A kind of preparation method of controlled-release antibacterial packaging fiber film with ph intelligent response

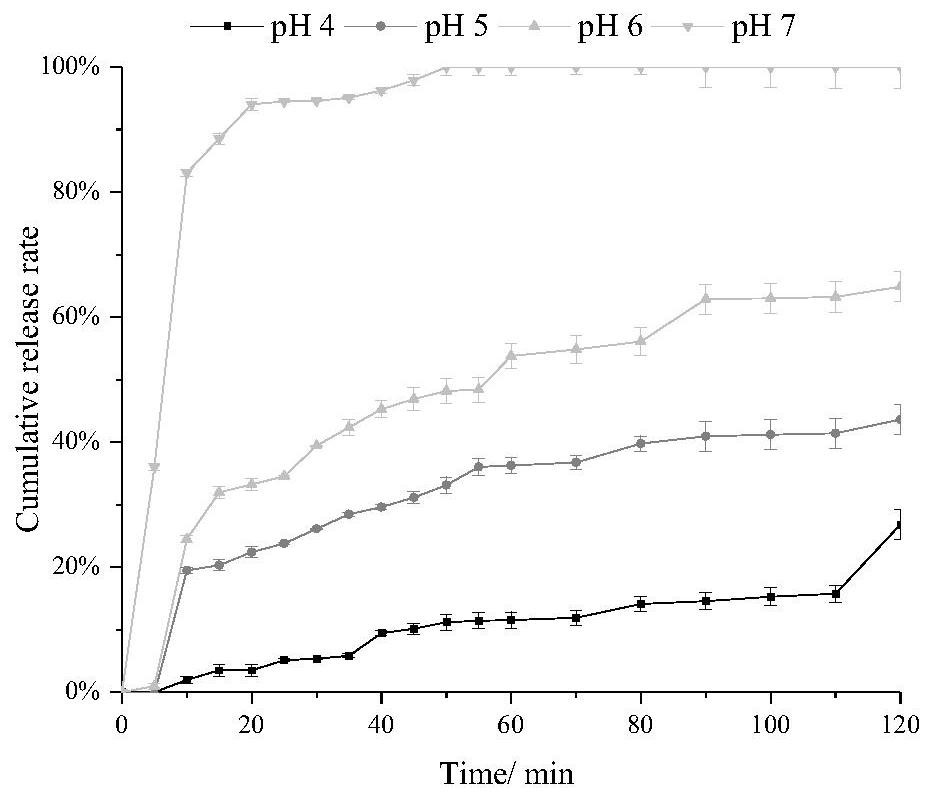

A fiber film and intelligent technology, applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve problems such as excessive addition of antibacterial agents, out-of-sync release of antibacterial ingredients, and difficulty in achieving high-efficiency effects in food antibacterial packaging technology. To achieve the effect of improving the effective contact area and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

