Small and medium-sized perishable garbage treatment device

A garbage treatment device, small and medium-sized technology, applied in the direction of sludge treatment, sedimentation treatment, special treatment goals, etc., can solve the problems of high water content of perishable garbage, difficulty in stable operation, high salt and oil content of products, and reduce the perishable garbage. Possibility of rotting garbage residue, improvement of normal filter mesh, and effect of increasing load-bearing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

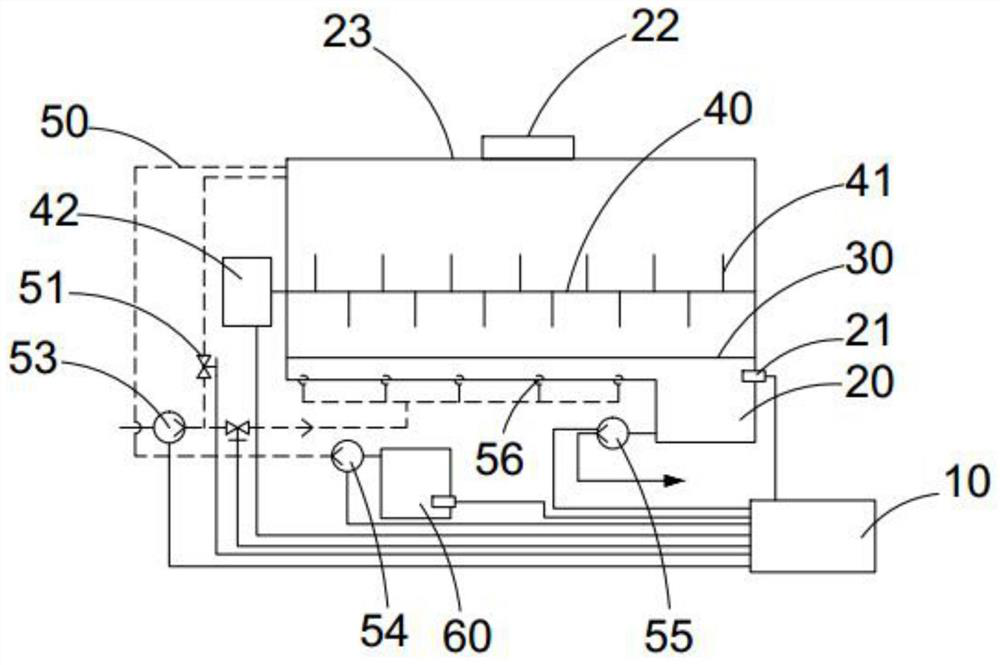

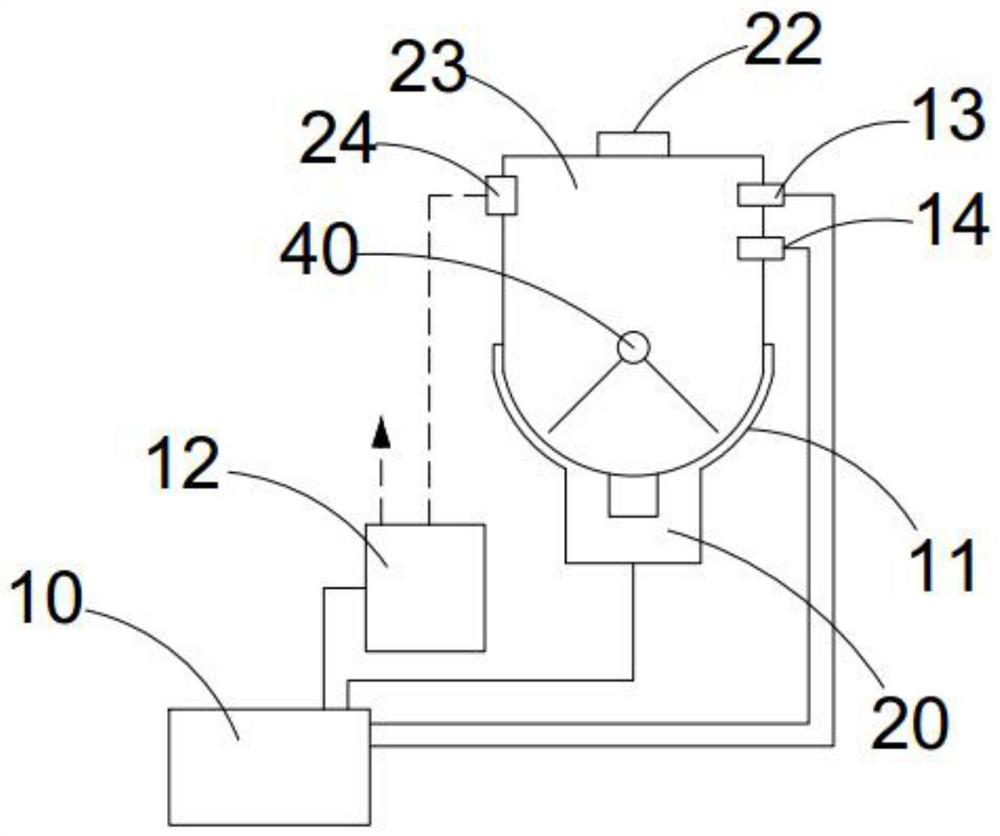

[0046] See attached Figure 1-2 As shown in and 11, small and medium-sized perishable waste disposal devices include:

