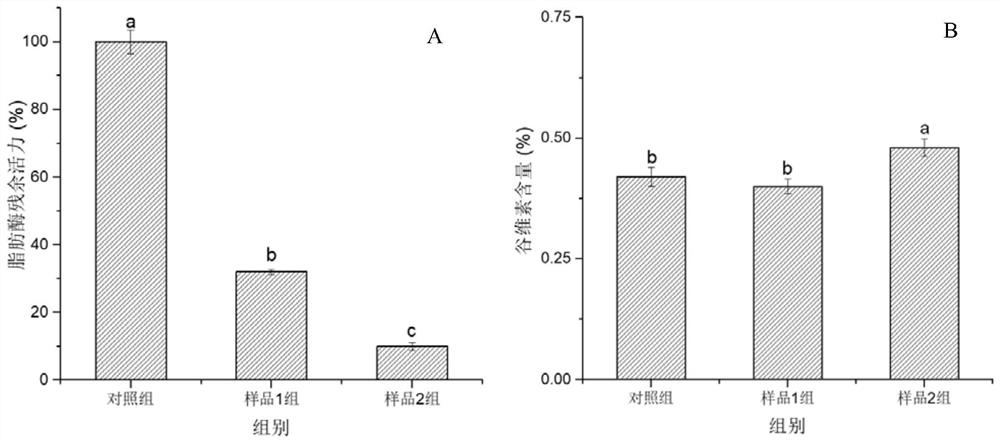

[0031] Grind and prepare fresh rice bran raw materials, weigh 500g of fresh rice bran, spread it on a tray with holes, and place it in a negative pressure steam heater (automatically controlled pulsating vacuum pressure steam sterilizer, model YZM-M60×70BI), Negative pressure and vacuum set the inner chamber pressure of the airtight container at -95kPa; high-temperature steam is introduced to realize temperature rise and perform stabilization treatment. The rice bran stabilization temperature is 115°C, the inner chamber pressure of the airtight container is 170kPa, and the treatment time is 10 minutes. After the rice bran stabilization treatment, the rice bran was taken out to measure the residual lipase activity and oryzanol content of the rice bran. The untreated rice bran was used as a negative control (denoted as the control group), and the rice bran treated with traditional steam heating (121°C, 10min) was positive. Control (denoted as sample 1 group), carry out 3 times re...

Embodiment 3

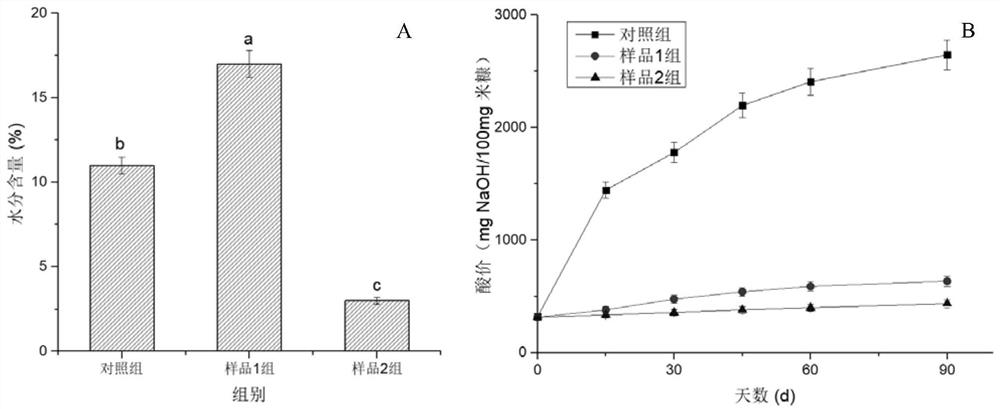

[0035] Grind and prepare fresh rice bran raw materials, weigh 500g of fresh rice bran, spread it on a tray with holes, and place it in a negative pressure steam heater (automatically controlled pulsating vacuum pressure steam sterilizer, model YZM-M60×70BI), Negative pressure and vacuum set the inner chamber pressure of the airtight container at -85kPa; high-temperature steam is introduced to realize temperature rise for stabilization treatment. The rice bran stabilization temperature is 110°C, the inner chamber pressure of the airtight container is 145kPa, and the treatment time is 12 minutes. After the rice bran stabilization treatment is completed, further start the drying procedure, and the relevant parameters are: the pressure of the inner chamber of the airtight container is -90kPa, the temperature of the inner chamber of the airtight container is 120°C, and the duration is 5 minutes. After drying, the water content of the rice bran was measured. Subsequently, the rice b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com