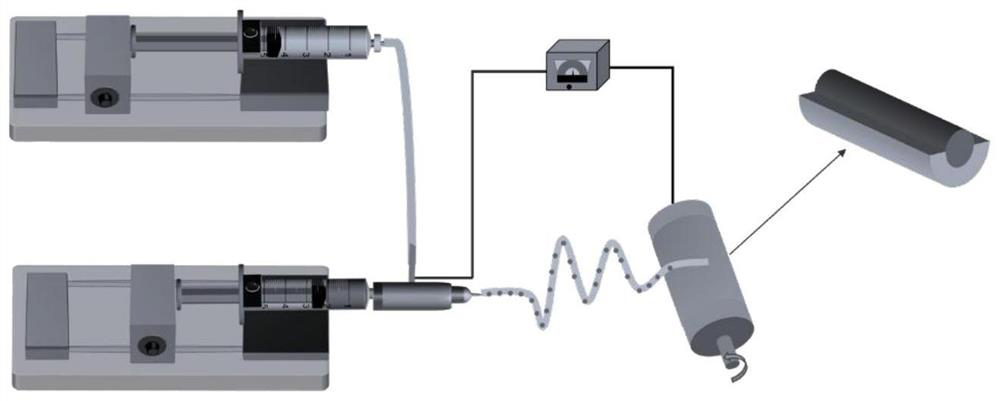

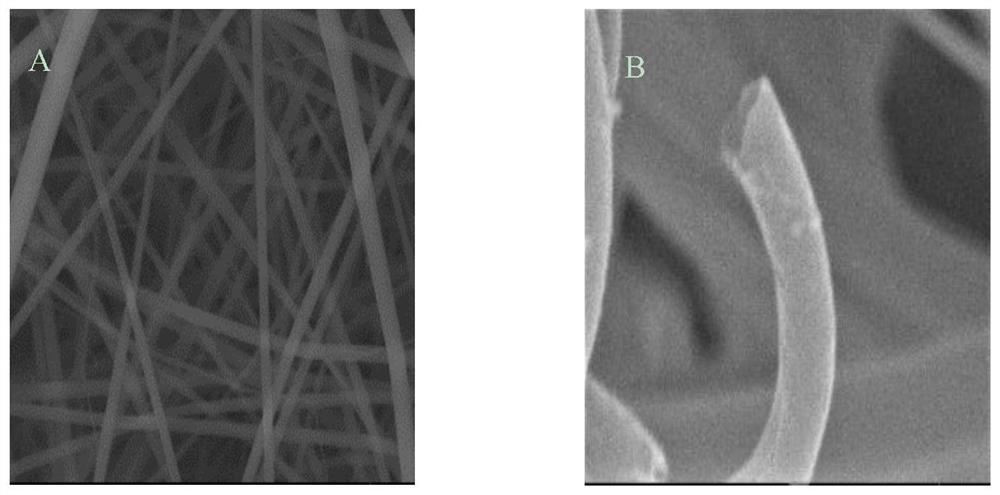

[0031] A method for preparing a controlled-release antibacterial packaging fiber film with pH intelligent response, using coaxial electrospinning technology, comprising the following steps:

[0032] (1) Preparation of spinning solution

[0033] ① Preparation of shell solution: Dissolve 2g of Eudragit L100-55 in 20mL of 80% ethanol-water solution, then add 0.2g of sodium citrate for blending, seal and stir until completely dissolved to obtain a mixed solution;

[0034] ②Preparation of nuclear layer solution: dissolve 0.05mL of cinnamon essential oil in 10mL of ethyl acetate to dilute, and stir evenly;

[0035] (2) Preparation of fiber membrane

[0036]Using coaxial electrospinning technology, inject the shell layer solution and the obtained core layer solution into the syringe respectively; the corresponding technical condition parameters are: the voltage applied by the high-voltage power supply is 15kV, the receiving distance is 10cm, and the core layer solution The propulsi...

Embodiment 2

[0049] A method for preparing a pH intelligent response controlled-release antibacterial packaging fiber film, using coaxial electrospinning technology, comprising the following steps:

[0050] (1) Preparation of spinning solution

[0051] ① Preparation of shell solution: Dissolve 3g of Eudragit L100-55 in 20mL of 85% ethanol-water solution, then add 0.1g of citric acid to blend, seal and stir until completely dissolved to obtain a mixed solution;

[0052] ②Preparation of nuclear layer solution: dissolve 0.1mL of oregano essential oil in 10mL of Tween 80 to dilute, and stir well;

[0053] (2) Coaxial electrospinning technology is used for the preparation of the fiber membrane, and the shell solution and the obtained core solution are injected into the syringe respectively; the corresponding technical condition parameters are: the voltage applied by the high-voltage power supply is 23kV, and the received The distance is 20cm, the advancing rate of the core solution is 0.2mL / h,...

Embodiment 3

[0064] A method for preparing a pH intelligent response controlled-release antibacterial packaging fiber film, using coaxial electrospinning technology, comprising the following steps:

[0065] (1) Preparation of spinning solution

[0066] ①Preparation of shell solution: Dissolve 2.5g of Eudragit L100-55 in 20mL of 90% ethanol-water solution, then add 0.12g of disodium hydrogen phosphate for blending, seal and stir until completely dissolved to obtain a mixture solution;

[0067] ②Preparation of nuclear layer solution: dissolve 0.07mL of thyme essential oil in 10mL of ethanol to dilute, and stir evenly;

[0068] (2) Preparation of fiber membrane

[0069] Using coaxial electrospinning technology, completely dissolve the shell solution and the core solution obtained in step ① and inject them into the syringe respectively; the corresponding technical parameters are: the voltage applied by the high voltage power supply is 18kV, the receiving distance is 15cm, The propulsion rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com