[0047] A box body 23, the upper part of the box body 23 is provided with a feed inlet 22, the inner bottom surface of the box body 23 has a slope and the bottom of the slope is connected to a sewage collection box 20;

[0048] The bacterial agent box 60, the bacterial agent box 60 is located outside the casing 23, the bacterial agent box 60 communicates with the upper part of the casing 23 through the first transmission pipe body 50, and is used to connect the bacterial agent box 60 and the first transmission pipe of the casing 23 The body 50 is provided with a second pump body 54,

[0049] Stirring main shaft 40, stirring main shaft 40 is located in casing 23, is provided with stirring bar 41 alternately on stirring main shaft 40, and casing 23 is provided with the stirring motor 42 that is used to drive stirring main shaft 40,

[0050] The intelligent con...

Embodiment 2

[0071] The further optimization scheme of present embodiment on the basis of embodiment 1 is:

[0072] See attached Figure 4-10 As shown, the water outlet of the third pump body 55 is connected with a sewage primary filter box 70, and the side of the bottom of the sewage primary filter box 70 communicates with the exhaust port 24 through the second transmission pipe 15, and the sewage primary filter The upper side of the box 70 is connected with the deodorizing device 12 through the second transmission pipe body 15 . For the sewage obtained by the device through the hydrolysis of bacterial agents, the water body still contains a certain amount of impurities after passing through the filter, which does not meet the sewage discharge standards or the difficulty of subsequent sewage purification treatment is not low. By designing the sewage primary filter box 70 to deal with The sewage is subjected to primary filtration, and the gas generated during the hydrolysis process inside...

Embodiment 3

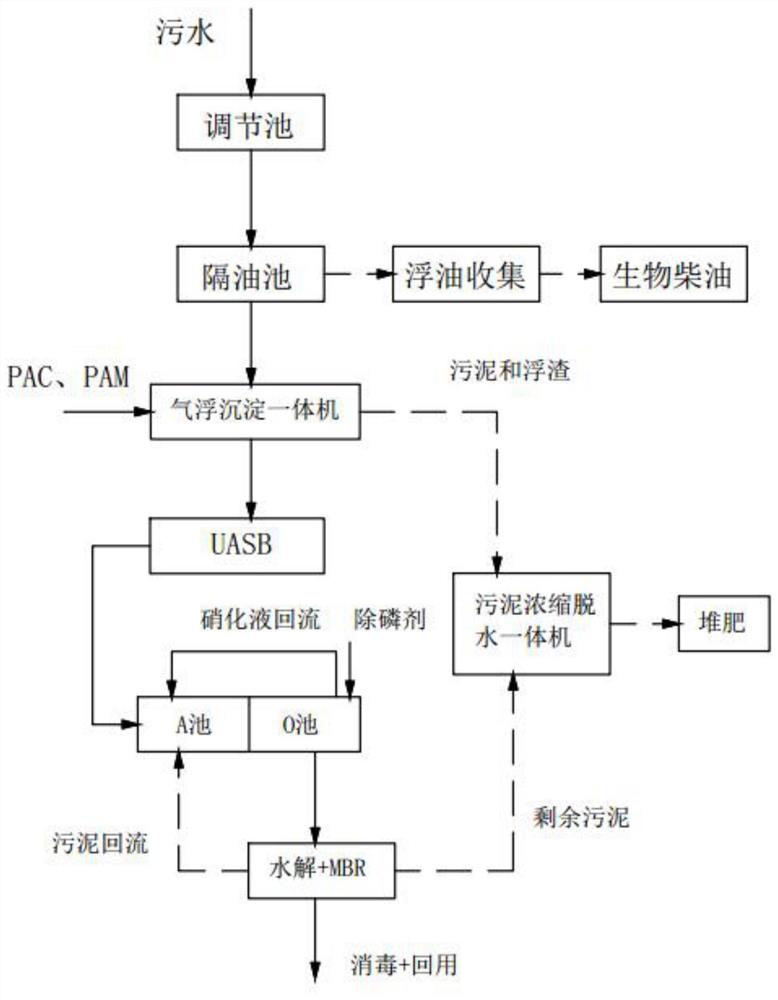

[0079] See attached image 3 As shown, the purification method of sewage obtained by using a small and medium-sized perishable garbage treatment device is as follows:

[0080] -Send the sewage into the adjustment tank for primary adjustment and sedimentation, send the water body after the primary adjustment and sedimentation to the grease trap, collect the slick oil in the water body in the grease trap, and use the collected slick oil to obtain biodiesel through biological treatment;

[0081] -The water discharged from the grease trap is sent to the integrated air flotation and sedimentation machine, and the sludge or scum obtained from the treatment is sent to the sludge concentration and dehydration integrated machine, and the dehydrated products are composted, and the air flotation and sedimentation integrated machine discharges the water Sent to UASB for further processing;

[0082] -The water obtained by UASB treatment is sent to the phosphorus removal tank to add phosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com