Waterproof dry-mixed mortar and production process thereof

A technology of dry-mixed mortar and production process, applied in the field of mortar production, which can solve the problems of high raw material cost, poor construction workability, poor impermeability, etc., and achieve good durability, reduce the amount of large particles or impurities, and good waterproof performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

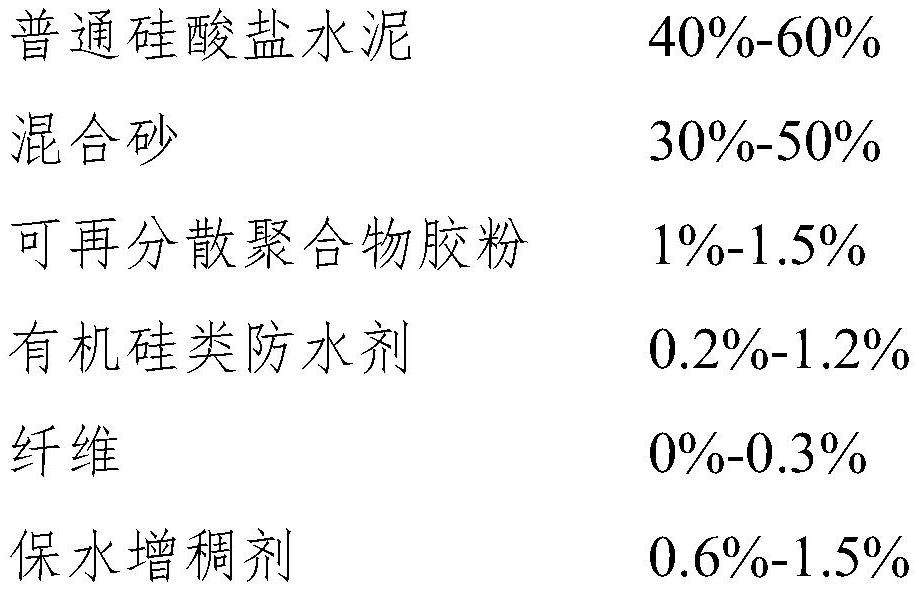

[0039] A waterproof dry-mixed mortar, comprising the following powders, the components are calculated as percentages by weight:

[0040]

[0041] The mixed sand includes yellow sand and improved powder, and the yellow sand replacement rate of the improved powder is 30-%-35%. The improved powder includes fly ash and stone powder, and the ratio of fly ash and stone powder is 5:1.

[0042] The redispersible polymer rubber powder is selected from HPMC-45000, and the silicone waterproofing agent is a composite siloxane formed by copolymerization of polydimethylsiloxane and long carbon chain alkylpolysiloxane.

[0043] The water-retaining thickener is formed by mixing starch ether, cellulose ether and bentonite, and the mixing ratio of the starch ether, cellulose ether and bentonite is 1:4:10.

[0044]The additives include expansion agent and water reducer, the weight percentage of the expansion agent is 6.5%, and the rest is water reducer.

[0045] The expansion agent is calciu...

Embodiment 2

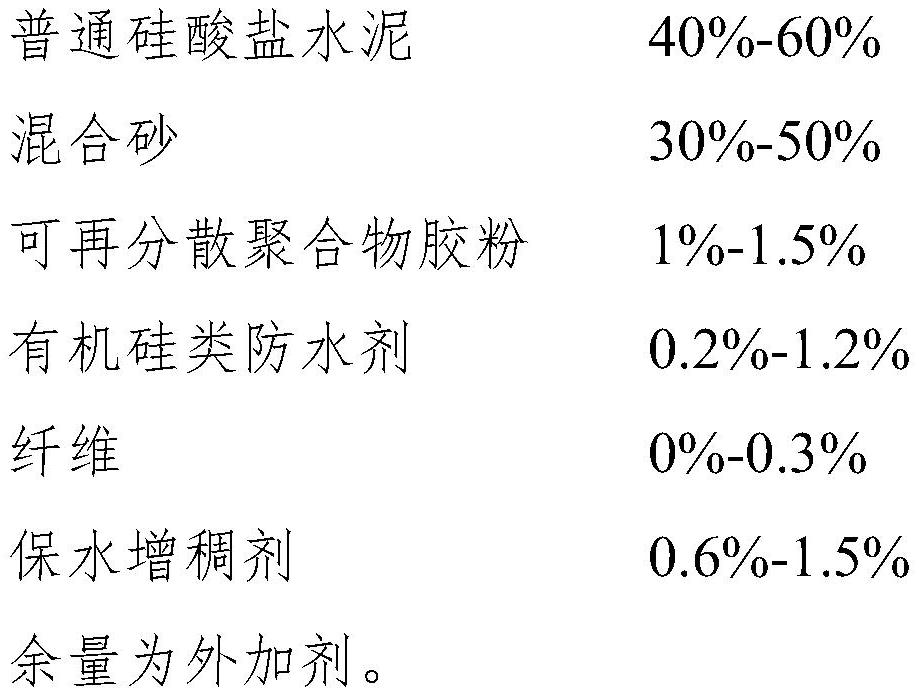

[0048] A waterproof dry-mixed mortar, comprising the following powders, the components are calculated as percentages by weight:

[0049]

[0050]

[0051] The mixed sand includes yellow sand and improved powder, and the yellow sand replacement rate of the improved powder is 30-%-35%. The improved powder includes fly ash and stone powder, and the ratio of fly ash and stone powder is 5:1.

[0052] The redispersible polymer rubber powder is selected from HPMC-45000, and the silicone waterproofing agent is a composite siloxane formed by copolymerization of polydimethylsiloxane and long carbon chain alkylpolysiloxane.

[0053] The water-retaining thickener is formed by mixing starch ether, cellulose ether and bentonite, and the mixing ratio of the starch ether, cellulose ether and bentonite is 1:4:10.

[0054] The admixture comprises an expansion agent and a water reducer, the weight percentage of the expansion agent is 8%, and the rest is a water reducer.

[0055] The expan...

Embodiment 3

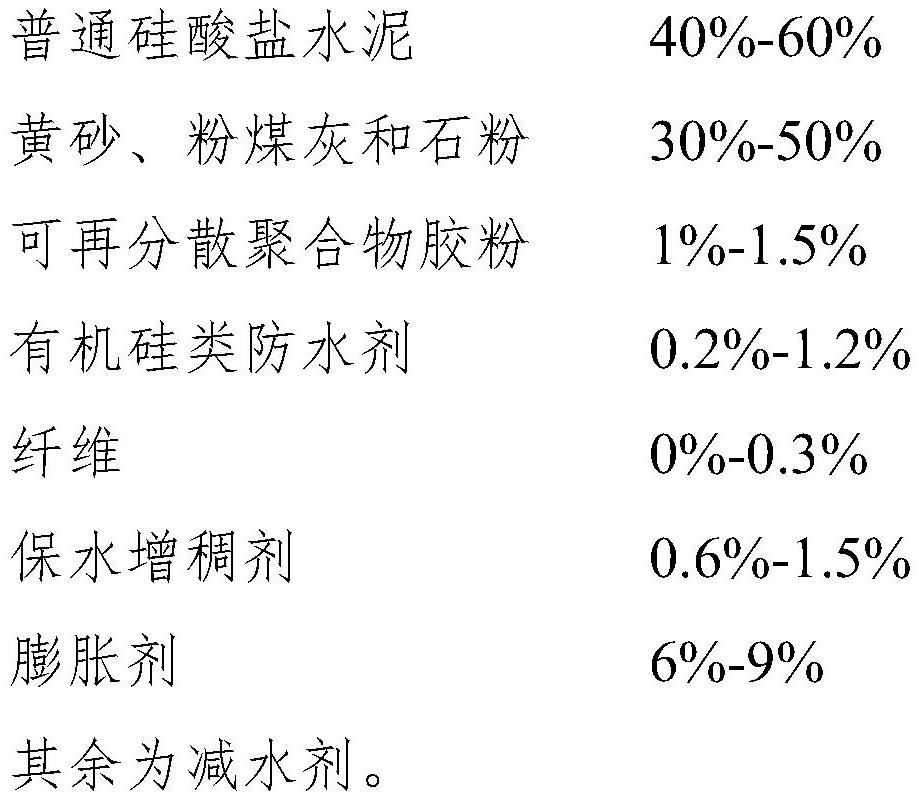

[0058] A waterproof dry-mixed mortar, comprising the following powders, the components are calculated as percentages by weight:

[0059]

[0060] The mixed sand includes yellow sand and improved powder, and the yellow sand replacement rate of the improved powder is 30-%-35%. The improved powder includes fly ash and stone powder, and the ratio of fly ash and stone powder is 5:1.

[0061] The redispersible polymer rubber powder is selected from HPMC-45000, and the silicone waterproofing agent is a composite siloxane formed by copolymerization of polydimethylsiloxane and long carbon chain alkylpolysiloxane.

[0062] The water-retaining thickener is formed by mixing starch ether, cellulose ether and bentonite, and the mixing ratio of the starch ether, cellulose ether and bentonite is 1:4:10.

[0063] The admixture comprises an expansion agent and a water reducer, the weight percentage of the expansion agent is 6%, and the rest is a water reducer.

[0064] The expansion agent i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com